Dwyer USA Magnehelic Gauges 0 To 15 MM WC

Dwyer USA Magnehelic Gauges 0 To 15 MM WC Specification

- Thread

- 1/8 NPT

- Display

- Analog Dial

- Outer Size

- Standard Compact Size

- Seal Material

- Silicone Rubber

- Grade

- Industrial Grade

- Sensor Type

- Diaphragm Actuated

- Material

- Die Cast Aluminum (Body), Acrylic (Window)

- Dial Material

- White Aluminum with Black Markings

- Pointer Material

- Black Molded Plastic

- Processing Type

- Mechanical Indication

- Diameter

- 4 Inch (Approx. 100 mm)

- Glass Size

- 4 Inch Clear Acrylic

- Mount Type

- Surface/Flush Mount

- Scale Range

- 0 To 15 MM WC

- Accuracy

- 2% of Full Scale

- Finishing

- Matte Black Case Finish

- Measure Pressure Of

- Low Differential Air/Gas Pressure

- Accessories

- Two self-tapping mounting screws, two 1/8 NPT plugs, two rubber tubing connectors

Dwyer USA Magnehelic Gauges 0 To 15 MM WC Trade Information

- Payment Terms

- Cash on Delivery (COD), Cheque, Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Dwyer USA Magnehelic Gauges 0 To 15 MM WC

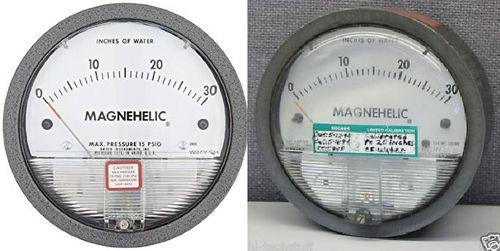

Dwyer USA Magnehelic Gauges 0 To 15 MM WC

INCLUDES

Two 1/8" NPT plugs, two 1/8" rubber tubing adapters, and three mounting adapters with screws

MORE ABOUT THIS ITEM

The Magnahelic guage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. The gauge's motion is damped with high-viscosity silicone fluid. The zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness. Rugged design resists shock, vibration, and overpressure.

The helix is precision-made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the maganetic field to move the pointer across the scale. The samarium cobalt magnet is mounted at one end of the range spring and rotates the helix without mechanical linkages.

Specifications & Description

| Accuracy | ±2% full-scale |

| Dial Size (in) | 4 |

| Dial Size (mm) | 102 |

| Min Pressure (in WC) | 0 |

| Max Pressure (in WC) | 10 |

| Wetted Materials | Aluminum |

| Case | Aluminum |

| Lens Material | acrylic |

| Process Connection | 1/8" NPT |

| Unit Of Measurement | " WC |

| Display | analog dial |

| Media Compatibility | Gases and liquids compatible with wetted materials |

| Resolution | 0.20 |

| Description | Magnehelic Differential Pressure Gauge, Type , 0 to 15 MM WC |

Robust Industrial Design

Designed for demanding environments, the Magnehelic Gauge boasts a die cast aluminum body with a protective coating to resist corrosion and wear. The clear acrylic window ensures the display remains easily readable even in harsh conditions, while the matte black finish offers a professional and durable exterior suitable for industrial use.

Wide Application & High Accuracy

Ideal for measuring low differential air or gas pressures, this gauge is perfectly suited for HVAC systems, clean rooms, filter monitoring, and laboratory environments. The analog dial features a large, clear display, 2% full scale accuracy, and an immediate mechanical response, ensuring you get precise and timely data at a glance.

User-Friendly Installation & Features

The gauge supports both surface and flush mounting options. It comes complete with two self-tapping screws, NPT plugs, and tubing connectors for hassle-free setup. The external zero adjustment knob and side/rear process connections enhance operational flexibility, allowing easy calibration and convenient integration into any monitoring system.

FAQs of Dwyer USA Magnehelic Gauges 0 To 15 MM WC:

Q: How is the Dwyer Magnehelic Gauge 0 to 15 MM WC installed in a monitoring system?

A: Installation is straightforward since the gauge is designed for both surface and flush mounting. It comes with two self-tapping screws, two 1/8 NPT plugs, and two rubber tubing connectors. Process connections are available on both side and rear, making it versatile to fit various system layouts.Q: What benefits does the immediate mechanical response provide in operation?

A: The immediate mechanical response means pressure changes are displayed in real time on the analog dial. This allows operators to quickly identify system performance issues or changes, helping to maintain optimal operating conditions and ensuring prompt corrective action if required.Q: When should I use or select the 0 to 15 MM WC range for measuring differential pressure?

A: Select the 0 to 15 MM WC range when monitoring low differential air or gas pressures, such as in air handling units, filter status monitoring, and clean room environments where sensitive, accurate detection of pressure differences is critical for safety and efficiency.Q: Where can I utilize this industrial grade Magnehelic pressure gauge?

A: This gauge is suitable for use in a variety of locations, such as commercial buildings, HVAC systems, laboratories, clean rooms, and process industries in India and abroad, wherever precise low pressure monitoring is required.Q: What is the process for calibrating the gauge?

A: The gauge comes standardly calibrated at room temperature and in the vertical position. If recalibration is necessary, adjust the external zero adjustment knob to align the dial pointer to zero before use, ensuring highly accurate pressure readings.Q: How does the overpressure protection enhance the gauges safety?

A: Overpressure protection allows the gauge to handle continuous pressures up to 15 psi (1.03 bar) without damage, providing peace of mind and longevity in situations where unexpected system surges may occur.Q: What accessories are included with this Magnehelic gauge for easy setup?

A: The gauge package includes two self-tapping mounting screws, two 1/8 NPT plugs, and two rubber tubing connectors, ensuring you have everything needed for quick, secure installation and integration into your system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer USA Model 2030 Magnehelic Gage Range 0-30 Inch WC

Minimum Order Quantity : 12 Pieces

Outer Size : 41/2 inch (114 mm) diameter

Processing Type : Other, Factory calibrated and leak tested

Glass Size : Approx. 3 inch dia viewing window

Seal Material : Silicone rubber (standard), BunaN (optional)

Accuracy : 2% of full scale

Dwyer 2000-125PA Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Outer Size : 115 mm diameter approx.

Processing Type : Other, Precision Engineered

Glass Size : 104 mm

Seal Material : Silicone Rubber

Accuracy : 2% of full scale

Dwyer 2000-0AV Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Outer Size : 115 mm diameter approx.

Processing Type : Other, Factory calibrated

Glass Size : 4 inches

Seal Material : Silicone rubber

Accuracy : 2% of full scale

Dwyer Magnehelic Differential Pressure Gauge Model 2000-1KPA

Minimum Order Quantity : 12 Pieces

Outer Size : 115 mm approx.

Processing Type : Other, Mechanical

Glass Size : Standard (clear acrylic window)

Seal Material : Silicone and BunaN

Accuracy : 2% of full scale

Send Inquiry

Send Inquiry