Minihelic II Differential Pressure Gauges

Minihelic II Differential Pressure Gauges Specification

- Seal Material

- Silicone rubber

- Grade

- Industrial

- Sensor Type

- Mechanical diaphragm sensor

- Thread

- 1/8 NPT

- Bourdon Tube

- Not applicable (diaphragm type)

- Display

- Analog

- Outer Size

- About 2 inch (50 mm) diameter housing

- Material

- Polycarbonate housing, acrylic cover

- Dial Material

- White printed PVC sheet

- Pointer Material

- Molded ABS plastic

- Processing Type

- Injection molded, precision assembly

- Diameter

- 2 inches (50.8 mm)

- Glass Size

- Full view (approx. 2 inches)

- Mount Type

- Surface or panel mount

- Scale Range

- Available in various ranges up to 30 w.c. (water column) or 75 mm w.c.

- Accuracy

- 4% of full scale

- Finishing

- Matte black polycarbonate housing

- Measure Pressure Of

- Air and non-corrosive gases

- Accessories

- Mounting screws and surface mounting bracket

Minihelic II Differential Pressure Gauges Trade Information

- Main Export Market(s)

- Africa, Central America, Australia, Middle East, South America, Western Europe, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Minihelic II Differential Pressure Gauges

We have in our stores a wide assortment of Minihelic II Differential Pressure Gauges. Designed especially for panel mounting in a single 2-3/8 diameter hole, these gauges come with small size and can easily be operated up to 30 psig pressure. These gauges are manufactured by us using superior quality raw material procured by the trusted vendors of the market in accordance to international quality standards.

Features:

- Combining high accuracy

- Compactness

- Dependability

Reliable Differential Pressure Measurement

Minihelic II Differential Pressure Gauges offer precision measurement for air and non-corrosive gases, making them ideal for monitoring systems like HVAC filters and clean rooms. The mechanical diaphragm sensor ensures accurate analog readings, while the robust polycarbonate housing provides durability and long-lasting service in industrial environments.

Versatile Installation and Adjustment

Designed for ease of installation, the Minihelic II includes two side 1/8" NPT female pressure connections and supports surface or panel mounting. The external zero adjustment screw allows users to calibrate the gauge without hassle, ensuring ongoing measurement accuracy and simplicity during maintenance.

FAQs of Minihelic II Differential Pressure Gauges:

Q: How do I install the Minihelic II Differential Pressure Gauge?

A: Installation is straightforward: use the provided mounting screws and surface bracket for a secure fit. Connect two side 1/8" NPT female pressure ports to your system and ensure vertical mounting for optimal accuracy.Q: What applications are suitable for this pressure gauge?

A: Minihelic II is ideal for monitoring air and non-corrosive gases in HVAC filters, clean rooms, and environmental chambers. Its industrial-grade design meets requirements for reliable measurement in demanding environments.Q: When should I use the zero adjustment feature?

A: Utilize the external zero adjustment screw before initial use or after relocation to ensure the gauge reads accurately at rest. Regular calibration maintains precise measurements over time.Q: Where is the Minihelic II manufactured and supplied?

A: This gauge conforms to the Dwyer Minihelic II design and is manufactured, supplied, traded, and wholesaled by authorized dealers throughout India.Q: What is the maximum safe pressure for operation?

A: The Minihelic II can safely handle overpressure up to 25 psig (1.7 bar). Exceeding this limit may damage the gauge or compromise measurement accuracy.Q: How does the mechanical diaphragm sensor benefit the gauges performance?

A: The diaphragm sensor provides responsive and stable analog readings for low-pressure differentials, ensuring accuracy within 4% of full scale and reliable operation across various applications.Q: What are the key advantages of the materials used in the Minihelic II?

A: Its polycarbonate housing and acrylic window offer impact resistance and clarity, while silicone rubber seals and precision assembly enhance durability and measurement reliability in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

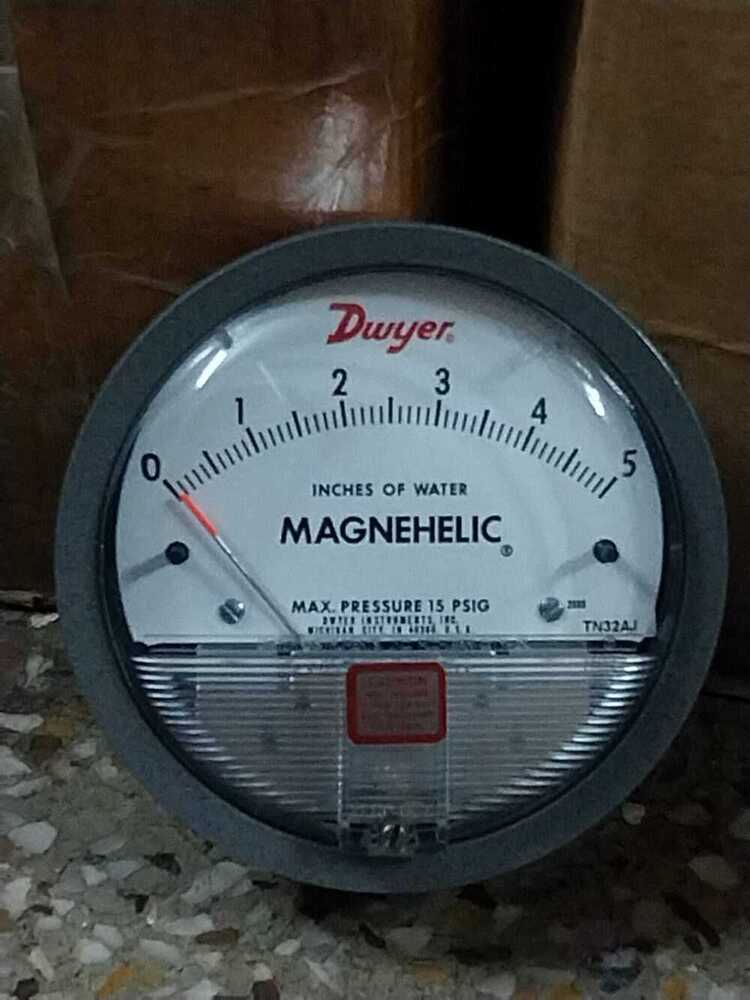

More Products in Dwyer Sensocon USA Magnehelic Gauge wholesaler Category

DWYER Magnehelic Gauge From Karnad Industrial Area Karnataka

Price 7500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pointer Material : Alloy

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Material : Metal Alloy

Display : Analog

Dwyer Magnehelic Gauge In Beed Maharashtra

Price 5800.00 INR / Piece

Minimum Order Quantity : 1 Piece

Pointer Material : Alloy

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Material : Metal Alloy

Display : Analog

DWYER Magnehelic Gauge From Yeyyadi Industrial Area Karnataka

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Pointer Material : Alloy

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Material : Metal Alloy

Display : Analog

Series PTGD Differential Pressure Piston-Type Gage

Pointer Material : Other, Black Anodized Aluminum

Accuracy : 2% F.S.

Material : Other, Stainless Steel Body, Brass Wetted Parts

Display : Analog

Send Inquiry

Send Inquiry