honeycomb- pvc -fills

honeycomb- pvc -fills Specification

- Application

- Cooling Towers, Industrial Cooling Systems, HVAC

- Material

- Rigid Polyvinyl Chloride (PVC)

- Condition

- New

- Type

- Honeycomb PVC Fill

- Dimension (L*W*H)

- 600mm x 300mm x 150mm (customizable)

- Cooling Type

- Evaporative Cooling

- Water Flowing Rate

- Supported rate: Up to 4 m3/hr per m2

- Noise Control

- Low Noise Operations

About honeycomb- pvc -fills

We are a trusted name engaged in manufacturing a comprehensive range of Honeycomb P.V.C. Fills which are continuously vacuum formed. These are superior in quality in terms of durability, user-friendliness and maintenance. Some essentials features are:

- These are specially treated to offer maximum contact area for heat exchange.

- In it, the crossing of air and water streams is in close proximity

- The proximity creates a diffused turbulence which is conducive to evaporation and efficient heat transfer.

Features

- Rigid Poly Vinyl chloride (PVC)

- Honey comb design with double edge folded very large contact surface area

- Fills Flute height 12mm to 19mm & sheet thick 0.2 to 0.25 mm

- Fill Size : 600mm x 300mm x 150mm

- Color : Blue, Black, White.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Engineered for Efficient Cooling

Our Honeycomb PVC Fills deliver superior performance for cooling towers and industrial HVAC systems. The honeycomb structure maximizes contact area, promoting efficient evaporative cooling and consistent water flow. Designed to resist clogging, they ensure low-maintenance operation and reliable cooling year-round.

Robust Material and Custom Fit

Crafted from rigid polyvinyl chloride, the fills maintain structural integrity up to 60C and are available in standard or custom sizes to match unique project requirements. Flame retardant variants are available on request. Their lightweight build enables easy on-site handling and swift installation or replacement.

Low Noise Operation and Long Lifespan

Benefit from noise-reducing design, making them ideal for environments where acoustic comfort matters. With a lifespan of 5 to 8 years under standard operating conditions, these PVC fills offer cost-effective durability for a range of cooling applications.

FAQs of honeycomb- pvc -fills:

Q: How are honeycomb PVC fills installed in cooling towers?

A: Honeycomb PVC fills are designed for easy installation and replacement. Their modular structure and lightweight build allow technicians to quickly place or swap the fills within cross flow or counterflow cooling towers, minimizing system downtime.Q: What makes the honeycomb structure beneficial for cooling performance?

A: The honeycomb configuration increases the surface area for heat and water exchange, optimizing evaporative cooling efficiency and enabling even water distribution. This structure also supports high clogging resistance, ensuring prolonged system effectiveness.Q: When should I opt for the flame retardant version of PVC fills?

A: Flame retardant honeycomb PVC fills are recommended for installations where fire safety is a priority, such as in industrial facilities with strict compliance requirements. These can be requested at the time of order to suit specific operational standards.Q: Where can these honeycomb PVC fills be used?

A: These fills are suitable for both cross flow and counterflow cooling towers, industrial cooling systems, and HVAC units. They perform reliably in various settings, from manufacturing facilities to commercial buildings, throughout India.Q: What process is involved in customizing fill dimensions or density?

A: Custom orders can be processed by specifying the required dimensions and density at the time of purchase. The manufacturer accommodates project-specific needs, ensuring the fills integrate seamlessly into existing or new cooling tower configurations.Q: What advantages does high clogging resistance provide in operation?

A: A high clogging resistance means reduced maintenance, longer intervals between servicing, and sustained cooling performance even in environments with challenging water quality. This helps minimize downtime and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Cooling Tower Accessories Manufacturer India Category

Pvc Cooling Tower Accessories

Material : Other , High Quality PVC (Polyvinyl Chloride)

Application : Cooling Tower Water Distribution, Heat Exchange Enhancement

Type : Cooling Tower Accessories

Cooling Type : Water Cooling

Dimension (L*W*H) : Variable Available in standard and custom sizes

Condition : New

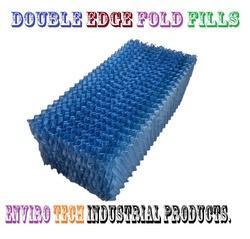

double - edge - fold - fills

Material : Other , PVC (Polyvinyl Chloride)

Application : Cooling Towers, Air Conditioning, Power Plants, Industrial Water Cooling

Type : Double Edge Fold Fills

Cooling Type : Crossflow and Counterflow Cooling Towers

Dimension (L*W*H) : 600mm x 300mm x 150mm (customizable)

Condition : New

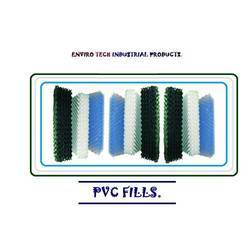

pvc- fills

Material : Other , Rigid PVC

Application : Cooling Towers, Industrial Water Cooling

Type : PVC Fills / Fill Media

Cooling Type : Evaporative

Dimension (L*W*H) : 1200 mm x 600 mm x 150 mm (Common size, customizable)

Condition : New

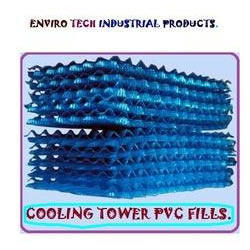

cooling- tower-pvc-fill

Material : Other , PVC (Polyvinyl Chloride)

Application : Cooling Towers, Water Cooling Systems

Type : Honeycomb PVC Fill

Cooling Type : Wet Cooling

Dimension (L*W*H) : 600 mm x 300 mm x 150 mm (Typical)

Condition : New

Send Inquiry

Send Inquiry