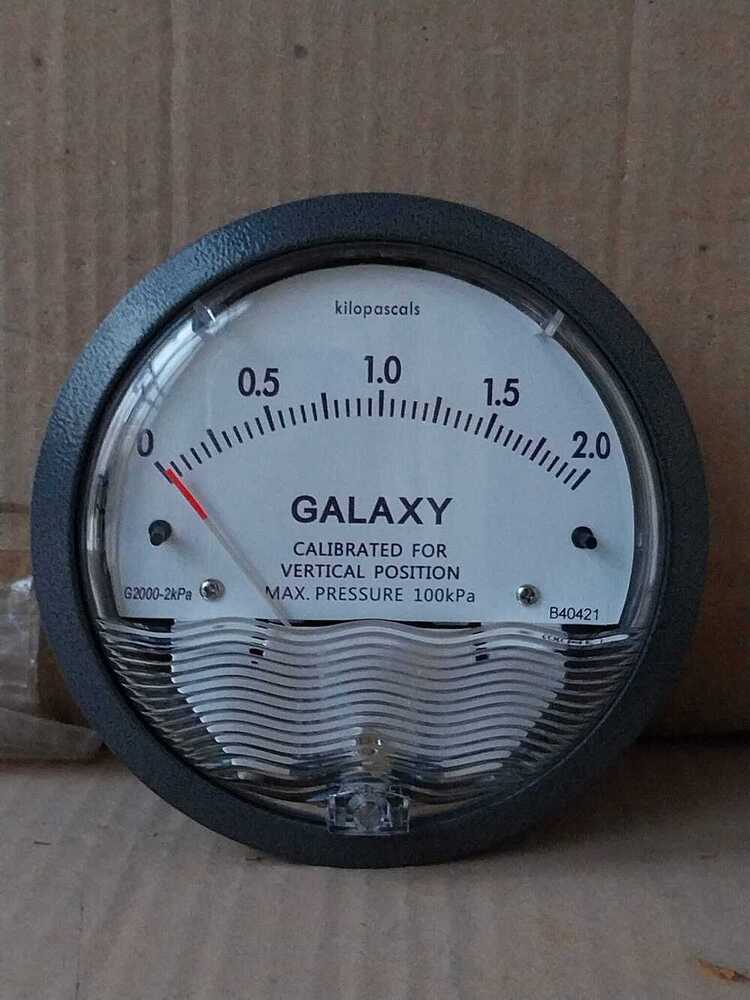

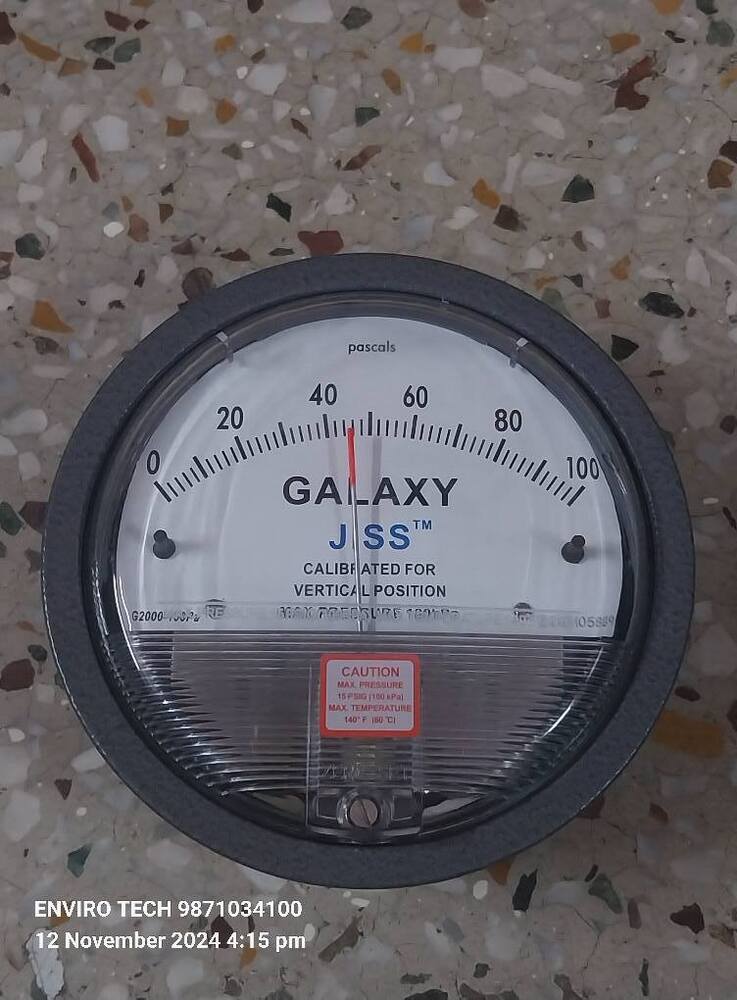

Galaxy Magnehelic Gauge Model G2000-10MM Range 0-10 MM

Galaxy Magnehelic Gauge Model G2000-10MM Range 0-10 MM Specification

- Seal Material

- Silicone Rubber

- Grade

- Industrial Grade

- Bourdon Tube

- Not Applicable (Uses Diaphragm Mechanism)

- Thread

- 1/8 NPT Female

- Sensor Type

- Diaphragm Sensor

- Outer Size

- Approx. 110 mm Diameter

- Display

- Analog

- Material

- Acrylic Housing, Aluminum Backplate

- Dial Material

- Printed Aluminum

- Pointer Material

- Plastic

- Processing Type

- Machined, Assembled

- Diameter

- 110 mm

- Glass Size

- Approx. 102 mm

- Mount Type

- Surface / Flush Mount with Front Flange

- Scale Range

- 0-10 mm (Water Column)

- Accuracy

- 2% of Full Scale

- Finishing

- High Gloss Black Acrylic Housing

- Measure Pressure Of

- Low Differential Pressure (Gases & Air)

- Accessories

- Mounting Screws, Two Plastic Tube Adaptors, Instruction Sheet

Galaxy Magnehelic Gauge Model G2000-10MM Range 0-10 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Delivery Point (DP), Cheque, Cash Advance (CA)

- Delivery Time

- 7 DAY Months

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Eastern Europe, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About Galaxy Magnehelic Gauge Model G2000-10MM Range 0-10 MM

