Industrial Magnetic Pressure Gauge

Industrial Magnetic Pressure Gauge Specification

- Sensor Type

- Magnetic

- Display

- Analog

- Seal Material

- Neoprene Rubber

- Grade

- Industrial

- Outer Size

- 100 mm

- Thread

- 1/2 BSP

- Bourdon Tube

- Phosphor Bronze

- Material

- Stainless Steel

- Dial Material

- Aluminum

- Pointer Material

- Aluminum

- Processing Type

- Machined

- Diameter

- 100 mm

- Glass Size

- 100 mm

- Mount Type

- Bottom / Back

- Scale Range

- 0-10 kg/cm

- Accuracy

- 1% FSD

- Finishing

- Powder Coated

- Measure Pressure Of

- Air, Gas, Liquid

- Accessories

- Mounting Bracket

About Industrial Magnetic Pressure Gauge

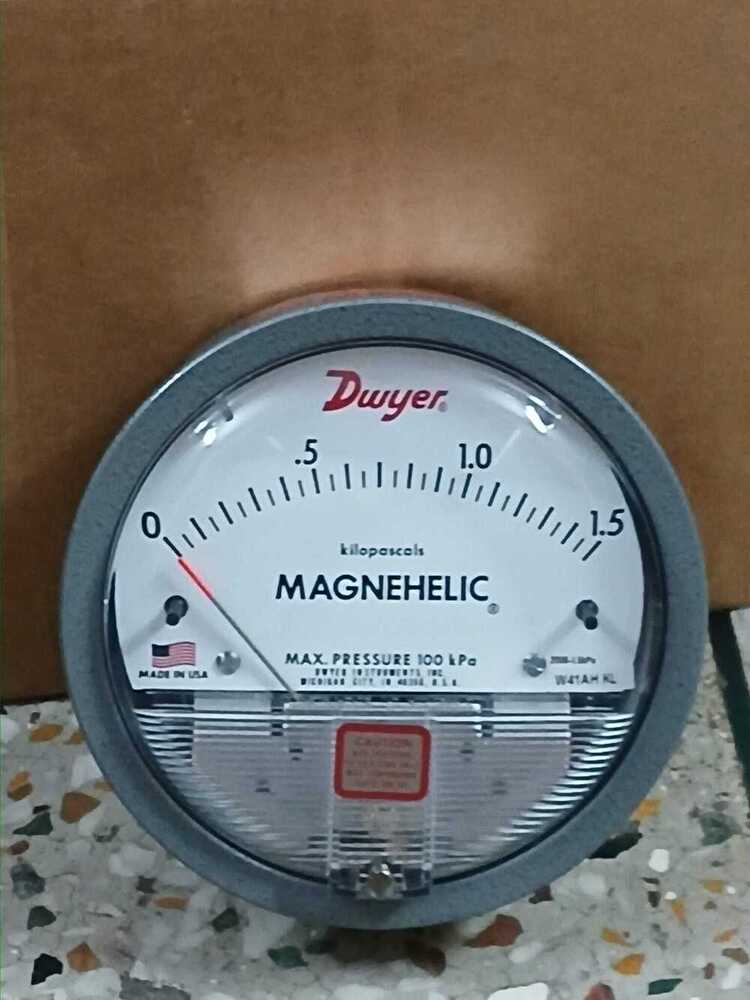

Industrial Magnehelic Gauges

We are the leading manufacturer and exporter of a quality tested assortment of Industrial Magnehelic Gauges. Our range is widely used in checking the automatic valves and gas-air ratio controls, further in medical equipments also to monitor blood and respiratory pressures. Besides it is used to measure the fan and blow pressures, liquid levels and pressures in fluidic systems. Operated by a diaphragm our product is low in cost and is available in different specifications ranging from

0-10,

0-25,

0-40,

0-50,

0-100 MM Wc , And

0- 60 pA,

0-250 pA.

