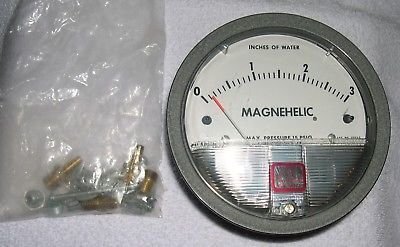

Dwyer USA Magnehelic Gauges 0 To 30 MM WC

Dwyer USA Magnehelic Gauges 0 To 30 MM WC Specification

- Bourdon Tube

- Not Applicable (Capsule Sensing Element)

- Thread

- 1/8 NPT Female

- Sensor Type

- Differential Pressure Sensor

- Display

- Analog Dial

- Grade

- Industrial

- Outer Size

- 109 mm Diameter

- Seal Material

- Silicone Rubber

- Material

- Die-Cast Aluminum Case

- Dial Material

- Aluminum with White Finish

- Pointer Material

- Aluminum

- Processing Type

- Mechanical

- Diameter

- 4 inches (100 mm nominal)

- Glass Size

- 4 inches (100 mm nominal)

- Mount Type

- Surface or Flush Mount

- Scale Range

- 0 to 30 mm WC (Water Column)

- Accuracy

- 2% of Full Scale

- Finishing

- Black Enamel Case Finish

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting Bracket, Screws, Two Pressure Fittings

Dwyer USA Magnehelic Gauges 0 To 30 MM WC Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia, Central America

- Main Domestic Market

- All India

About Dwyer USA Magnehelic Gauges 0 To 30 MM WC

Dwyer USA Magnehelic Gauges 0 To 30 MM WC

INCLUDES

Two 1/8" NPT plugs, two 1/8" rubber tubiSpecifications & Description

ng adapters, and three mounting adapters with screws

MORE ABOUT THIS ITEM

The Magnahelic guage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. The gauge's motion is damped with high-viscosity silicone fluid. The zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness. Rugged design resists shock, vibration, and overpressure.

The helix is precision-made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the maganetic field to move the pointer across the scale. The samarium cobalt magnet is mounted at one end of the range spring and rotates the helix without mechanical linkages.

Specifications & Description

| Accuracy | ±2% full-scale |

| Dial Size (in) | 4 |

| Dial Size (mm) | 102 |

| Min Pressure (in WC) | 0 |

| Max Pressure (in WC) | 10 |

| Wetted Materials | Aluminum |

| Case | Aluminum |

| Lens Material | acrylic |

| Process Connection | 1/8" NPT |

| Unit Of Measurement | " WC |

| Display | analog dial |

| Media Compatibility | Gases and liquids compatible with wetted materials |

| Resolution | 0.20 |

| Description | Magnehelic Differential Pressure Gauge, Type , 0 to 30 MM WC |

Precise Differential Pressure Monitoring

The Dwyer Magnehelic 2000 Series gauge provides accurate measurement of differential pressures from 0 to 30 mm WC, making it an essential tool for applications requiring dependable monitoring. Its capsule sensing element and analog dial ensure clarity and reliability, fitting both routine checks and critical monitoring scenarios in industrial settings.

Built for Durability and Versatility

Encased in die-cast aluminum and finished in black enamel, this industrial gauge resists everyday wear and tear. Its IP54 ingress protection keeps dust and moisture at bay, ensuring steady performance in HVAC, filtration, and cleanroom environments. The unit includes mounting accessories for surface or flush mount installations.

User-Friendly Features and Operational Safety

With clearly labeled high and low pressure ports, an easy-to-read dial, and an external adjustment screw for zeroing, setup and maintenance are straightforward. Its RoHS and CE certifications, along with silicone seals and an aluminum dial, guarantee compliance, safety, and longevity for diverse measurement processes.

FAQs of Dwyer USA Magnehelic Gauges 0 To 30 MM WC:

Q: How do I install the Magnehelic 2000 Series gauge correctly?

A: You can mount the Magnehelic 2000 Series either on a surface or flush with a panel using the provided mounting bracket and screws. Connect the high and low pressure ports using 1/8 NPT female threads to measure the differential pressure accurately. Ensure the gauge is positioned upright and that connection ports align with the intended pressure lines.Q: What types of gases can be measured with this gauge?

A: This gauge is specifically designed to measure air and non-corrosive gases. Use with aggressive or corrosive media is not recommended as it may damage the internal capsule sensing element and seals.Q: When should I perform zero adjustment on this gauge?

A: Zero adjustment should be performed before each use or whenever the gauge is relocated or subjected to vibration. The external adjustment screw makes recalibrating the zero point simple to maintain measurement accuracy.Q: Where is the optimal location to install the Magnehelic gauge for air pressure monitoring?

A: Install the gauge as close as practicable to the sampling point, such as near air filters, fans, or cleanroom partitions, ensuring easy access and minimal pressure drop between the measured zone and the instrument.Q: What benefits does the analog dial display offer over digital versions?

A: The analog dial provides immediate and continuous visual feedback, making it simple to quickly assess pressure changes at a glance. It does not require power, ensuring reliable monitoring even during outages or in low-power environments.Q: How does the overpressure limit enhance the safety and lifespan of the gauge?

A: The Magnehelic 2000 Series supports up to 15 psi continuous overpressure, protecting its internal components against accidental spikes and enhancing both safety and operational life.Q: Is this gauge compliant with industrial safety and environmental standards?

A: Yes, the gauge is both RoHS compliant and CE marked, ensuring adherence to industrial safety, environmental, and quality requirements for use in regulated industrial and commercial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2300-500PA Differential Pressure Gage Range 250-0-250 Pa

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Glass Size : Acrylic Cover, Approx. 124 mm

Processing Type : Other, Molded Plastic Housing

Pointer Material : Other, Black Anodized Aluminum

Finishing : Other, Textured Black Finish Front

Dwyer Magnehelic Differential Pressure Gauge Model 2000-4KPA

Minimum Order Quantity : 12 Pieces

Glass Size : Instrument Front Window ~100 mm

Processing Type : Other, Analog Mechanical Processing

Pointer Material : Other, Black Aluminum

Finishing : Other, Powder Coated/Polished Diecast Aluminum Housing

Dwyer Magnehelic Differential Pressure Gauge Model 2000-1.5KPA

Minimum Order Quantity : 12 Pieces

Glass Size : 4 inch

Processing Type : Other, Precisionengineered

Pointer Material : Other, Fireretardant Polycarbonate

Finishing : Other, Powder Coated Finish

Sensocon Differential Pressure gauge

Glass Size : 110 mm Approx

Processing Type : Other, Mechanical

Pointer Material : Aluminum

Finishing : Other, Powder Coated / Brushed

Send Inquiry

Send Inquiry