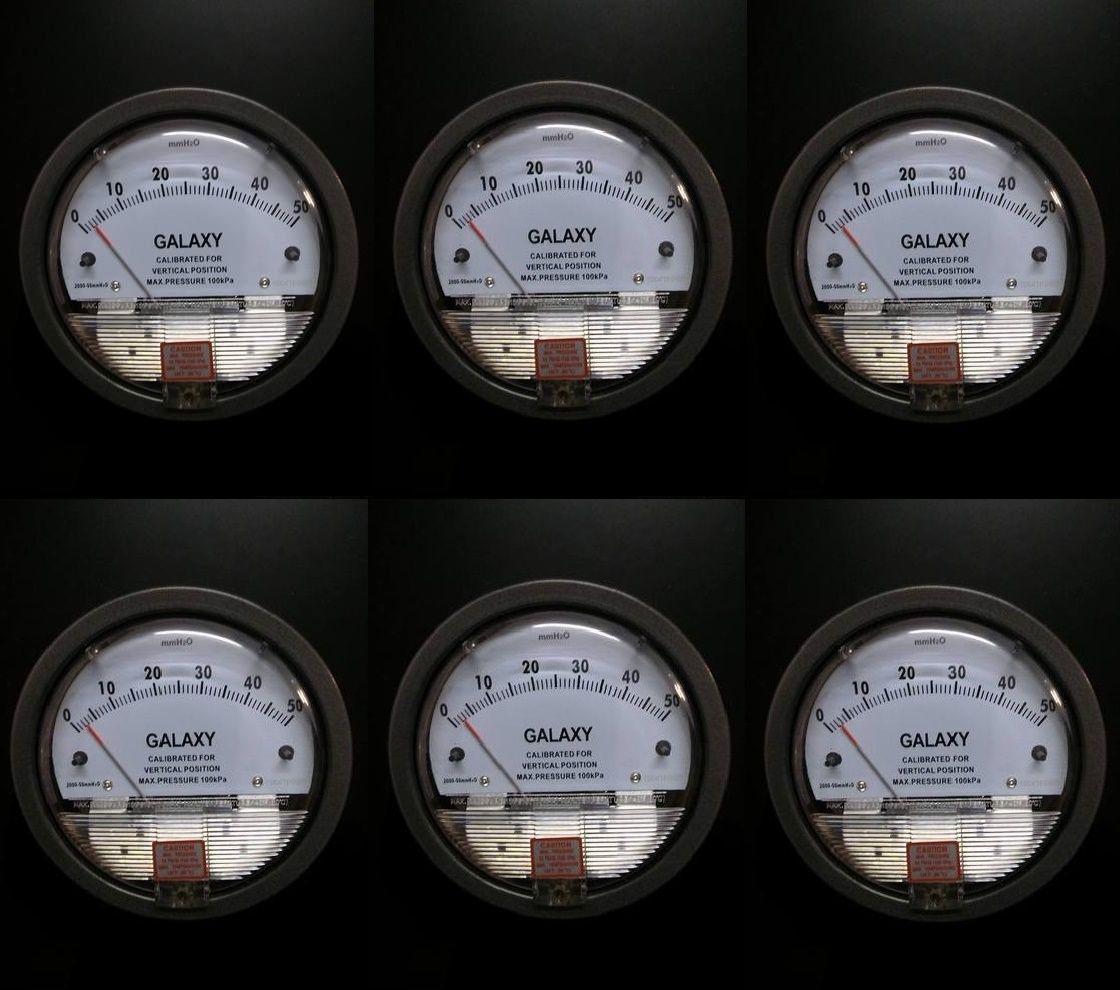

Galaxy Magnehelic Gauge Model G2000-25MM Range 0-25 MM WC

MOQ : 12 Pieces

Galaxy Magnehelic Gauge Model G2000-25MM Range 0-25 MM WC Specification

- Outer Size

- 110 mm approx.

- Thread

- 1/8 NPT Female

- Grade

- Industrial Grade

- Display

- Analog Dial

- Bourdon Tube

- Not Applicable (Diaphragm based)

- Sensor Type

- Diaphragm Sensitive Element

- Seal Material

- Neoprene Rubber

- Material

- Pressure Die Cast Aluminum Body

- Dial Material

- Aluminum with Baked White Finish

- Pointer Material

- Aluminum Black Painted

- Processing Type

- Precision Calibrated

- Diameter

- 4 inches (100 mm)

- Glass Size

- 100 mm approx.

- Mount Type

- Surface/Panel Mount

- Scale Range

- 0-25 MM WC (Water Column)

- Accuracy

- 2% of Full Scale

- Finishing

- Powder-Coated Casing

- Measure Pressure Of

- Low Differential Air/Gas Pressure

- Accessories

- Two plastic tubing adaptors, three mounting screws

Galaxy Magnehelic Gauge Model G2000-25MM Range 0-25 MM WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cheque, Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Galaxy Magnehelic Gauge Model G2000-25MM Range 0-25 MM WC

Galaxy MEGNAHELIC GAUGE Model G2000-25MM Range 0-25 MM WC

Series G2000 are for measuring fan and blower pressures, filter resistance, furnace draft, pressure drop across orifice plates, monitoring blood and respiratory pressures in medical care equipment With simple, frictionless movement parts,It can quickly indicate low air or non-corrosive gas pressures, either positive, negative or differential It can resist shock, vibration and over-pressures.