Uses : Used for high accuracy-guaranteed within 2% of full scale and for the wide choice of 81 models available to suit your needs precisely.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Engineered for High-Performance Industrial Monitoring

Optimized to monitor air, gas, and liquid pressure in demanding industrial applications, this pressure gauge is built for accuracy and durability. Its stainless steel 304 case and IP65 protection make it suitable for harsh environments where reliability is critical. The analog display offers precise readings, while robust components like a powder-coated finish, toughened glass, and phosphor bronze Bourdon tube enhance longevity and resistance to wear.

User-Friendly and Versatile Installation

Install the gauge with ease, thanks to a mounting bracket and versatile bottom or back connection options (1/2 BSP thread). The clear 100 mm analog dial ensures quick pressure assessment, while the compact design and light weight (approx. 500 gm) make it adaptable for various equipment or panel setups. Its designed to simplify industrial monitoring, boosting both operational safety and efficiency.

FAQs of Industrial Magnetic Pressure Gauge :

Q: How does the magnetic pressure gauge function in industrial process monitoring?

A: The magnetic pressure gauge measures gauge pressure using a phosphor bronze Bourdon tube and brass movement. As the process media applies pressure, the tube flexes, and the magnetic sensor transmits the movement to the analog pointer. This allows for accurate, real-time monitoring of air, gas, or liquid pressure during industrial operations.Q: What are the advantages of the Stainless Steel 304 case and IP65 protection rating?

A: The Stainless Steel 304 case provides excellent corrosion resistance, making it suitable for harsh environments. The IP65 rating ensures the gauge is dust-tight and protected against water jets, significantly enhancing its longevity and reliability in demanding industrial conditions.Q: When is recalibration of this factory-calibrated pressure gauge recommended?

A: Although the gauge is factory calibrated, periodic recalibration is advisable based on your companys quality protocol, the operating environment, and frequency of usetypically every 6 to 12 months or as specified by regulatory standards to maintain measurement accuracy.Q: Where should the pressure gauge be installed for optimal performance?

A: For optimal performance, mount the gauge in a position where it is easily visible and protected from excessive vibration, extreme temperatures, or direct sun. The bottom or back mounting option (with 1/2 BSP thread) offers flexibility according to your equipment or panel layout.Q: What does the overload capacity of 130% FS signify?

A: The overload capacity of 130% Full Scale (FS) means the gauge can temporarily handle pressures up to 130% of its maximum range (13 kg/cm for a 0-10 kg/cm gauge) without suffering permanent damage or affecting its accuracy.Q: How can this gauge benefit industrial process operations?

A: By providing precise and reliable pressure readings, this gauge helps maintain process safety, prevent equipment damage, and ensure product quality. Its robust design reduces the need for frequent replacements, contributing to operational efficiency and cost savings.Q: What is included as standard with the gauge and what materials are used for key parts?

A: The pressure gauge comes standard with a mounting bracket for installation. Key materials include stainless steel for the case, toughened glass for the viewing window, neoprene rubber for the seal, and aluminum for the dial and pointer, ensuring durability and clear measurement visibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Magnehelic Differential Pressure Gauge Wholesaler Category

DWYER OMEGA Magnehelic Differential Pressure Gauge From Ganpati Dham Industrial Area Bahadurgarh

Display : Analog

Mount Type : Back

Material : Metal Alloy

Processing Type : Standard

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Series A3 Digital Differential Pressure Gauges

Display : 4digit Digital LCD Display

Mount Type : Other, Panel Mount/Wall Mount

Material : Other, ABS Plastic Housing, Aluminium Panel

Processing Type : Other, Microprocessor Based Digital Processing

Accuracy : 1% F.S. (Full Scale)

Accessories : Mounting Bracket, Screws, User Manual

Photohelic Switch Gauges

Display : Analog needle and scale

Mount Type : Other, Panel mount

Material : Other, Metal enclosure

Processing Type : Pressure and electronic switch monitoring, Other

Accuracy : Standard industry accuracy details not visible

Accessories : None visible in the image

Magnehelic Gauge

Display : Analog

Mount Type : Surface or panel mounting, Other

Material : Other, Diecast aluminum case

Processing Type : Other, Mechanical Differential Pressure Gauge

Accuracy : 2% of full scale

Accessories : Standard accessories available

Send Inquiry

Send Inquiry