Sensocon USA 212-D020I-3 Differential Pressure Transmitter

Sensocon USA 212-D020I-3 Differential Pressure Transmitter Specification

- Sensor Type

- Differential Pressure Transmitter

- Seal Material

- NBR (Nitrile Rubber)

- Thread

- 1/8 NPT Female

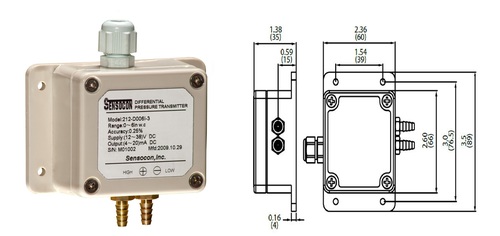

- Outer Size

- Approximately 126 x 118 x 60 mm

- Display

- Digital LCD

- Grade

- Industrial

- Material

- ABS Plastic Enclosure

- Processing Type

- Electronic

- Mount Type

- Panel or Wall Mount

- Scale Range

- 0-20 inches of water column (inWC)

- Accuracy

- 1% of Full Scale

- Finishing

- Powder Coated

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Hardware Included

Sensocon USA 212-D020I-3 Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

About Sensocon USA 212-D020I-3 Differential Pressure Transmitter

Sensocon USA SERIES 212-D020I-3 Differential Pressure Transmitter- Model 212-D020I-3

- Pressure Range 0-20

- Accuracy 0.25%

- Compact Design

- 0.25% Accuracy

- LED Power Indication

- 4 20 mA or 0 10 V output

SPECIFICATIONS

- Maximum Pressure:Ranges : 5 PSI (35 kPa) = 15 PSI (100 kPa) Max Ranges > 5 PSI (35 kPa) = 30 PSI (200 kPa) Max

- Media Compatibility:Air and compatible noncombustible, non-corrosive gasses

- Accuracy:Ranges : 4 w.c. (1 kPa) 1.0% Ranges : 5 w.c. (1.25 kPa) 0.25%

- Temperature Ranges:Compensated: 15° to 120°F (-10° to 50°C) Operating: -10° to 155°F (-25° to 70°C)

- Thermal Effect:+/- 0.028% FS/°F (+/- 0.050%/°C)

- Stability: +/- 0.25% FS/year

- Output Signal: 4-20 mA, 2 wire or 0-10V

- Loop Resistance: 250 - 24 VDC

- Power Supply: 12-30 VDC

- Housing Material: ABS Plastic

- Electrical Connections: screw terminals

- Process Connection: Push on connection for 3/16 I.D. tubing

- Agency Approvals: CE

Rugged and Versatile Industrial Design

Built with a powder-coated ABS enclosure and NEMA 4X (IP65) protection, the 212-D020I-3 stands up to demanding conditions. Its industrial-grade design assures reliability and adaptability, making it ideal for manufacturing, clean rooms, HVAC, and process control environments requiring accurate air or non-corrosive gas pressure monitoring.

Precision Measurement with User-Friendly Operation

The differential pressure transmitter offers a scale of 020 inWC, with 1% full-scale accuracy. Easy push-button zero/span adjustment streamlines calibration. Featuring a bright digital LCD display, users can conveniently monitor real-time pressure readings, ensuring optimal performance and process efficiency in dynamic settings.

FAQs of Sensocon USA 212-D020I-3 Differential Pressure Transmitter:

Q: How do I install the Sensocon USA 212-D020I-3 Differential Pressure Transmitter?

A: The transmitter can be mounted either on a panel or wall using the included mounting hardware. Electrical connections are made via the removable terminal block, and pressure ports accept 1/8 NPT female fittings. Ensure compatibility with dry, clean, non-corrosive gases during installation.Q: What types of media can this transmitter measure?

A: The 212-D020I-3 is designed to measure differential pressure in dry, clean, and non-corrosive gasessuch as airmaking it suitable for HVAC, clean room, and similar industrial applications. It is not intended for use with liquids or corrosive gases.Q: When should zero and span adjustments be performed?

A: Zero and span adjustments are recommended upon initial installation, after maintenance, or if calibration drift is suspected. The push button interface simplifies these adjustments for optimal accuracy.Q: Where are the devices electrical connections located and how are they accessed?

A: Electrical connections are made through a removable terminal block located within the enclosure. The NEMA 4X (IP65) enclosure is easily opened for wiring, ensuring quick and secure connectivity.Q: What benefits does the digital LCD display offer to users?

A: The integrated digital LCD display provides instantaneous and clear pressure readings. This allows for real-time monitoring, fast diagnostics, and simplified setup, contributing to system reliability and safety.Q: How does the fast response time of less than 100 milliseconds impact process control?

A: A rapid response time delivers near-instantaneous updates of pressure changes, enhancing control accuracy and responsiveness for critical applications, reducing delays and improving process stability.Q: What are the advantages of the NEMA 4X (IP65) enclosure rating for this transmitter?

A: The NEMA 4X (IP65) rating ensures the transmitter is dust-tight and resistant to water jets, making it suitable for harsh industrial environments, promoting durability and long service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 212 Weather Proof Differential Pressur Transmitter Category

Series 212 Weather-Proof Differential Pressure Transmitter

Measure Pressure Of : Other, Air and NonCorrosive Gases

Accessories : Mounting Bracket, Calibration Certificate

Seal Material : Nitrile Rubber

Sensor Type : Capacitive Differential Pressure Sensor

Thread : G1/2 BSP

Accuracy : 1% of Full Scale

Sensocon USA 212-D001I-1 Differential Pressure Transmitter

Measure Pressure Of : Other, Air and compatible gases

Accessories : Mounting Screws, Instruction Manual

Seal Material : EPDM

Sensor Type : Differential Pressure Transmitter

Thread : 1/8 NPT Female

Accuracy : 1% of full scale

Sensocon USA 212-D040I-3 Differential Pressure Transmitter

Measure Pressure Of : Other, Air and Compatible Gases

Accessories : Mounting Hardware

Seal Material : EPDM

Sensor Type : Differential Pressure Transmitter

Thread : 1/8 NPT Female

Accuracy : 1% FS

Sensocon USA 212-D025K-3 Differential Pressure Transmitter

Measure Pressure Of : Other, Air and Noncorrosive Gases

Accessories : Mounting Kit Included

Seal Material : EPDM Rubber

Sensor Type : Differential Pressure Transmitter

Thread : 1/8 NPT Female

Accuracy : 1% of Full Scale

Send Inquiry

Send Inquiry