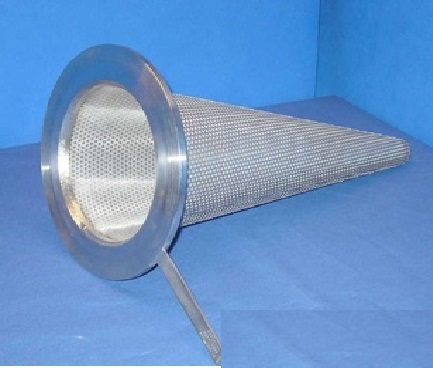

Sintered Mesh Cone Filter

Sintered Mesh Cone Filter Specification

- Cleaning Method

- Back-flushing, Ultrasonic Cleaning, Chemical Cleaning

- Temperature Range

- -200C to 600C

- Media Type

- Liquid and Gas

- Flow Rate

- 0.530 m/h depending on dimensions

- Connecting Type

- Flanged/Threaded/Clamp/Fit-on

- Pressure

- Up to 15 bar

- Filter Type

- Sintered Mesh Filter

- Filtration Grade

- High Precision

- Capacity

- Varies by size; customizable

- Efficiency (%)

- Up to 99%

- Condition

- New

- Material

- Stainless Steel (SS 304/316L)

- Mesh

- Multi-layer Sintered Woven Mesh

- Diameter

- Customized, typically 25mm to 250mm

- Construction

- Cone (Conical) Shape, Seamless Welding

- Medium Filter

- Liquid and Gas

- Weight

- Depends on size; 100g to 2.5kg

- Shape

- Cone

- Feature

- High-Durability, Corrosion Resistant, Precise Filtration

Sintered Mesh Cone Filter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Middle East, South America, Western Europe, Africa, Central America, Eastern Europe, Asia, North America, Australia

- Main Domestic Market

- All India

About Sintered Mesh Cone Filter

Sintered Mesh Cone Filter- Category:Filter Strainer

- Material:Stainless Steel 304,316,202 or as per your request.

- Properties:Filter Strainer

- Application:Distillation, Absorption, Evaporation and Filtration Process of Rubber, Plastic Industry, The Screening of Grain and Oil

- tag:Sintered Mesh,Cone Filter,Stainless Steel,

Multi-Layer Sintered Construction

Featuring a sophisticated 5-layer composition, the sintered mesh cone filter provides a precise balance between protection, filtration accuracy, and longevity. Each layer is meticulously woven and bonded for optimal mechanical stability and flow distribution.

Versatile Industrial Applications

This filter is widely utilized in pharmaceuticals, chemical and petrochemical processing, food and beverage industries, and hydraulic systems. Its robust build, resistance to acids, alkalis, and oxidation ensures reliable operation in demanding environments.

Highly Customizable Design

From DN10 to DN250 standard sizes and custom diameters (25mm250mm), end connectionsflanged, threaded, clamp, or fit-oncan be tailored to suit diverse installation requirements. Finishes are available in polished or matte to fit system aesthetics or functional needs.

Effortless Maintenance and Longevity

Designed for longevity and minimal upkeep, the filter can be cleaned using back-flushing, ultrasonic, or chemical methods. Its stainless steel construction supports repeated use without compromising filtration efficiency or structural integrity.

FAQs of Sintered Mesh Cone Filter:

Q: How does the 5-layer structure enhance filtration performance in cone filters?

A: The 5-layer sintered mesh structure integrates protective, filtration, dispersion, and support layers, ensuring high filtration precision while maintaining structural integrity. This multi-layered approach allows for uniform flow, optimal particle retention (1200 microns), and extended filter life.Q: What types of industries commonly use sintered mesh cone filters, and why?

A: Industries such as pharmaceuticals, chemical processing, petrochemicals, food & beverage, and hydraulic systems use these filters due to their high durability, resistance to corrosion and chemicals, low maintenance, and suitability for both liquid and gas media.Q: When should a sintered mesh cone filter be cleaned or replaced?

A: These filters are designed for reusability and low maintenance. Cleaning should be performed when the flow rate decreases or pressure drop increases, using back-flushing, ultrasonic, or chemical cleaning. Replacement is rarely needed unless the mesh becomes damaged.Q: Where can the sintered mesh cone filter be installed for optimal performance?

A: Install the filter at fluid or gas entry points in process streams within reactors, pipelines, or filtration units. Customizable end connections (flanged, threaded, clamped, fit-on) ensure compatibility with various system configurations in India and other global markets.Q: What benefits does stainless steel construction offer for this filter type?

A: Stainless steel (SS 304/316L) offers excellent corrosion and oxidation resistance, robust mechanical stability, wide temperature tolerance (-200C to 600C), and longevity, making the filter suitable for severe industrial environments and prolonged use.Q: How do you select the appropriate micron rating and size for your application?

A: Choose a micron rating between 1200 microns based on the required particle retention and process media. Select the filter size (diameter and connection type) according to system flow rate, installation points, and process conditions to ensure efficient filtration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Filters Manufacturers - Industrial Air Filters Category

CYLINDRICAL FILTER CARTRIDGE

Media Type : Other, SS mesh, synthetic fiber optional

Diameter : Customizable (Standard: 60mm 300mm)

Temperature Range : 10C to +120C

Cleaning Method : Other, Backwash or ultrasonic cleaning

Shape : Cylindrical

Weight : 350g 1.2kg (depends on size)

CONICAL & CYLINDRICAL CARTRIDGE

Media Type : Other, Water, oil, chemicals, gases

Diameter : 25 mm to 160 mm

Temperature Range : 10C to 120C

Cleaning Method : Other, Washable, reusable

Shape : Conical & Cylindrical

Weight : Varies from 150g to 1.2kg depending on size

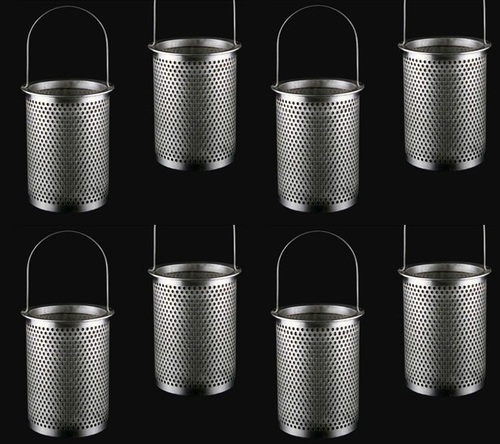

Filter Baskets

Media Type : Other, Liquid / solid filtration

Diameter : 100 mm to 600 mm (custom options available)

Temperature Range : 10C to +180C

Cleaning Method : Other, Manual / backwash / replaceable basket

Shape : Basket / cylindrical / conical

Weight : 2 Kg to 10 Kg (varies with size)

Stainless Steel Mesh Filter Basket

Media Type : Other, Water, Oil, Chemical, Air

Diameter : Approx. 100300 mm (custom sizes available)

Temperature Range : 20C to 400C

Cleaning Method : Other, Manual or Ultrasonic Cleaning

Shape : Cylindrical Basket

Weight : Approx. 250800 g (depends on size)

Send Inquiry

Send Inquiry