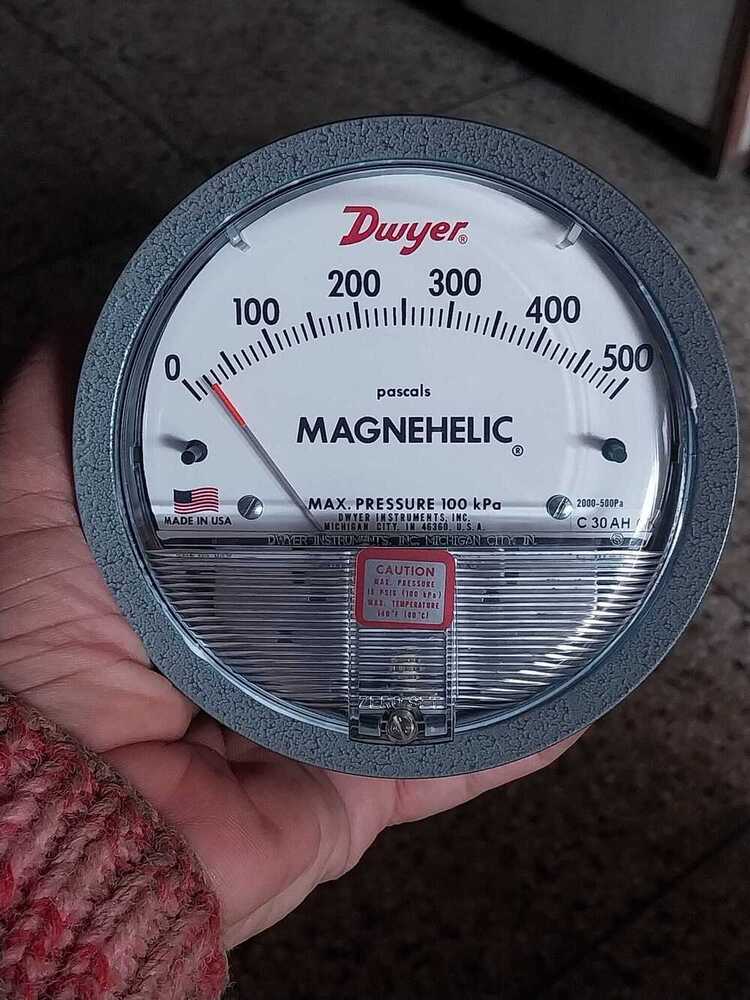

Dwyer USA Magnehelic Gauges 0 To 0.050 Inch WC

Dwyer USA Magnehelic Gauges 0 To 0.050 Inch WC Specification

- Display

- Analog Dial

- Grade

- Industrial

- Seal Material

- Silicone Rubber

- Thread

- 1/8 NPT Female

- Bourdon Tube

- Not Applicable (Diaphragm Sensing Element)

- Outer Size

- 4 inch (101.6 mm) Diameter Housing

- Sensor Type

- Differential Pressure

- Material

- Die-cast Aluminum Case

- Dial Material

- White Aluminum with Black Markings

- Pointer Material

- Black Aluminum

- Processing Type

- Machined Precision

- Diameter

- 4 inches

- Glass Size

- 4 inches

- Mount Type

- Surface or Flush Mounting

- Scale Range

- 0 to 0.050 Inch WC

- Accuracy

- 2% of Full Scale

- Finishing

- Textured Gray Finish Front Bezel

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Bracket, Two Static Pressure Tips, Two 3/16 ID Rubber Tubings (as per model)

Dwyer USA Magnehelic Gauges 0 To 0.050 Inch WC Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

About Dwyer USA Magnehelic Gauges 0 To 0.050 Inch WC

Dwyer USA Magnehelic Gauges 0 To 0.050 Inch WC

| Model | Description |

| 2000-0 | Differential pressure gage, range 0-0.50" w.c., minor divisions .01, calibrated for vertical scale position. |

The industry standard in indicating low air or gas pressures of positive, negative, or differential pressures.

Large, easy-to-read 4" (102 mm) dial.

No manometer fluid to evaporate, freeze, or cause toxic or leveling problems.

INCLUDES

Two 1/8" NPT plugs, two 1/8" rubber tubing adapters, and three mounting adapters with screws

MORE ABOUT THIS ITEM

The Magnahelic guage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. The gauge's motion is damped with high-viscosity silicone fluid. The zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness. Rugged design resists shock, vibration, and overpressure.

The helix is precision-made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the maganetic field to move the pointer across the scale. The samarium cobalt magnet is mounted at one end of the range spring and rotates the helix without mechanical linkages.

