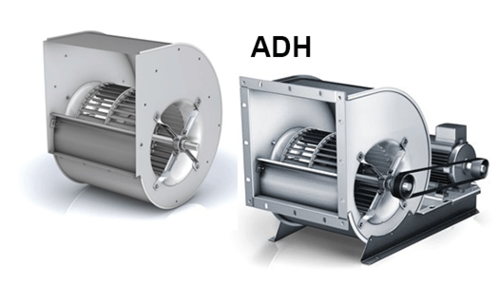

Nicotra Forward Curved Centrifugal Fan ADH 560 R

Nicotra Forward Curved Centrifugal Fan ADH 560 R Specification

- Air Flow

- Max. 8700 m/h

- Temperature

- Suitable for up to 60C ambient temperature

- Orientation

- Horizontal

- Automation Grade

- Manual

- Instruments Type

- Fan

- Power Source

- Electric

- Efficiency

- High energy efficiency, meets ErP directives

- Measurement

- Air Volume / Pressure

- Usage & Applications

- Ventilation, Air Conditioning, Clean Rooms, HVAC systems

- Product Type

- Forward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Cooling System

- Air Cooled

- Noise Level

- Less than 82 dB(A)

- Processing Time

- Continuous Operation

- Capacity

- Up to 8700 m/h

- Voltage

- 400 V / 3 Phase / 50 Hz

- Weight

- Approx. 88 kg

- Dimension (L*W*H)

- Approx. 890 x 890 x 800 mm

- Surface

- Galvanized, anti-corrosive finish

Nicotra Forward Curved Centrifugal Fan ADH 560 R Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque, Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Nicotra Forward Curved Centrifugal Fan ADH 560 R

Nicotra Forward Curved Centrifugal Fan ADH 560 R

Product Benefits

Performance certified is for installation type B - free inlet, ducted outlet. Power rating (kW) does not include transmission losses. Performance ratings do not include the effects of appurtenances (accessories)

Nicotra Gebhardt S.p.A certifies that the fan shown herein is licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and comply with the requirements of the AMCA Certified Ratings Program. The AMCA Certified Ratings Seal applies to air performance ratings only

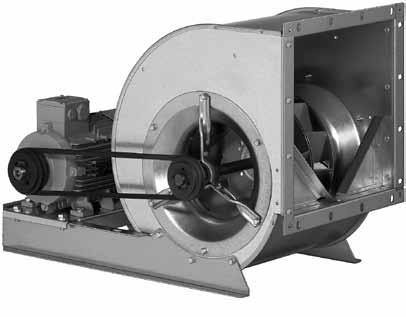

ADH E and ADH G2E series

- Sizes 0160 up to 0560

- Scroll of galvanesed sheet steel with standing seam

- Straight cut off

- New cylindrical impeller with forward-curved blade geometry

- Galvanised shaft

- Pressure up to 2.200 Pa

ADH and ADH G2 Series

- Sizes 0630 up to 1000

- Lap jointed scroll of galvanized sheet steel with Pittsburgh-Seam and V-cut off

- Pressure up to 1.800 Pa

Superior Performance and Efficiency

The Nicotra ADH 560 R fan is engineered for continuous operation while maintaining high energy efficiency. Meeting rigorous ErP directives, it ensures lower operational costs and reliable airflow, making it suitable for broad industrial and commercial installations where air quality and temperature control are paramount.

Durable and Reliable Construction

Crafted from galvanized steel with an anti-corrosive, heavy-duty epoxy finish, this centrifugal fan can withstand harsh environments and provides long-term service. Its robust structure, right rotation, and direct drive mechanism further optimize reliability and reduce maintenance requirements.

Versatile Applications Across Industries

The ADH 560 R caters to various needs, from ventilation and HVAC systems to clean room operations. Its horizontal orientation and base mounting simplify integration into existing airflow systems, making it a versatile choice for manufacturers, suppliers, or wholesalers seeking reliable climate control solutions.

FAQs of Nicotra Forward Curved Centrifugal Fan ADH 560 R:

Q: How is the Nicotra ADH 560 R centrifugal fan typically installed?

A: The fan is base mounted, allowing for stable and secure installation in horizontal orientation within HVAC systems, ventilation ducts, or clean room environments. Its design simplifies the integration process for manufacturers and facility managers.Q: What are the primary benefits of using the ADH 560 R in HVAC applications?

A: It delivers high airflow (up to 8700 m/h) at low noise levels (less than 82 dB(A)) and operates efficiently under continuous conditions, complying with energy efficiency directives. This ensures enhanced air quality, reduced operating costs, and dependable temperature management.Q: Where can the Nicotra ADH 560 R fan be utilized?

A: This fan is ideal for use in ventilation systems, air conditioning units, clean rooms, and general HVAC applications. Its rugged build and anti-corrosive surface make it suitable for both industrial and commercial environments across India.Q: What process does the fan use to ensure air quality?

A: The forward curved double inlet impeller facilitates powerful and even air distribution, effectively managing air volume and pressure to maintain optimal indoor climate conditions as per IEC and ISO standards.Q: When is it advisable to operate the ADH 560 R fan continuously?

A: The fan is designed for continuous operation, particularly in settings where uninterrupted ventilation or climate control is essential, such as manufacturing facilities, laboratories, or large-scale HVAC systems.Q: What level of protection does the ADH 560 R provide for its motor?

A: It features an IP55-rated motor, offering strong protection against dust ingress and water spray, which is critical for prolonged operation in demanding environments.Q: How does the construction of the fan contribute to longevity and ease of maintenance?

A: Its heavy-duty galvanized steel frame with an epoxy finish provides resistance to corrosion and physical wear, minimizing the need for frequent maintenance and extending the service life of the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series ADH Nicotra Forward Curved Centrifugal Fan Category

Nicotra Forward Curved Centrifugal Fan ADH 225 R

Price 16500 INR

Minimum Order Quantity : 1 Piece

Efficiency : High Efficiency

Usage & Applications : HVAC, Ventilation, Air Handling Units, Commercial Spaces

Voltage : 230/415 V

Cooling System : Other, Air Cooled

Nicotra Forward Curved Centrifugal Fan ADH 280 R

Price 20500 INR

Minimum Order Quantity : 1 Piece

Efficiency : High efficiency (up to 80%)

Usage & Applications : HVAC systems, air handling units, ventilation, air purification

Voltage : 380415V AC

Cooling System : Other, Air Cooled

Nicotra Forward Curved Centrifugal Fan ADH 400 R

Price 29000 INR

Minimum Order Quantity : 1 Piece

Efficiency : Up to 75%

Usage & Applications : HVAC, Ventilation, Exhaust, Air Handling Units

Voltage : 415 V AC

Cooling System : Other, Air Cooled

Nicotra Forward Curved Centrifugal Fan ADH 1400 X1

Minimum Order Quantity : 1 Piece

Efficiency : High Efficiency

Usage & Applications : HVAC systems, Ventilation, Exhaust, Industrial air movement

Voltage : 415 V

Cooling System : Air Cooling

Send Inquiry

Send Inquiry