Galaxy MEGNAHELIC GAUGE Model G2000-10MM Range 0-10 MM WC

- Model G2000-10MM

- Range 0-10 MM WC

- Mount in Industry Standard holes

- Shock Resistance

- It can sustain in vibration and in over pressure

- Accuracy 2.5%

- Die cast aluminum Housing

Technical Specification

Pressure Limits: 20³ Fig to 15 PSI (-0.677 bar to 1.034 bar)

Media Compatibility: Air and compatible gasses

Accuracy: +1- 2% full scale (+/- 3% an -0 and +/-4% on -00) throughout range at 70°F (21 °C)

Temperature Ranges: 2° to 140°F (-7° to 60°C)

Housing Material: Die cast aluminum case and bezel (ABS for P2000), with acrylic cover

Process Connection: 1/8³ female NPT duplicate high and low pressure taps one pair side and one pair back.

Weight: 1 lb 2 oz (510 g)

Accessories: Two 1/8² NPT barbed frftings,two 1/8³ NPT plugs, and three mounting tabs and screws

Warranty: 1 years Approvals: Roi-IS, CE

Reliable Differential Pressure Monitoring

Experience accurate and consistent pressure measurement with the G2000-10MM Magnehelic Gauge. Specially engineered for demanding clean room and HVAC applications, this gauge is built for easy, reliable installation and years of trouble-free service. Its diaphragm sensor offers sensitive detection of low pressure changes, ideal for critical environments and filter performance checks.

