Series PTGB Differential Pressure Piston-Type Gage

Series PTGB Differential Pressure Piston-Type Gage Specification

- Grade

- Industrial Grade

- Seal Material

- Nitrile Rubber (NBR)

- Thread

- 1/8 NPT

- Outer Size

- 96 mm x 96 mm approx.

- Display

- Analog

- Sensor Type

- Piston-Type

- Bourdon Tube

- Not Applicable (Piston Sensing Element)

- Material

- Aluminum Body, Brass Wetted Parts

- Dial Material

- Aluminum Coated

- Pointer Material

- Black Painted Aluminum

- Processing Type

- Machined Housing

- Diameter

- 96 mm

- Glass Size

- 91 mm approx.

- Mount Type

- Panel Mount

- Scale Range

- 0-60 psi differential (various ranges available)

- Accuracy

- 2% F.S.

- Finishing

- Powder Coated / Matte Finish

- Measure Pressure Of

- Gases & Liquids (that do not attack wetted parts)

- Accessories

- Mounting Bracket, Instruction Manual

Series PTGB Differential Pressure Piston-Type Gage Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Series PTGB Differential Pressure Piston-Type Gage

Over Pressure Rating to 6000 psig, ASME Grade B 3-2-3% F.S. Accuracy

Series PTGB Differential Pressure Piston-Type Gage

Bookmark and Share

This product has been discontinued, see Series PTGD as a suggested replacement.

SpecificationsService:Compatible gases and liquids.Wetted Materials:Gage body: Aluminum or 316L SS; Piston: 316 SS; Spring: 316 SS; Ceramic Magnet; End Plugs: Aluminum (Aluminum Body), 316L SS (SS Body); Seals: Buna-N (standard).Dial Case:"Engineered Plastic" with shatter-resistant acrylic lens.Accuracy:±3-2-3% of full scale in accordance with ASME B40.100 Grade B.Pressure Limits:Working pressure 6000 psig (400 bar); Proof Pressure 12,000 psig (827 bar).Temperature Limits:-40 to 200°F (-40 to 93°C).Size:2.5" (63 mm) or 4.5" (115 mm).Mounting Orientation:Mount in any position.Process Connections:1/4" female NPT end connections standard; 1/4" female NPT back connections optional.Weight:Aluminum: 2.5": 0.60 lb (0.27 kg), 4.5": 0.95 lb (0.43 kg); 316 SS: 2.5": 1.35 lb (0.61 kg), 4.5": 1.60 lb (0.73 kg).

Durable and Reliable Differential Pressure Measurement

The PTGB Series Differential Pressure Gage is designed for industrial environments, featuring a sturdy machined aluminum body with powder-coated or matte finish. Its acrylic window and brass wetted parts provide chemical resistance for compatible gases and liquids. The analog display, paired with a high-contrast dial and precision pointer, ensures readings are easily visible and interpreted swiftly. This gage suits demanding applications such as filter monitoring and process control, consistently delivering accurate and reliable results.

User-Friendly Installation and Maintenance

Equipped with a panel mount design and a convenient mounting bracket, the PTGB gage allows for straightforward installation. The external zero adjustment screw supports ongoing accuracy without dismantling the device. Minimal maintenance is required, thanks to rugged construction and resistant materials, allowing continuous operation in challenging settings. Both the instruction manual and clear scale range facilitate quick setup and routine checks.

FAQs of Series PTGB Differential Pressure Piston-Type Gage:

Q: How does the PTGB Differential Pressure Piston-Type Gage work?

A: This gage operates using a piston-type sensing element, which moves in response to changes between upstream and downstream pressures. The displacement of the piston is mechanically linked to an analog pointer, providing a direct differential pressure reading on the scale.Q: What are the typical applications for this gage?

A: The PTGB gage is widely used in filter monitoring, flow measurement, and liquid or gas level indication within industrial settings. Its robust build and compatibility with non-aggressive gases and liquids make it well-suited for these applications.Q: When should I perform zero adjustment on the gage?

A: Zero adjustment is recommended during initial installation and periodically throughout use, especially after significant temperature shifts or mechanical impacts, to ensure measurement accuracy. The external screw makes this process simple and tool-assisted without having to open the housing.Q: Where is the connection port located on the gage?

