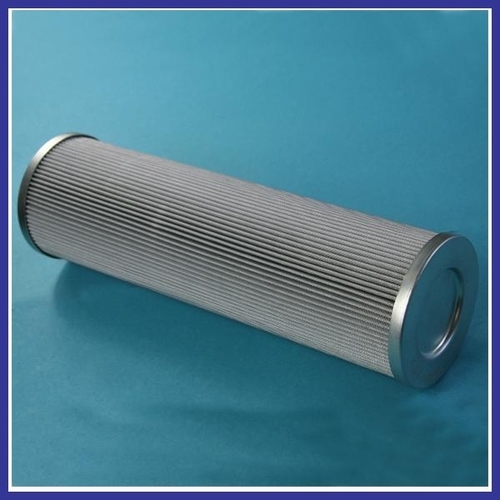

Pleated Stainless Steel Filter From Oil Filter

Pleated Stainless Steel Filter From Oil Filter Specification

- Flow Rate

- 10-4000 LPH (depending on design)

- Efficiency (%)

- Up to 99%

- Cleaning Method

- Washable, Cleanable, Backflush

- Temperature Range

- -20C to 300C

- Pressure

- Up to 25 bar

- Media Type

- Stainless Steel Wire Mesh

- Connecting Type

- Threaded / Flange / Clamp / Customized

- Filtration Grade

- Industrial Grade

- Filter Type

- Pleated Cylindrical Filter

- Capacity

- Customizable as per requirements

- Condition

- New

- Material

- Stainless Steel (SS304/SS316)

- Mesh

- 60-400 Mesh (customizable)

- Diameter

- 30 mm - 200 mm

- Construction

- Welded/Pleated Cylinder

- Medium Filter

- Oil, Water, Chemicals, Liquid Fluids

- Weight

- 300g - 2kg (depending on size)

- Shape

- Cylindrical / Round

- Feature

- Reusable, High Dirt Holding Capacity, High Strength, Corrosion Resistant, Pleated Design

Pleated Stainless Steel Filter From Oil Filter Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Pleated Stainless Steel Filter From Oil Filter

Pleated Stainless Steel Filter From Oil Filter

We have been doing Pleated Stainless Steel Filter so many years to guarantee Pleated Stainless Steel Filter so just rest assured to choose our Pleated Stainless Steel Filter.

Category: Oil Filter & Oil Filter ElementTags: Oil Purifier, oil filter, Pleated Candle Filter Element, Pleated Stainless Steel FilterVersatile Industrial Filtration Solution

This pleated stainless steel filter is meticulously designed to suit a wide range of industrial and commercial oil filters. With availability in different diameters, micron ratings, and end caps, it fits diverse applications, from oil refining to water purification. The robust welded/pleated cylinder construction guarantees reliable filtration under challenging operating conditions.

Superior Durability & Reusability

Built from high-quality stainless steel mesh, this filter resists corrosion and mechanical stress, enabling a lifespan of up to two years with proper maintenance. Its washable and cleanable nature means it can be reused multiple times, reducing replacement frequency and operational costs compared to disposable filters.

Effective Performance Across Conditions

Engineered to handle flow rates up to 4000 LPH and pressures as high as 25 bar, the filter excels in both vertical and horizontal installations. With a temperature tolerance from -20C to 300C and an efficiency rate up to 99%, it delivers consistent results in oil, water, chemical, or liquid fluid applications.

FAQs of Pleated Stainless Steel Filter From Oil Filter:

Q: How do I install the Pleated Stainless Steel Filter in my system?

A: The filter is designed for straightforward vertical or horizontal installation. Depending on your system requirements, it can be connected using threaded, flange, clamp, or custom fittings, ensuring compatibility with most industrial and commercial oil filters.Q: What industries can benefit from using this filter?

A: This filter is suitable for oil, chemical processing, water treatment, food & beverage, and pharmaceutical industries, thanks to its robust build and versatile filtration capabilities. It is ideal for any setting that requires reliable separation of particulate matter from fluids.Q: How often should the filter be cleaned or replaced?

A: Cleaning intervals depend on the contamination level and operating conditions, but the filter is designed for repeated washing, backflushing, or cleaning. With proper maintenance, the lifespan can reach up to two years before replacement is necessary.Q: What are the benefits of using a pleated design?

A: The pleated construction increases the surface area, enhancing dirt holding capacity and filtration efficiency. This leads to extended service intervals and superior contaminant retention without sacrificing flow rate.Q: Can the filter handle different temperatures and pressures?

A: Yes, the filter is engineered to operate efficiently within a temperature range of -20C to 300C and withstand pressures up to 25 bar, making it suitable for demanding industrial processes.Q: Is the micron rating or size customizable to my application?

A: Absolutely. Micron ratings from 5 m up to 200 m, mesh sizes (60-400 mesh), diameter (30 mm - 200 mm), and capacity can all be customized according to your specific filtration requirements.Q: What materials are used for the filter and end caps, and why?

A: The main filter media is composed of SS304 or SS316 stainless steel wire mesh, chosen for its corrosion resistance and strength. End caps can be stainless steel or aluminium, depending on user preference or chemical compatibility for the intended application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

EPE Hydraulic Oil Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel, Glass Fiber, Paper

Feature : High dirt holding capacity, low initial pressure drop, corrosionresistant design, easy installation and replacement

Condition : New

Efficiency (%) : 99% at rated filtration

Replace HYDAC Oil Filter 0850R Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel/Glassfiber/Paper (as per requirement)

Feature : High dirtholding capacity, corrosion resistant, stable filtration precision, easy installation and replacement

Condition : New

Efficiency (%) : 99%

Swimming Pool Water Filter From Water Filters

Minimum Order Quantity : 12 Pieces

Material : Reinforced Fiberglass/Polypropylene

Feature : High efficiency, corrosionresistant, easy installation and maintenance

Condition : New

Efficiency (%) : 98%

HYDAC High Pressure Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel / Aluminium Body

Feature : High pressure filtering, robust design, efficient particle removal

Condition : New

Efficiency (%) : up to 99.9%

Send Inquiry

Send Inquiry