Suction Strainer Filter

Suction Strainer Filter Specification

- Flow Rate

- From 50 LPM to 500 LPM (depending on size)

- Pressure

- Max 10 Bar

- Filtration Grade

- Medium / Fine

- Filter Type

- Suction Strainer

- Media Type

- Oil, Water-based Fluid

- Temperature Range

- -20C to +120C

- Efficiency (%)

- Up to 98%

- Capacity

- Varies with model

- Connecting Type

- Threaded, Flanged

- Cleaning Method

- Washable/Reusable

- Condition

- New

- Material

- Stainless Steel, Mild Steel

- Mesh

- Available in various mesh sizes (usually 60-300 mesh)

- Diameter

- Standard sizes 1 to 8 (customizable)

- Construction

- Welded, Seamless

- Medium Filter

- Liquids, Hydraulic Oil

- Weight

- 250g to 2kg (depending on size)

- Shape

- Round, Cylindrical

- Feature

- Durable construction, High dirt holding capacity, Easy to install and maintain

About Suction Strainer Filter

Features

- Suction strainers are available from a flow rate of 5 to 250 lpm.

- Filters are available from 10 microns to 150 microns filtration rating

- Fitted with Filter caps and Filter media

- Die cast aluminium nut and caps are installed

- Stainless steel wire mesh and perforated steel core

Specification

- Flow rate

- Suction strainers are available from a flow rate of 5 to 250 lpm.

- Nominal particle rating

- Filters are available from 10 microns to 150 microns filtration rating

- Filter caps

- Die cast aluminium nut and caps are installed

- Filter media

- Stainless steel wire mesh and perforated steel core.

- Sealant

- Epoxy based

- Sizes

- Custom build sizes are offered

- Operating conditions

- Filter can withstand temperature up to 120 ºC. Filter is washable or can be cleaned by applying air pressure and reused.

ENVIRO TECH suction strainer filters are most suited for filtration of:

- petroleum-based hydraulic fluids,

- phosphate esters,

- water glycols,

- lubricating oils,

- coolants,

- fuels and water in fluid reservoirs,

- sumps and similar applications.

- They are widely used in automobile, molding and allied engineering industries.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Reliable Contaminant Protection

These filters prevent dirt and debris from entering hydraulic systems, safeguarding pumps and key components. Their robust construction and efficient filtration help prolong equipment lifespan, minimize downtime, and reduce maintenance costs, making them ideal for industrial applications.

Versatile Installation Options

Suction strainer filters offer flexibility with threaded (BSP/NPT) and flanged connections, as well as options for inline or reservoir-mounted assembly. This adaptability ensures compatibility with diverse system requirements, enhancing operational efficiency and convenience during setup.

Wide Range of Materials & Mesh Sizes

Constructed from stainless steel or mild steel, these filters feature mesh sizes from 60 to 300, which support multiple filtration needs. Customers can choose from various diameters, shapes, and finishes, including metallic silver or custom coatings, to suit specific industrial setups.

FAQs of Suction Strainer Filter:

Q: How does the suction strainer filter protect hydraulic pumps and components?

A: The filter effectively captures contaminants present in hydraulic fluids before they reach critical system components, reducing wear, blocking harmful particles, and helping prevent equipment failure. This process ultimately extends the life of pumps and other hydraulic machinery.Q: What are the available installation options for suction strainer filters?

A: Suction strainer filters can be installed inline with piping or reservoir-mounted, and are offered with either threaded (BSP/NPT) or flanged end connections. These options allow compatibility with a variety of hydraulic system layouts.Q: When should I clean or replace the suction strainer filter?

A: Cleaning or replacement should be performed as part of routine maintenance, typically when the filter shows significant clogging or reduced flow rate. The washable and reusable design enables easy upkeep to maintain filtration efficiency.Q: Where are these filters typically used?

A: These filters are commonly employed in industrial settings, such as hydraulic systems, reservoirs, and suction filter assemblies for machinery, ensuring clean fluid supply and equipment protection.Q: What are the benefits of choosing a filter with a high micron rating and dirt holding capacity?

A: A higher micron rating balances fine filtration with optimal flow rate, while high dirt holding capacity means fewer maintenance intervals and longer operational uptime for your system.Q: How do I select suitable materials and mesh sizes for my application?

A: Select stainless steel for enhanced corrosion resistance or mild steel for standard applications. Mesh sizes (60300) and micron ratings (25300) should match the required filtration levels, fluid type, and operating environment of your hydraulic system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Manufacturers In India Delhi Category

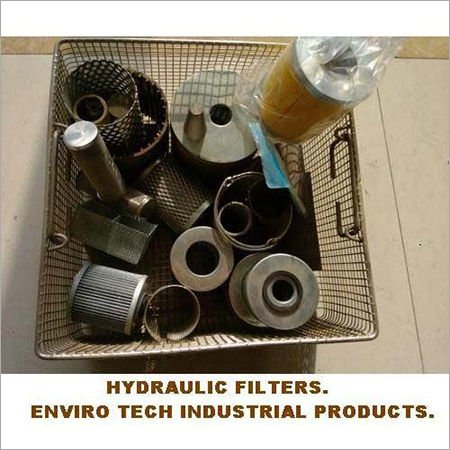

Hydraulic Filters

Construction : Other, Cylindrical, Welded Seam

Condition : New

Feature : Removes particulate contaminants from hydraulic oil, Easy installation, Enhanced durability

Filter Type : Return Line / Suction / Pressure line

Shape : Cylinder

Filtration Grade : Other, Medium to High

Carbon Filter

Construction : Other, Cylindrical, Perforated Outer Shell

Condition : New

Feature : High adsorption capacity, Removes Odor and Impurities, Easy Installation

Filter Type : Cartridge Filter

Shape : Cylindrical

Filtration Grade : Other, Pre Filter

Telecom Racks Foam Air Filter

Construction : Other, Rugged frame with foam media

Condition : New

Feature : High dust holding capacity, reusable, washable

Filter Type : Air Filter

Shape : Rectangular

Filtration Grade : Other, Prefilter

RRR Oil Filter Elements

Construction : Other, Seamless, pleated or cylindrical

Condition : New

Feature : High dirt holding capacity, corrosionresistant structure, easy installation, long service life

Filter Type : Oil Filter Element

Shape : Cylindrical

Filtration Grade : Other, Fine to ultrafine

Send Inquiry

Send Inquiry