A: The gage features a back-mounted 1/8 NPT connection, facilitating easy and secure integration into panel systems or equipment enclosures.Q: What materials are used for wetted and sealed parts?

A: Wetted parts are made from brass, while the seals are constructed of nitrile rubber (NBR). The housing itself is machined from aluminum and finished for corrosion resistance, contributing to both longevity and reliability in industrial environments.Q: How quickly does the gage respond to pressure changes?

A: It offers a rapid response time of under one second, enabling timely detection of pressure fluctuations and supporting effective process monitoring and safety.Q: What are the main benefits of using the PTGB gage?

A: Key advantages include its high accuracy (2% F.S.), rugged construction, easy installation with included bracket, straightforward maintenance, and suitability for a range of industrial applications involving compatible gases and liquids.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

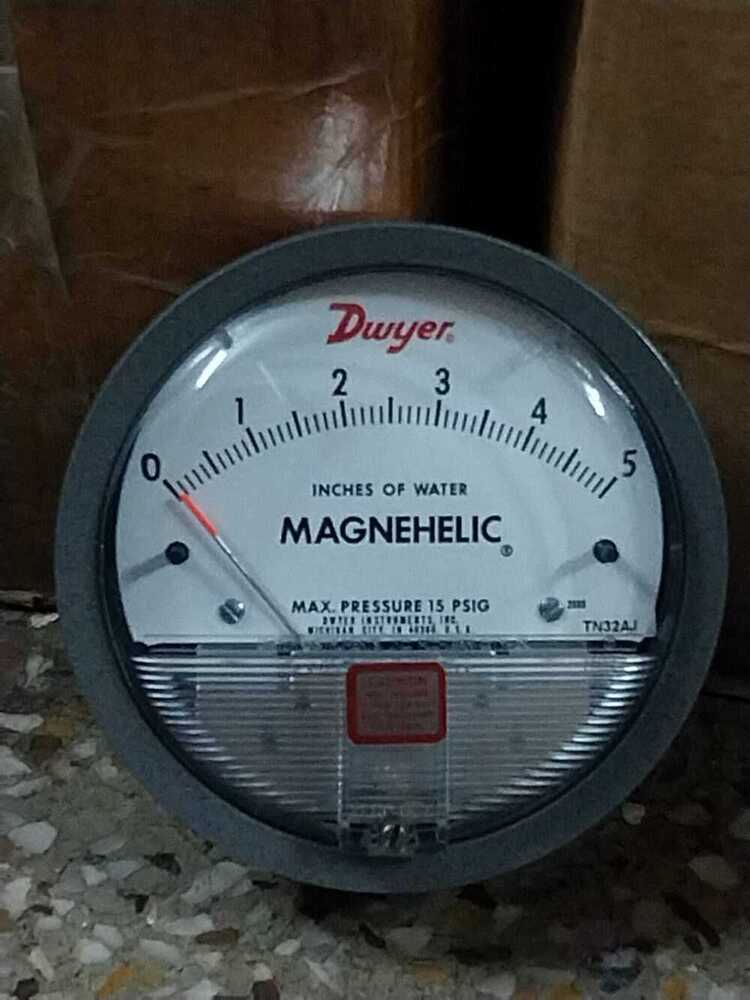

More Products in Dwyer Sensocon USA Magnehelic Gauge wholesaler Category

Dwyer Magnehelic Gauge In Beed Maharashtra

Price 5800.00 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Scale Range : MM WC/ CM / PAC / KPA / INCH

Processing Type : Standard

DWYER Magnehelic Gauge From Baikampandy Industrial Area Karnataka

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Display : Analog

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Scale Range : MM WC/ CM / PAC / KPA / INCH

Processing Type : Standard

Series PTGD Differential Pressure Piston-Type Gage

Display : Analog

Accuracy : 2% F.S.

Scale Range : 010 kg/cm or Custom Range

Processing Type : Other, Machined and Assembled

Minihelic II Differential Pressure Gauges

Display : Analog

Accuracy : 4% of full scale

Scale Range : Available in various ranges up to 30 w.c. (water column) or 75 mm w.c.

Processing Type : Other, Injection molded, precision assembly

Send Inquiry

Send Inquiry