Easy Installation and Maintenance

Supplied with two 1/8" NPT female ports and all the necessary mounting accessories, the Galaxy Magnehelic Gauge is ready for rapid installation on vertical surfaces. External zero adjustment simplifies routine maintenance without disassembly, while the clear analog display and sturdy design make it user-friendly for technicians on-site.

Durable Construction and Versatile Application

The G2000-10MM is machined from select acrylic and aluminum materials, ensuring corrosion resistance and longevity. Its industrial-grade specifications make it suitable for a variety of commercial and industrial settingsfrom laboratory environments to large-scale HVAC installationswhere consistent low-pressure monitoring is critical.

FAQs of Galaxy Magnehelic Gauge Model G2000-10MM Range 0-10 MM:

Q: How do I install the Galaxy Magnehelic Gauge Model G2000-10MM?

A: The gauge is designed for quick surface or flush mounting, using the front flange and included mounting screws. Connect high and low pressure lines to the two 1/8" NPT female ports, ensure vertical orientation for accuracy, and use the provided plastic tube adaptors if needed.Q: What environments and applications is this gauge ideal for?

A: This model is well-suited for clean rooms, HVAC systems, filter monitoring, and air or non-corrosive gas flow measurement, especially where monitoring low differential pressure is important. Its robust, industrial-grade build makes it reliable for commercial and laboratory settings.Q: When should I use the zero adjustment feature?

A: The external zero adjustment screw allows you to recalibrate the gauge to compensate for environmental or mechanical shifts. Perform zero adjustment during installation or periodic maintenance, especially if you notice the pointer is off when no pressure difference is applied.Q: Where should I mount the G2000-10MM for optimal performance?

A: Always mount the gauge in a vertical position on a firm, vibration-free surface to ensure measurement accuracy. Its designed for both surface and flush mounting, adaptable to most panel or wall installations in HVAC rooms, laboratories, or process areas.Q: What are the benefits of using a diaphragm sensor in this gauge?

A: A diaphragm sensor ensures precise and sensitive measurement of subtle pressure differences, with minimal mechanical complexity. Unlike bourdon tubes, it provides consistent accuracy (2% of full scale) for low-pressure applications and helps maintain calibration over time.Q: How can I maintain the gauge for long-term use?

A: Routine maintenance involves checking connections for leaks, ensuring the gauge remains vertically mounted, and occasionally resetting the zero point. The durable acrylic and aluminum construction requires only gentle cleaning and protection from harsh chemicals to sustain its appearance and function.Q: What accessories are included with the G2000-10MM Magnehelic Gauge?

A: Each unit comes with mounting screws, two plastic tube adaptors, and a detailed instruction sheet, simplifying installation and initial setup. These accessories help ensure you have everything needed to connect the gauge to your system efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GALAXY MACK TAIBAN USA MAGNEHELIC GAUGE WHOLESALE Category

GALAXY DIFFERENTIAL PRESSURE GAUGE IN Gajipur Industrial Area Faridabad

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Thread : 1/8" female NPT duplicate high and low pressure taps one pair side and one pair back

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Processing Type : Standard

Material : Metal Alloy

GALAXY Differential Pressure Gauge From HAYATPUR INDUSTRIAL AREA GURGAON

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Thread : NPT 1/8 inch

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Processing Type : Standard

Material : Metal Alloy

Galaxy Magnehelic Gauge Model G2000-50MM Range 0-50 MM WC

Price 2600 INR

Minimum Order Quantity : 12 Pieces

Thread : 1/8 NPT Female

Accuracy : 2% of Full Scale

Processing Type : Other, Precision Engineering

Material : Other, Die Cast Aluminum Case

Galaxy Make Magnehelic Gauge

Thread : 1/8 NPT

Accuracy : 2% of Full Scale

Processing Type : Other, Calibrated

Material : Other, Diecast Aluminum Case

Send Inquiry

Send Inquiry