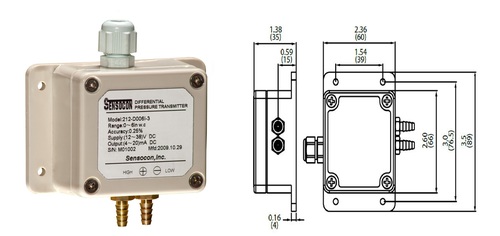

Sensocon USA 212-D025K-3 Differential Pressure Transmitter

Sensocon USA 212-D025K-3 Differential Pressure Transmitter Specification

- Outer Size

- 118 mm x 118 mm x 59 mm (Approx.)

- Seal Material

- EPDM Rubber

- Thread

- 1/8 NPT Female

- Grade

- Industrial Grade

- Display

- Digital

- Sensor Type

- Differential Pressure Transmitter

- Material

- Polycarbonate Housing

- Processing Type

- Electronic

- Diameter

- 118 mm (Front Face Diameter)

- Mount Type

- Wall Mount

- Scale Range

- 0 - 25000 Pa (0 - 25 kPa)

- Accuracy

- 1% of Full Scale

- Finishing

- Powder Coated / Matte Finish

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Kit Included

Sensocon USA 212-D025K-3 Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Sensocon USA 212-D025K-3 Differential Pressure Transmitter

Sensocon USA SERIES 212-D025K-3 Differential Pressure Transmitter- Model 212-D0025K-3

- Pressure Range 0-25 Kpa

- Accuracy 0.25%

- Compact Design

- 0.25% Accuracy

- LED Power Indication

- 4 20 mA or 0 10 V output

SPECIFICATIONS

- Maximum Pressure:

- Ranges 5 PSI (35 kPa) = 15 PSI (100 kPa) Max Ranges > 5 PSI (35 kPa) = 30 PSI (200 kPa) Max

- Media Compatibility:

- Air and compatible non combustible, non-corrosive gasses

- Accuracy:

- Ranges 4 w.c. (1 kPa) 1.0% Ranges 5 w.c. (1.25 kPa) 0.25%

- Temperature Ranges:

- Compensated: 15 to 120F (-10 to 50C) Operating: -10 to 155F (-25 to 70C)

- Thermal Effect:+/- 0.028% FS/F (+/- 0.050%/C)

- Stability: +/- 0.25% FS/year

- Output Signal: 4-20 mA, 2 wire or 0-10V

- Loop Resistance: 250 @ 24 VDC

- Power Supply: 12-30 VDC

- Housing Material: ABS Plastic

- Electrical Connections: screw terminals

- Process Connection: Push on connection for 3/16 I.D. tubing

- Agency Approvals: CE

Reliable Differential Pressure Measurement

Designed for demanding industrial environments, the Sensocon 212-D025K-3 provides accurate and consistent monitoring of differential air and non-corrosive gas pressures. Its broad measuring range up to 25,000 Pa and 1% accuracy make it ideal for HVAC, filtration, and cleanroom applications, while the IP65 enclosure ensures longevity in challenging settings.

User-Friendly Installation and Interface

Equipped with a clear digital display and a mounting kit, this transmitter facilitates effortless on-site installation and easy readability. The 1/8" NPT female threads allow for secure connections, and the transmitters compact design supports flexible placement in various setups, suiting maintenance and space requirements.

FAQs of Sensocon USA 212-D025K-3 Differential Pressure Transmitter:

Q: How is the Sensocon 212-D025K-3 differential pressure transmitter installed?

A: This transmitter is designed for wall mounting and comes with a mounting kit for straightforward installation. Simply connect the two 1/8" NPT female pressure ports to your air or non-corrosive gas lines and use the included hardware to fix the device securely to the wall.Q: What are the primary applications for this differential pressure transmitter?

A: The 212-D025K-3 is ideal for monitoring differential pressures in HVAC systems, cleanrooms, filtration units, and industrial process controls, particularly where precise air or non-corrosive gas measurements are required.Q: When should I use this model instead of a standard pressure transmitter?

A: This model is specifically designed for situations where monitoring the pressure difference between two points is necessary, such as in air flow measurement, filter monitoring, or pressurized room control. If your application requires accuracy across a large range or robust environmental protection, this model is an excellent choice.Q: Where can the Sensocon 212-D025K-3 be mounted?

A: Thanks to its wall-mount design and IP65-rated protection, the transmitter can be installed indoors or in protected outdoor industrial settings, provided it is not exposed directly to corrosive chemicals or extreme weather conditions.Q: What are the benefits of the digital display and rapid response time?

A: The integrated digital display provides instant pressure readings on site, eliminating manual gauge checks. With a response time below 500 ms, the transmitter quickly detects pressure changes, supporting accurate and real-time system adjustments.Q: How does the transmitter ensure safety and reliability?

A: With its industrial-grade polycarbonate housing, powder-coated finish, EPDM rubber seals, and IP65 protection, the device is engineered to resist dust, moisture, and moderate impacts. This ensures reliable operation even in tough environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 212 Weather Proof Differential Pressur Transmitter Category

Sensocon USA 212-D001I-1 Differential Pressure Transmitter

Finishing : Other, Powder Coated

Accuracy : 1% of full scale

Measure Pressure Of : Other, Air and compatible gases

Accessories : Mounting Screws, Instruction Manual

Outer Size : 103 mm x 80 mm x 45 mm

Seal Material : EPDM

Sensocon USA 212-D050K-3 Differential Pressure Transmitter

Finishing : Other, Powder Coated

Accuracy : 1.0% FS

Measure Pressure Of : Other, Air & Noncorrosive gases

Accessories : Mounting Bracket, Installation Manual

Outer Size : 104 mm x 75 mm x 40 mm (W x H x D)

Seal Material : Silicone

Sensocon USA 212-D040I-3 Differential Pressure Transmitter

Finishing : Other, Textured Black Enclosure

Accuracy : 1% FS

Measure Pressure Of : Other, Air and Compatible Gases

Accessories : Mounting Hardware

Outer Size : 4.43 x 2.06 x 5.88 (L x W x H)

Seal Material : EPDM

Sensocon USA 212-D004I-1 Differential Pressure Transmitter

Finishing : Other, Powdercoated aluminium housing

Accuracy : 1% of span

Measure Pressure Of : Other, Air and noncorrosive gases

Accessories : Mounting screws, Installation manual

Outer Size : 120 mm x 80 mm x 57 mm (approximate)

Seal Material : Silicone

Send Inquiry

Send Inquiry