Technical Specification

- Model G2000-25MM

- Range 0-25 MM WC

- Mount in Industry Standard holes

- Shock Resistance

- It can sustain in vibration and in over pressure

- Accuracy 2.5%

- Die cast aluminum Housing

Series G2000 are for measuring fan and blower pressures, filter resistance, furnace draft, pressure drop across orifice plates, monitoring blood and respiratory pressures in medical care equipment With simple, frictionless movement parts,It can quickly indicate low air or non-corrosive gas pressures, either positive, negative or differential It can resist shock, vibration and over-pressures.

Technical Specification

- Pressure Limits: Fig to 15 PSI (-0.677 bar to 1.034 bar)

- Media Compatibility: Air and compatible gasses

- Accuracy: +1- 2% full scale (+/- 3% an -0 and +/-4% on -00) throughout range at 70 F (21 C)

- Temperature Ranges: 20 to 140 F (-7 to 60 C)

- Housing Material: Die cast aluminum case and bezel (ABS for P2000), with acrylic cover

- Process Connection: 1/8 female NPT duplicate high and low pressure taps one pair side and one pair back.

- Weight: 1 lb 2 oz (510 g)

- Accessories: Two 1/8 NPT barbed frftings,two 1/8 NPT plugs, and three mounting tabs and screws

- Warranty: 1 years Approvals: Roi-IS, CE

-

Durable Construction and Precision Engineering

Manufactured with a pressure die-cast aluminum body, the G2000-25MM delivers outstanding strength and reliability. Its powder-coated casing and dust/corrosion resistance ensure long-lasting performance. Precision calibrated using a diaphragm-sensitive element, this gauge provides accurate, repeatable measurements with a 2% full-scale accuracy.

Versatile Applications Across Industries

This differential pressure gauge is tailored for a wide range of settings including HVAC systems, clean rooms, and blower/filter monitoring. It effectively measures low differential air and gas pressures, as well as air velocity and duct static pressures. Suitable for surface or panel mounting, it adapts seamlessly to diverse industrial requirements.

Easy Installation and User Convenience

Equipped with side/back 1/8 NPT female pressure connections and mounting accessories, the G2000-25MM promises straightforward installation. The large analog display, external screw for zero adjustment, and transparent window (acrylic/polycarbonate) enhance operational convenience and readout clarity for efficient monitoring.

FAQs of Galaxy Magnehelic Gauge Model G2000-25MM Range 0-25 MM WC:

Q: How do I install the Galaxy Magnehelic Gauge Model G2000-25MM?

A: The gauge can be mounted on surfaces or panels using the three provided screws. Connect your air or gas lines to the 1/8 NPT female ports (either side or back as needed), and use the included plastic tubing adaptors if required. Ensure installation aligns with the airflow direction for accurate measurement.Q: What types of applications is this differential pressure gauge suitable for?

A: It is ideal for monitoring HVAC systems, clean rooms, filters, blowers, air velocity, and duct static pressure. Its design makes it especially effective in environments requiring precise low differential air or gas pressure measurement.Q: When should I perform zero adjustment on the gauge?

A: Zero adjustment should be performed before initial use and periodically during routine maintenance or calibration checks. This ensures ongoing measurement accuracy and is conveniently completed using the external adjustment screw.Q: Where can I read the differential pressure value on the gauge?

A: The differential pressure value is displayed on the large, analog dial visible through the transparent acrylic or polycarbonate window. The clear white dial with black pointer allows quick and easy pressure reading.Q: What is the process for routine maintenance of the G2000-25MM gauge?

A: Regularly inspect the gauge for dust, damage, or leaks. Clean the window with a soft cloth, check connections and seals (neoprene rubber), and perform zero adjustment as necessary. Always follow manufacturer guidelines for best results.Q: How does using the G2000-25MM benefit my operation?

A: It enables continuous and precise monitoring of low differential pressures, ensuring prompt detection of system inefficiencies or filter clogs. Its durable construction and easy installation reduce downtime and maintenance effort, supporting consistent operational performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in GALAXY MACK TAIBAN USA MAGNEHELIC GAUGE WHOLESALE Category

Galaxy Differential Pressure Gauges In Jharkhand

Price 4500 INR / Piece

Minimum Order Quantity : 100 Pieces

Display : Analog

Scale Range : MM WC/ CM / PAC / KPA / INCH / PSI / MBAR

Measure Pressure Of : Gas

Diameter : 4 inch / 100 MM

Galaxy Magnehelic Gauge Model G2000-50MM Range 0-50 MM WC

Price 2600 INR

Minimum Order Quantity : 12 Pieces

Display : Analog

Scale Range : 050 MM WC

Measure Pressure Of : Other, Air and Noncorrosive Gases

Diameter : 50 mm

Galaxy Digital Display Pressure Transmitter 0-10 bar

Price 12500 INR

Minimum Order Quantity : 12 Pieces

Display : yas

Galaxy Mack Digital Pressure Gauge

Price 8000 INR

Minimum Order Quantity : 12 Pieces

Display : yas

Measure Pressure Of : Steam, Oil, Gas

Send Inquiry

Send Inquiry