Air Washer System

Air Washer System Specification

- Material

- Mild Steel (MS) / Galvanized Sheets with Powder Coating

- Motor

- 1 HP to 3 HP (as per capacity)

- Refrigerating Capacity

- Not Applicable (works on evaporative cooling principle)

- Application

- Industrial and Commercial Cooling, Textile Mills, Warehouses, Factories, Offices

- Air Flow

- 6000 - 25000 m/hr (varies by model)

- Condition

- New

- Type

- Evaporative Air Cooling System / Air Washer System

- Dimension (L*W*H)

- Customized as per requirement, e.g. 1200 x 1000 x 1200 mm

- Power Supply

- 3-Phase, 50 Hz

- Voltage

- 380-440 V

- Cooling Type

- Evaporative Cooling

- Nozzle Material

- Brass / ABS Plastic

- Cooling Coil Material

- G.I./SS/Aluminum

- Water Flowing Rate

- 80-200 LPH (Liters Per Hour) (varies by model)

- Water Pump Motor

- 0.5 HP to 2 HP (depending on capacity)

- Noise Control

- < 70 dB

- Compressor

- Not Applicable / Not Required

About Air Washer System

Our enterprise is an award winning organization instrumental in offering excellent quality Air Washer System. Provided system finds wide application in various domestic, commercial & industrial sectors to remove suspended particles, bacteria, virus, dirt, odor, etc. with the help of air. This system is designed and manufactured by utilizing superior quality membrane and allied components in accordance with international quality standards. Moreover, we are offering this Air Washer System at marginal prices within promised time frame.

Features:

- Less maintenance required

- Simple to operate

- High functionality

- Excellent performance

- Manufactures High Quality Single Skin Air Washers as per coustomer requirement under the brand name Enviro Tech Industrial Products

- Capacity Available : 2000 to 40000 CFM with single Blower & 4000 to 80000 CFM with Single & multiple blowers.

- Base Frame : The total assembly is mounted on a horizontal member of channels.

- Fan Section : Constructed in GI/SS Sheet with Inspection Doors.

- Wet Section : Constructed in GI/SS Sheet.

- Water Tank : Constructed in GI /SS.

- Blower : Dynamically Balaced Forward Curved, DIDW Type Make Enviro Tech Industrial Products / Imported.

- Cellulose Paper Pad : Imported

- Electric Motor : Three Phase, TEFC squirrel cage induction motor of standard makes

- Drive Pulley : V-Groove with / without Taper Lock hub.

- V-Belts : Fenner make.

- Pump : standard makes

- Filter : HDPE/Aluminum/GI Mesh Filter, Micro Vee, as per requirement.

- Pipe Fittings : PVC/GI piping with all Necessary fittings such as float valve, quick fill, overflow & drain ports.

- Pay Mode Terms: T/T (Bank Transfer)

Custom-Made for Varied Applications

Each air washer system is engineered to meet specific industrial and commercial requirements. Choose from automation grades, installation methods, materials, and color options to fit your space. Our systems are suitable for large-scale cooling in textile mills, warehouses, and offices. You can specify dimensions, outlet shapes, and panel types to match your sites requirements, ensuring seamless integration and optimal performance.

Efficient Evaporative Cooling System

Built on the evaporative cooling principle, our air washers offer a sustainable alternative to traditional refrigeration. With no compressors required, these systems use water evaporation to reduce temperatures. The combination of reliable water pumps and high-capacity motors ensures steady air flow and humidity control. Choose between standard manual or advanced sensor-based humidity management to maintain desired comfort levels in your workspace.

Reliable Support & Maintenance

Our commitment extends beyond product delivery. We offer comprehensive on-site installation and maintenance support across India. This service ensures rapid deployment, seamless operation, and maximum system longevity. Regular inspection and maintenance keep the system efficient and minimize downtime, while our expert team provides immediate assistance for troubleshooting or part replacement as needed.

FAQs of Air Washer System:

Q: How is the Air Washer System installed in different settings?

A: The system can be installed either floor-mounted or duct-mounted, depending on your facilitys requirements. Our installation team ensures that the model is perfectly positioned and integrated with existing ventilation or air handling ductwork, following the sites specifications.Q: What types of filters and cooling pads are used in this air washer system?

A: The system utilizes a pre-filter for initial dust and particulate removal, combined with a cellulose paper pad that enhances the evaporative cooling process by maximizing water retention and air contact.Q: When should I schedule maintenance for optimal operation?

A: Regular maintenance should be scheduled every 36 months, depending on usage and environmental conditions. Our on-site support includes inspection, cleaning, and any necessary part replacements to keep your system operating efficiently.Q: Where can this air washer system be effectively used?

A: It is ideal for industrial and commercial environments such as textile mills, warehouses, production plants, and large office spaces where effective evaporative cooling and improved indoor air quality are required.Q: What is the process of humidity control in this system?

A: Humidity control is available as a manual adjustment or an optional sensor-based system, allowing you to set and stabilize indoor humidity levels according to your operational needs.Q: How does the system benefit my facility compared to conventional air conditioning?

A: This air washer system leverages evaporative cooling, requiring no compressor or conventional refrigerant cycle. This results in lower energy consumption, easier maintenance, and a significant reduction in cooling costs, while providing fresh, filtered air.Q: What are the power requirements and noise levels for this system?

A: The air washer operates on a 3-phase, 380-440V power supply with motors ranging from 1 HP to 3 HP. It is designed to maintain noise levels below 70 dB, ensuring a comfortable and quiet environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Cooling System Category

Ductable Unit Floor Mounted

Air Flow : 4500 CFM

Application : Industrial/Commercial HVAC

Condition : New

Voltage : 415 V

Cooling Type : Direct Expansion

Nozzle Material : Stainless Steel

Ductable Unit Floor Mounted

Air Flow : 5000 CFM

Application : Commercial & Industrial Air Conditioning

Condition : New

Voltage : 415 V

Cooling Type : Air Cooled

Nozzle Material : Brass Nozzle

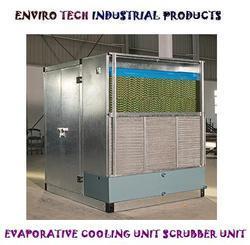

Evaporative Cooling Unit Scrubber

Air Flow : 18000 m/h

Application : Industrial Air Cooling, Dust Collection, Air Scrubbing

Condition : New

Voltage : 220380 V

Cooling Type : Evaporative

Nozzle Material : Brass

Air Curtain

Air Flow : 18002450 m/h

Application : Entrance and Exit Doors, Hotels, Hospitals, Commercial Complexes, Cold Storages

Condition : New

Voltage : 220240V

Cooling Type : Air Cooling

Nozzle Material : Aluminum

Send Inquiry

Send Inquiry