Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter

Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter Specification

- Outer Size

- 4.5 inches (115 mm) Diameter

- Grade

- Industrial Grade

- Seal Material

- EPDM Rubber

- Sensor Type

- Differential Pressure Sensor

- Thread

- 1/8 NPT Female

- Display

- Digital LCD

- Material

- Polycarbonate, ABS, Aluminum

- Processing Type

- Digital Signal Processing

- Diameter

- 4.5 inches

- Mount Type

- Surface/Wall Mount

- Scale Range

- 0-3.00 kPa (0-12 inH2O)

- Accuracy

- 1% of Full Scale

- Finishing

- Anodized Aluminum Housing

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting Kit Included

Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter

Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter

- Model 211-D003K-3

- Pressure Range 0-3 Kpa

- Accuracy 0.25%

- Compact Design

- 0.25% Accuracy

- LED Power Indication

- 4 20 mA or 0 10 V output

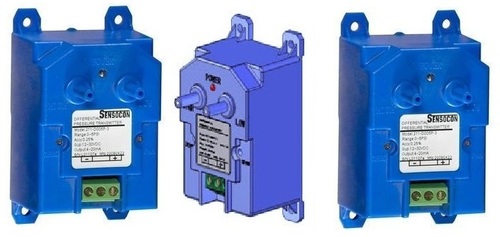

The Series 211 Differential Pressure Transmitter can accurately measure positive, negative, or differential pressure and send the corresponding 4 20 mA output signal. The Series 211 Differential Pressure Transmitter is not position sensitive and can be mounted in any orientation without compromising accuracy. It also features a power LED, so you always know when the transmitter is operating. The compact, lightweight design makes installation simple and easy.

SPECIFICATIONS

- Maximum Pressure:

- Ranges 5 PSI (35 kPa) = 15 PSI (100 kPa) Max Ranges > 5 PSI (35 kPa) = 30 PSI (200 kPa) Max

- Media Compatibility:

- Air and compatible noncombustible, non-corrosive gasses

- Accuracy:

- Ranges 4 w.c. (1 kPa) 1.0% Ranges 5 w.c. (1.25 kPa) 0.25%

- Temperature Ranges:

- Compensated: 15 to 120F (-10 to 50C) Operating: -10 to 155F (-25 to 70C)

- Thermal Effect:+/- 0.028% FS/F (+/- 0.050%/C)

- Stability: +/- 0.25% FS/year

- Output Signal: 4-20 mA, 2 wire or 0-10V

- Loop Resistance: 250 @ 24 VDC

- Power Supply: 12-30 VDC

- Housing Material: ABS Plastic

- Electrical Connections: screw terminals

- Process Connection: Push on connection for 3/16 I.D. tubing

- Agency Approvals: CE

High Performance for Industrial Applications

Engineered for precision and durability, the SERIES 211-D003K-3 caters to the needs of industrial-grade measurements. The transmitters digital signal processing ensures accurate readings within 1% of full scale, while the front-accessible zero and span adjustment facilitate hassle-free calibration in the field. Its sturdy anodized aluminum housing and IP54 ingress protection make it suitable for demanding environments.

User-Friendly Installation and Operation

Installation is straightforward with a surface/wall mount design, a provided mounting kit, and a screw terminal block for secure electrical connections. The transmitter uses dual 1/8 NPT female threaded ports for high and low pressure input. Its clear digital LCD display allows users to easily monitor pressure levels during operation, providing reliability and convenience for routine checks.

FAQs of Sensocon USA SERIES 211-D003K-3 Differential Pressure Transmitter:

Q: How do I install the Sensocon SERIES 211-D003K-3 differential pressure transmitter?

A: The transmitter is designed for easy surface or wall mounting using the included mounting kit. Simply attach the device using the mounting bracket, connect the wiring to the screw terminal block, and secure the high and low pressure lines to the dual 1/8 NPT female ports.Q: What type of media can be measured with this differential pressure sensor?

A: The SERIES 211-D003K-3 is suitable for measuring air and non-corrosive gases only. It is not recommended for use with corrosive or liquid media, ensuring a long service life when deployed in HVAC, cleanroom, and industrial process applications.Q: When should I perform zero and span adjustments and how can I access them?

A: Zero and span adjustments should be performed during initial setup or periodic calibration checks to maintain measurement accuracy. These adjustments are conveniently accessible at the front of the unit, enabling easy calibration without the need to dismount the transmitter.Q: What benefits does the digital LCD display offer?

A: The digital LCD display provides immediate and accurate pressure readings at a glance, enabling operators to monitor system performance in real time and reduce the risk of errors during operation or maintenance.Q: Where is the Sensocon SERIES 211-D003K-3 commonly used?

A: This differential pressure transmitter is widely used in India across HVAC systems, cleanrooms, filter monitoring, and process industries, especially where precise measurement of low differential pressures in air and non-corrosive gases is critical.Q: What is the process for connecting the electrical wiring?

A: The electrical connections are made via a screw terminal block, ensuring secure and reliable wiring. Use a 12-36 VDC power supply and connect the output through the 4-20 mA (2-wire) interface as per the device wiring instructions outlined in the user manual.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon 211 Differential Pressure Transmitter Category

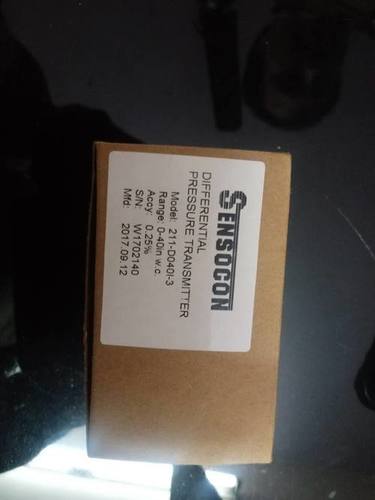

Sensocon USA SERIES 211-D040I-3 Differential Pressure Transmitter

Accessories : Mounting Kit, Manual

Sensor Type : Differential Pressure Transmitter

Measure Pressure Of : Other, Air and NonCorrosive Gases

Scale Range : 040 WC (Water Column)

Seal Material : Silicone Rubber

Outer Size : 124 mm x 70 mm x 55 mm (approx)

Sensocon USA SERIES 211-D015P-3 Differential Pressure Transmitter

Accessories : Mounting Screws, User Manual

Sensor Type : Piezo Resistive

Measure Pressure Of : Other, Air & Noncombustible Gases

Scale Range : 00.15 PSI

Seal Material : EPDM

Outer Size : 93 mm x 93 mm x 61 mm (Approx)

Sensocon USA SERIES 211-D001K-1 Differential Pressure Transmitter

Accessories : Mounting Hardware, Instruction Manual

Sensor Type : Differential Pressure Transmitter

Measure Pressure Of : Other, Air and Noncorrosive Gases

Scale Range : 01.0 kPa

Seal Material : EPDM Rubber

Outer Size : 110 mm x 89 mm x 62 mm (approx.)

Sensocon USA SERIES 211-D006I-3 Differential Pressure Transmitter

Accessories : Mounting hardware, User Manual

Sensor Type : Differential Pressure Sensor

Measure Pressure Of : Other, Air and Noncorrosive Gases

Scale Range : 06 WC (Water Column)

Seal Material : Silicone / BunaN

Outer Size : 125 x 80 x 55 mm (Approx.)

Send Inquiry

Send Inquiry