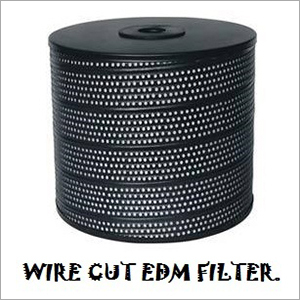

EDM Filter

EDM Filter Specification

- Connecting Type

- End Cap / Threaded

- Pressure

- 0.2-3 MPa

- Efficiency (%)

- Up to 99%

- Media Type

- Depth filter

- Filtration Grade

- Fine / Precision

- Flow Rate

- 30 - 150 L/min

- Filter Type

- Cartridge / Cylinder Type

- Capacity

- Depends on Model & System (up to 8000 litres)

- Cleaning Method

- Replaceable

- Temperature Range

- -20C to 80C

- Condition

- New

- Material

- Paper, Stainless Steel, Fiberglass

- Mesh

- 10 to 60 micron

- Diameter

- 50 mm to 200 mm

- Construction

- Cylindrical, Pleated, Rigid

- Medium Filter

- EDM Oil, Dielectric Fluid

- Weight

- Approx. 250 g to 1 kg

- Shape

- Round

- Feature

- Long Service Life, Corrosion Resistance, High Filtration Accuracy, Easy Installation, Low Maintenance

About EDM Filter

We are engaged in providing high quality EDM Filter. These are being designed by our well qualified team of experts. Our range of filter is highly appreciated because of its high quality with perfection to finish. It can also be customized as per the stated specification of our valued customers. The filters are checked on stringent quality parameters to ensure good filtration efficiency, temperature resistance and longer service life. We offer the EDM Filter customized as per the requirements of the customer.

Salient Features

- Good filtration efficiency

- Temperature resistance

- Longer service life

- Robust construction

Specifications:

For E.D.M Machine:

| Specifications | |

| Liquid to be Filtered: | E.D.M Oil |

| Porosity Available: | 10 & 20 Micron |

| Filtration Media: | Filter Paper |

For Wire Cut Machine:

| Specifications | |

| Liquid to be Filtered: | Distil Water |

| Porosity Available: | 3,5,7,10 & 20 Micron |

| Filtration Media: | Filter Paper |

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Superior Filtration for Precision EDM Applications

Engineered for wire cut and sinker EDM machines, this filter guarantees high filtration accuracy and dependable contaminant removal. Its sturdy construction supports resistance to corrosion, high pressure, and temperature fluctuations, delivering consistent performance for industrial applications.

Adaptable Design for Versatile Usage

With customizable color options and a choice between plastic or stainless steel end caps, the filter integrates effortlessly into diverse EDM filtration systems. Available in various diameters and mesh sizes, the design ensures smooth compatibility with different machines and filtration needs.

Long Service Life and Low Maintenance

Featuring premium materials and a pleated structure, this filter achieves up to 99% efficiency while maintaining a long operating life of up to 200 hours. Its replaceable design and robust construction minimize maintenance requirements, saving both time and operational costs.

FAQs of EDM Filter:

Q: How do I properly install the EDM filter in my wire cut or sinker EDM machine?

A: Installation is straightforward: simply place the filter in the designated cartridge or cylinder slot in your EDM machine, ensuring the end cap seals securely with either the rubber or silicone gasket provided. Refer to your machines manual for specific guidance based on the model.Q: What materials are used in the construction of this EDM filter, and how does that benefit performance?

A: The EDM filter combines materials like paper, stainless steel, and fiberglass, forming a rigid cylindrical or pleated shape. This results in superior fine or precision filtration, enhanced corrosion resistance, and reliability under high-pressure and high-temperature conditions.Q: When should I replace the EDM filter to maintain optimal efficiency?

A: The filter is designed for an operational life of up to 200 hours. Replace it sooner if you observe reduced flow rate, increased system pressure, or lower filtration performance to ensure your EDM system continues operating at peak efficiency.Q: Where can this filter be used, and is it compatible with all types of dielectric fluids?

A: This EDM filter is suitable for wire cut and sinker EDM machines, as well as industrial EDM filtration systems. It is designed for use with EDM oil, dielectric fluids, and other compatible media, offering reliable filtration across a wide range of applications.Q: What is the filtration process, and how effective is it in removing contaminants?

A: The filter operates as a depth filter, utilizing a precision mesh from 10 to 60 microns to trap contaminants. Its pleated design and fine filtration grade allow it to achieve up to 99% efficiency, ensuring clean fluid for your EDM processes.Q: How does the EDM filter contribute to reduced maintenance and longer machine life?

A: By delivering high-filtration accuracy and capturing microscopic contaminants, the EDM filter helps protect sensitive EDM equipment. Its robust and easy-to-replace design means fewer interruptions, lower maintenance frequency, and extended machine life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Manufacturers In India Delhi Category

Carbon Filter

Filter Type : Cartridge Filter

Feature : High adsorption capacity, Removes Odor and Impurities, Easy Installation

Shape : Cylindrical

Construction : Other, Cylindrical, Perforated Outer Shell

Condition : New

Material : Activated Carbon, Stainless Steel Body

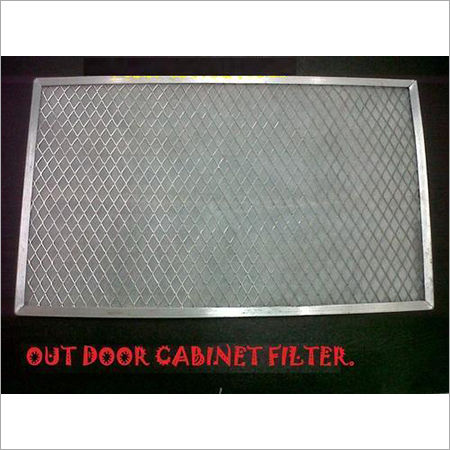

Out Door Cabinet Filter

Filter Type : Panel Filter

Feature : High dust holding capacity, easy to install, weatherresistant

Shape : Rectangular

Construction : Other, Robust, welded frame

Condition : New

Material : Galvanized Steel Frame, Synthetic Fiber Media

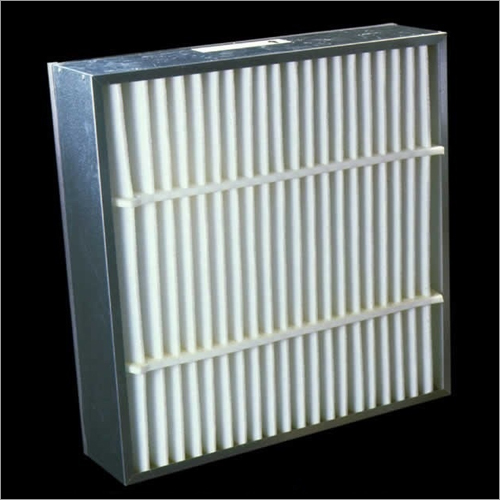

Cabinet Air Filter

Filter Type : Panel Air Filter

Feature : High dust holding capacity, Low resistance, Easy installation, Durable construction

Shape : Rectangular

Construction : Other, Panel Type, Pleated Design

Condition : New

Material : Galvanized Steel Frame, Synthetic Fiber Media

Pre Filter

Filter Type : Panel Filter

Feature : Long Life Low Resistance

Shape : Rectangular

Construction : Other, Rigid Frame

Condition : New

Material : Aluminum Synthetic Media

Send Inquiry

Send Inquiry