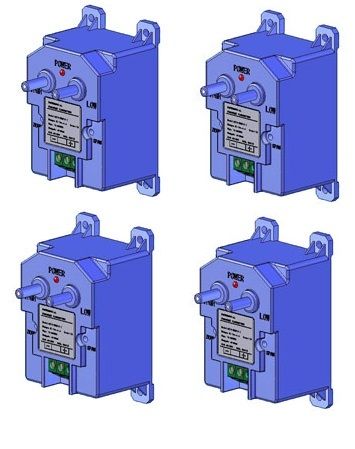

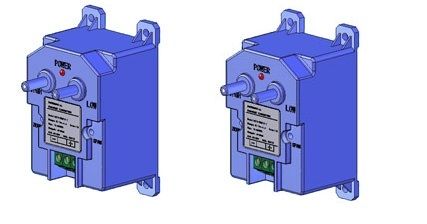

Sensocon USA SERIES 211-D020I-3 Differential Pressure Transmitter

Sensocon USA SERIES 211-D020I-3 Differential Pressure Transmitter Specification

- Thread

- 1/8 NPT Female

- Sensor Type

- Differential Pressure Transmitter

- Outer Size

- 126 x 113 x 60 mm approx.

- Display

- Digital LCD

- Seal Material

- Silicone

- Grade

- Industrial

- Material

- ABS Plastic Enclosure

- Processing Type

- Electronic

- Mount Type

- Panel/Surface Mount

- Scale Range

- 0-20 W.C. (Inches of Water Column)

- Accuracy

- 1% of Full Scale

- Finishing

- Textured Enclosure

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting Screws, Instruction Manual

Sensocon USA SERIES 211-D020I-3 Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, South America, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India

About Sensocon USA SERIES 211-D020I-3 Differential Pressure Transmitter

Sensocon USA SERIES 211-D020I-3 Differential Pressure Transmitter

- Model 211-D020I-3

- Pressure Range 0-20

- Accuracy 0.25%

- Compact Design

- 0.25% Accuracy

- LED Power Indication

- 4 20 mA or 0 10 V output

The Series 211 Differential Pressure Transmitter can accurately measure positive, negative, or differential pressure and send the corresponding 4 20 mA output signal. The Series 211 Differential Pressure Transmitter is not position sensitive and can be mounted in any orientation without compromising accuracy. It also features a power LED, so you always know when the transmitter is operating. The compact, lightweight design makes installation simple and easy.

SPECIFICATIONS

- Maximum Pressure:Ranges 5 PSI (35 kPa) = 15 PSI (100 kPa) Max Ranges > 5 PSI (35 kPa) = 30 PSI (200 kPa) Max

- Media Compatibility:Air and compatible noncombustible, non-corrosive gasses

- Accuracy:Ranges 4 w.c. (1 kPa) 1.0% Ranges 5 w.c. (1.25 kPa) 0.25%

- Temperature Ranges:Compensated: 15 to 120F (-10 to 50C) Operating: -10 to 155F (-25 to 70C)

- Thermal Effect:+/- 0.028% FS/F (+/- 0.050%/C)

- Stability: +/- 0.25% FS/year

- Output Signal: 4-20 mA, 2 wire or 0-10V

- Loop Resistance: 250 @ 24 VDC

- Power Supply: 12-30 VDC

- Housing Material: ABS Plastic

- Electrical Connections: screw terminals

- Process Connection: Push on connection for 3/16 I.D. tubing

- Agency Approvals: CE

Precision Measurement for Industrial Applications

Engineered for versatility, the SERIES 211-D020I-3 transmitter delivers reliable pressure measurements for air and non-corrosive gases across a 0-20 W.C. range. With its digital LCD display and electronic processing, users can easily monitor real-time pressure values, ensuring highly accurate readings in demanding industrial surroundings.

User-Friendly Calibration and Installation

Effortless maintenance and setup are hallmarks of the SERIES 211-D020I-3. The transmitter features convenient push button zero and span adjustment, allowing users to calibrate the device without specialized equipment. Installation is straightforward thanks to included mounting screws, clear instructions, and a compact 2-wire connection for power and output.

FAQs of Sensocon USA SERIES 211-D020I-3 Differential Pressure Transmitter:

Q: How do I calibrate the SERIES 211-D020I-3 Differential Pressure Transmitter?

A: Calibration is performed using the integrated push button zero and span adjustment on the transmitters front panel. This allows for simple, precise setting without the need for external tools, ensuring the device maintains accuracy over its 1% full-scale range.Q: What environments are suitable for installing this pressure transmitter?

A: The device is rated IP54, making it suitable for industrial environments with protection against limited dust ingress and water splashes. It should be installed where the ambient temperature remains between 0 to 60C, ensuring optimal performance and longevity.Q: When should the transmitter be used for air and non-corrosive gas measurement?

A: The SERIES 211-D020I-3 is ideal for continuous, precise differential pressure monitoring in HVAC systems, cleanrooms, or industrial process control, especially when air or non-corrosive gases are involved and a digital output is required.Q: Where is the transmitter typically mounted for best results?

A: For optimal accessibility and measurement accuracy, the transmitter can be mounted either on a panel or a surface using the provided mounting screws. The compact design (126 x 113 x 60 mm) allows flexibility in installation locations within industrial settings.Q: What benefits does the digital LCD display provide?

A: The digital LCD display offers instant, clear pressure readings, which simplifies monitoring, troubleshooting, and maintenance. Users can quickly assess system status without additional instrumentation, enhancing operational efficiency.Q: How is the transmitter connected electrically and what is the required power supply?

A: The transmitter utilizes a 2-wire connection design for both the power (12-36 VDC) and 4-20 mA output signal, streamlining installation and compatibility with standard industrial control systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon 211 Differential Pressure Transmitter Category

Sensocon USA SERIES 211-D010I-3 Differential Pressure Transmitter

Grade : Industrial

Material : Other, ABS/Polycarbonate Housing

Processing Type : Other, Electronic

Seal Material : BunaN

Measure Pressure Of : Other, Air and Noncorrosive Gases

Accessories : Mounting Hardware Included

Sensocon USA SERIES 211-D500A-1 Differential Pressure Transmitter

Grade : Industrial

Material : Other, Anodized Aluminum Housing

Processing Type : Other, Microprocessor Controlled

Seal Material : BunaN Rubber

Measure Pressure Of : Other, Air and Noncorrosive Gases

Accessories : Mounting Bracket, Installation Manual

Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter

Grade : Industrial Grade

Material : Other, Polycarbonate, ABS, Aluminum

Processing Type : Other, Digital Signal Processing

Seal Material : EPDM Rubber

Measure Pressure Of : Other, Air and NonCorrosive Gases

Accessories : Mounting Kit Included

Sensocon USA SERIES 211-D010P-3 Differential Pressure Transmitter

Grade : Industrial Grade

Material : Other, ABS Plastic / Electronic Components

Processing Type : Other, Digital

Seal Material : BunaN

Measure Pressure Of : Other, Air and NonCorrosive Gases

Accessories : Mounting Bracket, Instruction Manual

Send Inquiry

Send Inquiry