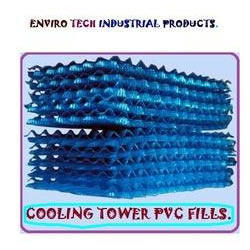

pvc- fills

pvc- fills Specification

- Material

- Rigid PVC

- Application

- Cooling Towers, Industrial Water Cooling

- Condition

- New

- Type

- PVC Fills / Fill Media

- Dimension (L*W*H)

- 1200 mm x 600 mm x 150 mm (Common size, customizable)

- Cooling Type

- Evaporative

- Water Flowing Rate

- Depends on cooling tower design

- Noise Control

- Improved by optimized fill design

About pvc- fills

Owing to the immense experience and a competent team of experts, we are able to offer PVC Fills to respectable clients. These PVC fills offered by us are made utilizing high grade raw material, which is sourced from trustworthy vendors of the market. In addition to this, the offered range of PVC fills is applicable in humidification, effluent treatment, power, petrochemical, refining, paper chemical, steel and allied industries. This PVC Cooling Tower Fills is known for distributing the liquid and gas across the many interconnected channels within the surface material. For inducing highly turbulent mixing between the water and the air, which increases heat and moisture transfer, cross fluted designs is introduced.

Features:

- Light weight

- Fire safe

- Decay proof

- Mass transfer & heat transfer coefficient

- Low pressure drop

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Enhanced Cooling Efficiency

Designed using a precise honeycomb corrugated structure, our PVC fills maximize contact between water and air, improving evaporative cooling efficiency in both cross flow and counter flow towers. The carefully engineered gap between sheets (12 mm to 19 mm) and optimal packing density (120 - 160 m/m) ensure high thermal performance and noise reduction.

Durable and Customizable Solutions

Made from rigid PVC, these fills are built for long-term usage, with their service life depending largely on water quality and regular maintenance. They come in standard and customizable dimensions to suit various cooling tower designs and are available with optional flame retardant properties. Their material and construction ensure easy cleaning and hassle-free refitting.

FAQs of pvc- fills:

Q: How should PVC fills be cleaned and maintained for optimal performance?

A: PVC fills can be easily removed from the cooling tower, gently washed with clean water, and refitted. Periodic cleaning helps maintain efficiency and prolongs service life, especially in sectors where water quality may lead to scaling or biological growth.Q: What configurations of cooling towers are supported by these PVC fills?

A: These fills are designed to support both cross flow and counter flow cooling towers, making them suitable for a wide range of industrial cooling applications.Q: When is flame retardant capability needed for PVC fill media?

A: Flame retardant PVC fills are recommended in applications where enhanced fire safety is required, such as in facilities with strict regulatory standards or heightened risk of fire hazards. This feature is available upon request prior to manufacturing.Q: Where can these PVC fills be installed?

A: PVC fills can be installed in industrial water cooling systems, specifically in cooling towers at manufacturing plants, power stations, or any industrial setup requiring efficient heat dissipation. Their adaptable design allows installation across different tower types.Q: What are the benefits of honeycomb corrugated PVC fills in cooling towers?

A: The honeycomb corrugated structure increases the surface area for water and air contact, resulting in improved heat exchange, reduced operational noise, and enhanced cooling efficiency. This structure also supports easy water flow and helps in noise control.Q: How does the thickness and gap between sheets affect the cooling process?

A: The sheet thickness (0.25 mm to 0.40 mm) and gap (12 mm to 19 mm) are optimized to promote efficient water distribution, air passage, and heat transfer while minimizing pressure drop. This results in reliable and sustained cooling performance.Q: What is the typical service life of these PVC fills, and what factors influence it?

A: The service life of PVC fills is long but largely depends on water quality and regular maintenance. Hard or contaminated water can reduce longevity, so periodic cleaning and proper water treatment are recommended for best performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Cooling Tower Accessories Manufacturer India Category

Pvc Cooling Tower Accessories

Material : Other , High Quality PVC (Polyvinyl Chloride)

Application : Cooling Tower Water Distribution, Heat Exchange Enhancement

Type : Cooling Tower Accessories

Cooling Type : Water Cooling

Dimension (L*W*H) : Variable Available in standard and custom sizes

Condition : New

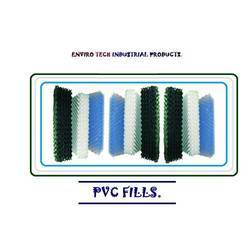

honeycomb- pvc -fills

Material : Other , Rigid Polyvinyl Chloride (PVC)

Application : Cooling Towers, Industrial Cooling Systems, HVAC

Type : Honeycomb PVC Fill

Cooling Type : Evaporative Cooling

Dimension (L*W*H) : 600mm x 300mm x 150mm (customizable)

Condition : New

sigma-type- pvc-fill

Material : Other , PVC (Polyvinyl Chloride)

Application : Cooling Tower / Industrial Water Cooling

Type : Sigma Type PVC Fill

Cooling Type : Water Cooling

Dimension (L*W*H) : 600 mm x 300 mm x 150 mm, or customized

Condition : New

cooling- tower-pvc-fill

Material : Other , PVC (Polyvinyl Chloride)

Application : Cooling Towers, Water Cooling Systems

Type : Honeycomb PVC Fill

Cooling Type : Wet Cooling

Dimension (L*W*H) : 600 mm x 300 mm x 150 mm (Typical)

Condition : New

Send Inquiry

Send Inquiry