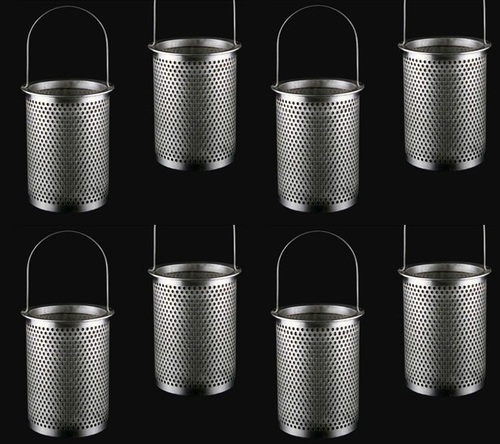

Filter Baskets

Filter Baskets Specification

- Temperature Range

- -10°C to +180°C

- Capacity

- Up to 500 liters

- Flow Rate

- 10 - 100 m3/h (customizable)

- Pressure

- Up to 16 bar

- Cleaning Method

- Manual / backwash / replaceable basket

- Efficiency (%)

- Up to 98% depending on mesh

- Media Type

- Liquid / solid filtration

- Connecting Type

- Flanged / threaded / clamp

- Filter Type

- Basket Filter

- Filtration Grade

- Fine / coarse (application based)

- Condition

- New

- Material

- Stainless Steel / Mild Steel

- Mesh

- Fine mesh (customizable as per requirement)

- Diameter

- 100 mm to 600 mm (custom options available)

- Construction

- Perforated Basket with optional mesh lining

- Medium Filter

- Weight

- 2 Kg to 10 Kg (varies with size)

- Shape

- Basket / cylindrical / conical

- Feature

- High capacity filtration, robust design, easy installation, corrosion resistant

Filter Baskets Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Filter Baskets

Filter Basket also named replacement strainer is made of perforated mesh or woven mesh. It can be divided into standard filter basket and slanted Filter Basket. Mesh Filter basket is available in various levels of mesh and micron requirement. In order to maximize the usable surface area of the filter basket, the holes are perforated in a staggered pattern. All the types filter basket has a lift-out handle and a solid, flat bottom. They feature high liquid capacity and high flow rate.

Specification:

Material: SS 302, 304, 304L, 316, 316L, etc.

Types: standard filter basket and slanted filter basket.

Filer media: perforation mesh or weave mesh.

Mesh: 20, 30, 40, 50, 60, 70, 80, 100, 150, 200.

Micron line mesh: 40, 90, 160, 250 industry use, 5, 10, 15, 25 light-duty for special use.

Perforation holes size: 1/2", 3/8", 1/4", 3/16", 9/64", 3/32", 1/16", 3/64".

Diameter and length: customized by requirements.

Feature:

Attractive appearance.

Good filtration effect.

High tensile strength.

Acid and alkali resistance.

Excellent corrosion and hot resistance.

Non-toxic and harmless

Easy to clean.

Long time service.

Application:

Food industry.

Metallurgy industry.

Chemical industry.

Petroleum industry.

Hydraulic oil.

Sewage filtration.

Chemical fiber.

Versatile Filtration Solutions

These filter baskets offer extensive adaptability for various industries. With customizable mesh sizes and diameters, they can be tailored for your unique process demandswhether you require fine filtration for pharmaceuticals or robust handling for oil and gas applications. Compliance with industrial standards assures reliable performance.

Durable Construction and Longevity

Manufactured from high-quality stainless steel or mild steel, the baskets are designed for durability and corrosion resistance. Both polished and epoxy-coated finishes are available, with a robust design supporting pressures up to 16 bar and temperature ranges from -10C to +180C. Service life ranges from 5 to 10 years, minimizing maintenance frequency.

Ease of Installation and Maintenance

Featuring vertical or horizontal mounting, a variety of connection types (flanged, threaded, clamp), and simple cleaning methods (manual, backwash, or replaceable baskets), these filters are engineered for user convenience. Spare baskets and custom packaging (box, crate, or tailored) further streamline integration into any workflow.

FAQs of Filter Baskets:

Q: How can I select the appropriate mesh size for my filter basket application?

A: Mesh size can be specified based on the required filtration grade, whether fine or coarse. Our offerings are customizable to suit your application, ensuring optimal filtration efficiency for water, oil, chemicals, or solid-liquid separation processes.Q: What industries can benefit from using these filter baskets?

A: These filter baskets are engineered for broad industrial use, including pharmaceutical, chemical processing, water treatment, oil and gas, and food processing sectors. Their customization options and high efficiency make them ideal for various liquid and solid filtration needs.Q: When should I replace or clean the filter basket?

A: Replacement or cleaning frequency depends on the filtration load and medium. Most users clean baskets via manual or backwash methods when flow rate drops, with replacement recommended every 510 years or as per process demands. Spare baskets are readily available.Q: Where can the filter baskets be installed in an industrial process?

A: They are designed for installation in line with liquid, oil, or chemical flows, using vertical or horizontal mounting. The broad range of connection types (flanged, threaded, clamp) facilitates integration into both new and existing systems.Q: What customization options are available for these filter baskets?

A: Customers can request tailored mesh sizes, basket shapes (cylindrical, conical, or standard), diameters (100600 mm), materials (stainless or mild steel), surface finishes, and basket depths. This ensures compatibility with process specifications and space constraints.Q: How does the robust design of the basket benefit industrial operations?

A: The strong construction offers stability at pressures up to 16 bar and temperatures from -10C to +180C, providing reliable filtration with minimal downtime. Corrosion-resistant materials and high-capacity designs enable continuous use in demanding environments.Q: What is the process for ordering and receiving customized filter baskets?

A: To order, share your specifications regarding mesh size, dimensions, and materials. Our team will confirm compatibility and provide options for packaging (box, crate, or custom). We supply to manufacturers, suppliers, traders, and wholesalers, with delivery across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Filters Manufacturers - Industrial Air Filters Category

CYLINDRICAL ABS FILTER CARTRIDGE

Condition : New

Material : ABS Plastic

Cleaning Method : Other, Washable/Replaceable

Flow Rate : 10500 LPH (depends on size/model)

Pressure : Up to 5 bar

Capacity : Based on application, up to 5000 liters

Lube Oil Filters

Condition : New

Material : Stainless Steel / Mild Steel (as per model)

Cleaning Method : Other, Replaceable (nonwashable)

Flow Rate : 30 to 200 LPM (varies by model)

Pressure : Up to 15 Bar

Capacity : 9000 to 18000 Liters

CONICAL FILTER CARTRIDGE

Condition : New

Material : Stainless Steel

Cleaning Method : Other, Washable, reusable

Flow Rate : Standard and customized options available

Pressure : Up to 10 bar (customizable)

Capacity : As per design

Stainless Steel Mesh Filter Basket

Condition : New

Material : Stainless Steel

Cleaning Method : Other, Manual or Ultrasonic Cleaning

Flow Rate : 10150 L/min (varies with mesh and size)

Pressure : Up to 5 bar

Capacity : 110 Litres (based on basket dimension)

Send Inquiry

Send Inquiry