CYLINDRICAL ABS FILTER CARTRIDGE

CYLINDRICAL ABS FILTER CARTRIDGE Specification

- Filtration Grade

- Micron grade filtration (1-25 micron)

- Cleaning Method

- Washable/Replaceable

- Connecting Type

- Push fit/Threaded/Customized

- Media Type

- Synthetic fiber or non-woven polypropylene

- Temperature Range

- 5C to 60C

- Capacity

- Based on application, up to 5000 liters

- Filter Type

- Cartridge

- Flow Rate

- 10-500 LPH (depends on size/model)

- Pressure

- Up to 5 bar

- Efficiency (%)

- Up to 99%

- Condition

- New

- Material

- ABS Plastic

- Mesh

- Micro fine mesh

- Diameter

- Approx. 60-100 mm (customizable)

- Construction

- Cylindrical, seamless

- Medium Filter

- Air/Water/Oil

- Weight

- Approx. 200-400 gm

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, Corrosion resistant, Easy to install, Long service life, Uniform pore distribution

CYLINDRICAL ABS FILTER CARTRIDGE Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia, North America

- Main Domestic Market

- All India

About CYLINDRICAL ABS FILTER CARTRIDGE

CYLINDRICAL ABS FILTER CARTRIDGE

DETAILED INFORMATION ABOUT CYLINDRICAL ABS FILTER CARTRIDGE

Please contact us if you have any questions about ENVIRO TECH Air Filtration's Cylindrical ABS Filter Cartridge or our other filters.

Details

Top cap | ABS plastic | |

Gasket | EPDM | Silicone |

Inner mesh | Polypropylene PP | |

Outer mesh | Galvanized steel with hotmelt glue | Stainless steel, powder coated |

Bottom cap | ABS plastic | |

Filter media | Can be equipped with |

Customizable Filtration Solutions

Our filter cartridges can be tailored to varied requirements, including length, diameter, micron rating, and end connections. Users can select the most suitable options based on the specific applicationwhether its for water, chemical, or industrial filtration. Customization ensures optimal compatibility and performance across different environments.

High Performance and Durability

Built from corrosion-resistant ABS plastic with synthetic or non-woven media, these cartridges provide a long service life and consistent filtration efficiency. Capable of handling flow rates of 10-500 LPH and pressures up to 5 bar, they are designed to meet the demands of intensive operational environments. Their washable and replaceable nature adds to reduced maintenance time.

Versatile Application and Easy Installation

Designed for use in air, water, and oil filtration, the cartridges seamless cylindrical body supports both vertical and horizontal installation. The push-fit, threaded, or customized connections allow for hassle-free mounting and replacement, making them suitable for a diverse range of industrial and commercial applications.

FAQs of CYLINDRICAL ABS FILTER CARTRIDGE:

Q: How do I install the Cylindrical ABS Filter Cartridge?

A: Installation is straightforward due to its push-fit or threaded connections. Simply align the cartridge with the housing and secure it in place. Ensure the seal/gasket (silicone or EPDM) is properly seated for leak-free performance. The cartridge can be installed vertically or horizontally, depending on the system design.Q: What is the operating life of this filter cartridge, and how do I know when to replace it?

A: The cartridge offers an operating life of up to 12 months, depending on the filtration load, fluid properties, and application. Replacement is recommended when you observe a decline in flow rate or increased pressure drop across the filter, or at the end of its expected service interval.Q: Where can this filter cartridge be used?

A: It is suitable for water, chemical, and various industrial filtration applications. The robust ABS plastic construction, resistance to corrosion, and customizable parameters make it ideal for use in manufacturing plants, water treatment facilities, and chemical processing units.Q: What are the benefits of using this filter cartridge?

A: Key advantages include high dirt holding capacity, uniform pore distribution for efficient micron-grade filtration, resistance to corrosion, easy installation, and a long service life. It provides up to 99% filtration efficiency and supports both washable and replaceable operations for cost-effectiveness.Q: What process is followed for cleaning or replacing the cartridge?

A: If washable, remove the cartridge and rinse gently with clean water to remove accumulated debris. For replaceable cartridges, remove the old filter and insert a new one, ensuring seals are properly positioned. Regular maintenance extends operational life and ensures consistent performance.Q: How do I select the right micron rating or size for my application?

A: Determine the micron level based on the type and size of contaminants you need to remove. Finer ratings (10-25 micron) are suitable for finer particle capture, while higher ratings (up to 100 micron) target larger debris. Size and flow requirements will depend on your systems specifications and capacity needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Filters Manufacturers - Industrial Air Filters Category

CONICAL & CYLINDRICAL CARTRIDGE

Cleaning Method : Other, Washable, reusable

Filtration Grade : Other, Prefilter, fine filtration

Media Type : Other, Water, oil, chemicals, gases

Connecting Type : Other, Threaded or Flanged

Feature : High efficiency filtration, robust build, customizable size and mesh

Medium Filter : Other, Liquid, Air, Gas

CYLINDRICAL FILTER CARTRIDGE

Cleaning Method : Other, Backwash or ultrasonic cleaning

Filtration Grade : Other, Micro filtration

Media Type : Other, SS mesh, synthetic fiber optional

Connecting Type : Other, End cap with gasket seal

Feature : High dirt holding capacity, robust construction, easy installation

Medium Filter : Other, Liquids and gases

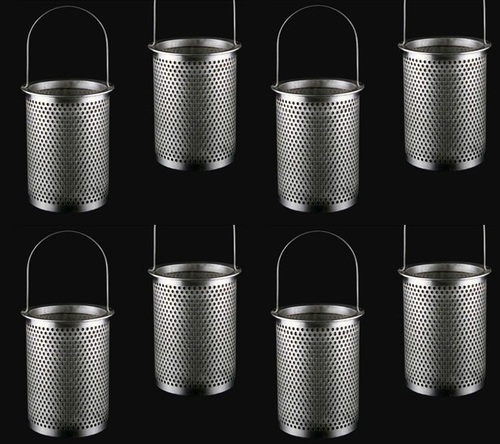

Stainless Steel Mesh Filter Basket

Cleaning Method : Other, Manual or Ultrasonic Cleaning

Filtration Grade : Other, Fine / Coarse mesh options

Media Type : Other, Water, Oil, Chemical, Air

Connecting Type : Other, Flanged, Threaded, or Slip Fit

Feature : Corrosion Resistance, High Durability, Reusable, Fine Filtration

Medium Filter : Other, Liquid/Solid Separation

SQUARE END CAP FILTER CARTRIDGE

Cleaning Method : Other, Replaceable

Filtration Grade : Other, Industrial

Media Type : Other, Synthetic Fiber / Melt Blown

Connecting Type : Other, Push Fit / Gasket Insert

Feature : High dirt holding capacity, Durable construction, Compatible with various filtration systems

Medium Filter : Other, Liquid

Send Inquiry

Send Inquiry