Specifications & Description

| Accuracy | ±3% full-scale |

| Dial Size (in) | 4 |

| Dial Size (mm) | 102 |

| Min Pressure (in WC) | 0 |

| Max Pressure (in WC) | 0.5 |

| Min Temperature (° F) | 20 |

| Max Temperature (° F) | 140 |

| Min Temperature (° C) | 7 |

| Max Temperature (° C) | 60 |

| Liquid Fill | Silicone |

| Case | Aluminum |

| Lens Material | Polycarbonate |

| Process Connection | 1/8" NPT(F) |

| Unit Of Measurement | " WC |

| Display | analog dial |

| Media Compatibility | Air and noncombustible, compatible gases |

| Description | Magnehelic Differential Pressure Gauge, 2000: 0-0.5" WC |

Exceptional Sensitivity for Low Pressure Monitoring

This Magnehelic Gauge is specifically engineered for ultra-low-pressure measurement, with a scale range of 0 to 0.050 Inch WC. Its fine-graduated analog dial ensures precise readings, making it perfect for applications that demand high sensitivity, such as HVAC airflow, filter status, and laboratory environments.

Durable Industrial Construction

Crafted with a die-cast aluminum case, machined to precision, and enclosed with a clear acrylic window, this gauge stands up to demanding industrial use. The silicone rubber seal, textured gray bezel, and corrosion-resistant materials ensure longevity and minimal maintenance.

Versatile Mounting and Easy Adjustment

The gauge offers flexible installation, supporting both surface and flush mounting. With both side and optional back connections (1/8" NPT female), adapting to existing setups is straightforward. An external zero adjustment knob allows quick calibration without disassembly, enhancing accuracy and convenience.

FAQs of Dwyer USA Magnehelic Gauges 0 To 0.050 Inch WC:

Q: How do I use the Dwyer Magnehelic Gauge for measuring differential air pressure?

A: To measure differential air pressure, connect the provided static pressure tips to the pressure sources and link them to the gauges side (standard) or back (optional) connections using the included rubber tubing. The analog dial will display the pressure difference in inches WC, allowing for precise monitoring of air and non-corrosive gases.Q: What are the ideal applications for this gauge in industrial settings?

A: This Magnehelic Gauge is ideal for monitoring HVAC system airflows, determining filter performance, controlling cleanroom environments, and checking for proper ventilation in industrial and laboratory facilities where low-pressure measurements are critical.Q: When should the zero adjustment knob be used?

A: The external zero adjustment knob should be used before each new measurement or installation to ensure the gauge reads zero under no pressure condition. This routine calibration maximizes reading accuracy and compensates for any minor mechanical drift.Q: Where should the gauge be installed for optimal accuracy and ease of maintenance?

A: Install the gauge on a stable, vibration-free surface, either in a flush or surface-mounted position, ideally in an area with ambient temperatures between 20F and 140F (-6.7C to 60C). Ensure accessible placement for visual readings and zero adjustment.Q: What process should be followed for safe installation and connection?

A: Secure the mounting bracket and attach the gauge according to the provided instructions. Connect the pressure tips to the source using the included 3/16" ID rubber tubing, ensuring airtight connections. Avoid exceeding the continuous overpressure limit of 15 psi (1.03 bar) to prevent damage.Q: What are the main benefits of using a Magnehelic Gauge over other pressure gauges?

A: The Magnehelic Gauge offers high accuracy (2% of full scale), robust industrial-grade construction, simple installation, and a clear, analog display with fine graduations. Its durability and easy zero adjustment make it a preferred solution for sensitive differential pressure monitoring in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer 2000 Magnehelic Differential Pressure Gage Category

DWYER Magnehelic Air Gauge - Manometer

Accuracy : 2% (HA model 1) of FS (3% (HA 1.5%) on 0, 100PA, 125PA, 10MM and 4% (HA 2%) on 00, 60PA, 6MM Ranges), Throughout Range at 70F (21.1C).

Pointer Material : Alloy

Dial Material : Plastic

Material : Metal Alloy

Processing Type : Standard

Display : Analog

Dwyer USA Magnehelic Gauges 5-0-5 Inch WC

Accuracy : 2% of full scale

Pointer Material : Other, Precision balanced aluminum pointer

Dial Material : Other, White aluminum with black and red markings

Material : Other, Diecast aluminum case, acrylic cover

Processing Type : Other, Factory calibrated and leaktested

Display : Analog

Dwyer USA Magnehelic Gauges 0 To 3.0 Inch WC

Accuracy : 2% of Full Scale

Pointer Material : Aluminum

Dial Material : Other, Acrylic

Material : Other, Cast Aluminum housing

Processing Type : Other, Diecast

Display : Analog

Dwyer USA Magnehelic Gauges 0 To 25 Inch WC

Accuracy : 2% of full scale

Pointer Material : Aluminum

Dial Material : Other, White coated steel

Material : Other, Diecast aluminum case, acrylic lens

Processing Type : Other, Precision calibrated

Display : Analog

Send Inquiry

Send Inquiry