HYDAC High Pressure Filter From Hydraulic Oil Filters

HYDAC High Pressure Filter From Hydraulic Oil Filters Specification

- Connecting Type

- Threaded / Flanged

- Media Type

- Microglass, Stainless Steel Mesh

- Cleaning Method

- Replaceable element

- Efficiency (%)

- up to 99.9%

- Capacity

- Varies by model; standard 5 to 50 liters

- Flow Rate

- Up to 600 LPM (Liters Per Minute)

- Pressure

- Up to 315 bar (4568 psi)

- Temperature Range

- -10C to +120C

- Filtration Grade

- ISO 16889 compliant

- Filter Type

- High Pressure Filter

- Condition

- New

- Material

- Stainless Steel / Aluminium Body

- Mesh

- Microglass fiber / Stainless steel wire mesh

- Diameter

- Standard sizes: 50 mm to 150 mm (custom options available)

- Construction

- Cartridge type, Steel bowl with head assembly

- Medium Filter

- Hydraulic Oil

- Weight

- 4 - 12 kg (depending on model)

- Shape

- Cylindrical

- Feature

- High pressure filtering, robust design, efficient particle removal

HYDAC High Pressure Filter From Hydraulic Oil Filters Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

About HYDAC High Pressure Filter From Hydraulic Oil Filters

HYDAC High Pressure Filter From Hydraulic Oil Filters

Please note all the replacement HYDAC series oil filter and oil filter elements are produced by us whose quality are great enough to meet your requirement meanwhile own very competitive price which can be used well to replace HYDAC oil filter and oil filter elements that produced by HYDAC. Please contact HYDAC directly in case you need HYDAC original produced oil filter and oil filter elements.

Categories: Replacement Filter Series, HYDAC Filter Tags: HYDAC Oil Filter

Element, HYDAC Oil Filter, Oil Filter Element, HYDAC High Pressure Filter

Superior Filtration and Efficient Performance

The HYDAC High Pressure Filter ensures optimal particle removal efficiency up to 99.9%, safeguarding sensitive components in hydraulic systems. Its cartridge-type construction is easy to replace, reducing downtime and maintenance efforts. High dirt holding capacity, proven by rigorous ISO test dust standards, allows extended intervals between changes, making it ideal for continuous operation in critical environments.

Versatile Compatibility and Reliable Design

This filter caters to a wide range of hydraulic applications with support for both mineral and synthetic fluids, a robust body in stainless steel or aluminium, and various end connection sizes. The corrosion-resistant build and high pressure rating up to 315 bar provide long-lasting reliability, even in aggressive industrial conditions.

FAQs of HYDAC High Pressure Filter From Hydraulic Oil Filters:

Q: How do I determine the correct HYDAC high pressure filter model for my hydraulic system?

A: Selecting the right model depends on your systems required flow rate, working pressure, and connection size. Consider your applications operating fluid, filtration grade, and compatible seal materialsViton or Nitrile. For support in model selection, refer to the flow rate range (up to 600 LPM), pressure limits (up to 315 bar), and connection types (BSP/NPT/SAE from 1/2 to 2).Q: What is the process for replacing the filter element?

A: To replace the element, first depressurize the hydraulic system, then unscrew the steel bowl from the filter head assembly. Remove the used filter element and insert a new compatible cartridge. Ensure all seals are correctly seated before reassembling. The process is straightforward due to the replaceable cartridge-type construction, minimizing downtime.Q: When should I change the HYDAC filter element?

A: Element replacement is recommended once the clogging indicatoreither visual or electricalsignals a blockage. For optimal performance, monitor the system regularly and replace elements when indicated or according to your plants maintenance schedule, considering filtration grade and dirt holding capacity.Q: Where can this high pressure filter be installed within hydraulic systems?

A: The HYDAC High Pressure Filter is designed for in-line installation, suitable for placement in the pressure line of hydraulic circuits. Its versatile mounting makes it ideal for both new and retrofit applications in industrial, mobile, and manufacturing settings across India.Q: What fluids and environments is the filter suitable for?

A: This high pressure filter is compatible with mineral oil and synthetic hydraulic fluids, meeting corrosion resistance requirements for aggressive environments. Its robust build from stainless steel or aluminium body ensures dependable performance in challenging industrial conditions.Q: How does the HYDAC filter benefit my hydraulic system?

A: By efficiently removing contaminants up to 99.9% as per ISO 16889, the filter prolongs equipment life, reduces unscheduled downtime, and maintains system performance. Its high dirt holding capacity and compliance with international ISO standards ensure reliability and operator safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

Pleated Candle Filter Element From Oil Filter

Minimum Order Quantity : 12 Pieces

Feature : High dirt holding capacity, Easy installation, Consistent filtration performance, Pleated design for larger surface area

Condition : New

Material : Stainless Steel / Metal (as per requirement)

Mesh : Customizable (commonly 5 to 200 microns)

Weight : Depends on dimensions (typically 300 g 2 kg)

PALL Low Pressure Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Feature : High dirtholding capacity, easy element replacement, low pressure drop, and reliable performance.

Condition : New

Material : Stainless Steel / Alloy Steel

Mesh : Microglass fiber, cellulose, or wire mesh

Weight : Dependent on model (approx. 1.56 kg)

Parker From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Feature : High dirtholding capacity, Durable construction, Compact design

Condition : New

Material : Stainless Steel

Mesh : Yes

Weight : Approx. 2.5 kg

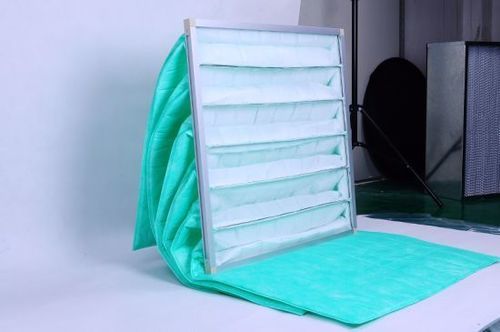

F6 Bag Filter From High Quality Air Filters

Minimum Order Quantity : 12 Pieces

Feature : High efficiency fine dust removal, low initial resistance, large dust holding capacity

Condition : New

Material : Synthetic Fiber, Nonwoven Fabric, Galvanized Iron (GI) Frame, Aluminium Frame

Mesh : Fine Mesh for Particle Filtration

Weight : Approx. 24 kg (depends on size)

Send Inquiry

Send Inquiry