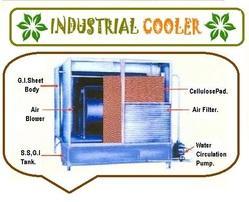

Industrial Cooler

Industrial Cooler Specification

- Refrigerating Capacity

- 25000 Kcal/h

- Material

- Powder Coated Steel Body

- Air Flow

- 18000 m3/h

- Motor

- Heavy Duty Copper Motor, 1.5 HP

- Application

- Industrial Cooling, Warehouses, Workshops, Factories

- Condition

- New

- Type

- Industrial Air Cooler

- Dimension (L*W*H)

- 1400 x 1100 x 1700 mm

- Power Supply

- AC 220-240V, 50/60Hz

- Voltage

- 220 V

- Cooling Type

- Evaporative Cooling

- Nozzle Material

- Brass

- Cooling Coil Material

- Copper

- Water Flowing Rate

- 60 L/min

- Water Pump Motor

- 0.25 HP

- Noise Control

- 60 dB

- Compressor

- Hermetically Sealed Compressor

About Industrial Cooler

From the initial stage of our establishment in 1995, Enviro Tech Industrial Product is manufacturing, exporting and supplying Industrial Cooler. The offered cooler is extensively demanded in the market to installed in industries for cooling purpose. This cooler is manufactured under the supervision of our dexterous professionals using supreme quality components and ultramodern techniques. Besides, the provided Industrial Cooler can be availed from us in several technical specifications at affordable prices.

Features:

- Excellent cooling

- Less power consumption

- Rugged design

- Low maintenance

Specifications:

- Capacity Available : 2000 to 40000 cfm with single blower & 4000 to 80000 cfm with single & multiple blowers

- Base Frame: the total assembly is mounted on a horizontal member of heavy mild steel channel

- Fan Section : constructed in GI Sheet with inspection doors

- Wet Section : constructed in GI Sheet

- Water Tank : constructed in GI /SS

- Blower : Dynamically Balaced Forward Curved, Didw Type Make Enviro Tech / Imported

- Cellulose Paper Pad :Â Imported

- Electric Motor : Three Phase, tefc squirrel cage induction Motor of Standard  Makes (Crompton, ABB and Kirloskar etc

- Drive Pulley : V-Groove with/without taper lock hub

- V-Belts : Fenner Make

- Pump: Monoblock Make Crompton / Kirloskar

- Filter: HDPA / Aluminum / GI Mesh Filter, Micro Vee, HEPA as per requirement

- Pipe Fittings : PVC / GI Piping with all necessary fittings such as float valve, quick fill, overflow & drain ports

APPLICATION :

- Air conditioning

- Showroom

- Shopping Mal

- Restaurant & bar

- Hotels

- Office

- Call Center

- Building

- Schools

- Studio

- Institute

- Hospital

- Pharma company

- Clean Room

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Exceptional Cooling Performance

Delivering a powerful 25,000 Kcal/h refrigerating capacity, this industrial cooler is engineered for demanding applications. The axial fan, coupled with high-quality cellulose pads and a heavy-duty copper motor, ensures optimal air distribution and effective temperature reduction in large areas.

Efficient Design and Durability

Constructed with a powder-coated steel body and copper cooling coils, the cooler is built to withstand industrial environments. Its heavy-duty castor wheels make relocation straightforward, while the hermetically sealed compressor guarantees longevity and stable operation.

Flexible Humidity Control and User Convenience

Manage humidity with either manual or automatic settings, easily adapting to diverse climate requirements. The floor-standing design, accessible controls, and large water tank enhance ease of use and minimize maintenance interruptions.

FAQs of Industrial Cooler:

Q: How does the industrial air cooler operate within large spaces like factories or warehouses?

A: The cooler utilizes evaporative cooling technology, cellulose pads, and a powerful axial fan to circulate up to 18,000 m/h of air, effectively lowering ambient temperatures in sizable areas such as factories, warehouses, and workshops.Q: What maintenance is required to keep the cooler running efficiently?

A: Regularly check and refill the 120-litre water tank, ensure the cellulose pads are clean, and inspect the water pump and filters for blockages. Occasional cleaning of the powder-coated steel body and castor wheels is also recommended to maintain optimal performance.Q: When is it advisable to use manual versus automatic humidity control?

A: Manual control is beneficial when environmental conditions demand precise adjustment, while automatic control offers set-and-forget convenience for regular operations, maintaining a consistent humidity level based on sensor feedback.Q: Where should the industrial air cooler be installed for best results?

A: Place the cooler in well-ventilated, unobstructed floor locations within the area being cooled. Ensure proximity to a reliable water source for refilling and access to a standard 220 V power supply.Q: What are the main benefits of the heavy-duty copper motor and powder-coated steel body?

A: The copper motor provides robust, energy-efficient operation and increased reliability, while the powder-coated steel body enhances durability, corrosion resistance, and longevity demanded by harsh industrial use.Q: How does the noise control feature contribute to a better working environment?

A: Operating at a quiet 60 dB, the cooler minimizes noise in busy locations, ensuring a more comfortable and productive environment for workers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Cooling System Category

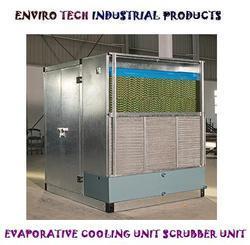

Evaporative Cooling Unit Scrubber

Motor : 1.5 HP

Nozzle Material : Brass

Voltage : 220380 V

Cooling Type : Evaporative

Material : Other , Mild Steel / FRP

Air Flow : 18000 m/h

Air Washer System

Motor : 1 HP to 3 HP (as per capacity)

Nozzle Material : Brass / ABS Plastic

Voltage : 380440 V

Cooling Type : Evaporative Cooling

Material : Other , Mild Steel (MS) / Galvanized Sheets with Powder Coating

Air Flow : 6000 25000 m/hr (varies by model)

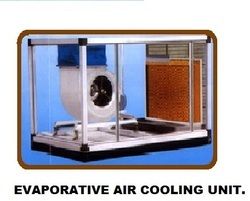

Evaporative Air Cooling Unit

Motor : 1.1 kW, Single Phase

Nozzle Material : Plastic/ABS

Voltage : 220240 V

Cooling Type : Evaporative

Material : Other , UVstabilized Polypropylene Plastic

Air Flow : 18000 m/h

Ductable Unit Floor Mounted

Motor : High Efficiency TEFC Motor

Nozzle Material : Brass Nozzle

Voltage : 415 V

Cooling Type : Air Cooled

Material : Other , Galvanized Steel Sheet

Air Flow : 5000 CFM

Send Inquiry

Send Inquiry