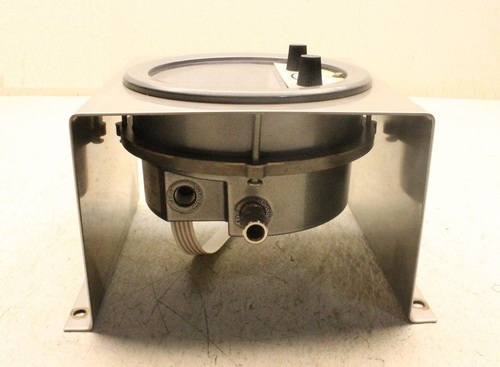

Dwyer 3010MRS Photohelic,Switch/Gauge 0 to 10 in W.C

Dwyer 3010MRS Photohelic,Switch/Gauge 0 to 10 in W.C Specification

- Sensor Type

- Photohelic Switch/Gauge

- Display

- Analog

- Seal Material

- Buna-N

- Thread

- 1/8 NPT Female

- Grade

- Industrial

- Bourdon Tube

- Not Applicable (Diaphragm Sensor)

- Outer Size

- 4 (101.6 mm) Diameter

- Material

- Die Cast Aluminum Case, Acrylic Cover

- Dial Material

- Acrylic

- Pointer Material

- Aluminum

- Processing Type

- Factory Calibrated

- Diameter

- 4 inches (101.6 mm)

- Glass Size

- Clear Acrylic Lens

- Mount Type

- Flush or Surface Mount

- Scale Range

- 0 to 10 in W.C.

- Accuracy

- 2% of Full Scale

- Finishing

- Black ABS Case with Clear Acrylic Cover

- Measure Pressure Of

- Air and Compatible Gases

- Accessories

- Panel Mounting Hardware, Gasket, and Screw Pack

Dwyer 3010MRS Photohelic,Switch/Gauge 0 to 10 in W.C Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Dwyer 3010MRS Photohelic,Switch/Gauge 0 to 10 in W.C

Dwyer 3010MRS Photohelic,Switch/Gauge 0 to 10 in W.C

Pressure switch/gage, range 0-10" w.c., .20 minor divisions.

Model: 3010MRS

Combine the functions of a precise, highly repeatable differential pressure switch with a large easy-to-read analog pressure gauge employing the durable, time-proven Magnehelic gauge design. Versatile electromechanical relays with gold over silver contacts - ideal for dry circuits.

Dwyer 3010MRS Photohelic, Switch/Gauge 0 to 10 in W.C.

Using solid state technology, there Series 3000MR and 3000MRS Photohelic switch/gauges combine the functions of a precise, highly repeatable differential pressure switch with a large easy-to-read analog pressure gage employing the durable, time-proven Magnehelic gage design. Switch setting is easy to adjust with large external knobs on the gage face. Gage reading is unaffected by switch operation - will indicate accurately even if power is interrupted. Solid state design now results in greatly reduced size and weight. Units can be flush mounted in 4-13/16" (122 mm) hole or surface mounted with hardware supplied. 3000MR models employ versatile electromechanical relays with gold over silver contacts - ideal for dry circuits. For applications requiring high cycle rates, choose 3000MRS models with SPST (N.O.) solid state relays. All models provide both low and high limit control and include 18-inch (45 cm) cable assemblies for electrical connections.

Gage accuracy is ±2% of full scale and switch repeatability is ±1%. Switch deadband is one pointer width - less than 1% of full scale. Compatible with air and other non-combustible, non-corrosive gases, they can be used in systems with pressures to 25 psig (1.725 bar).

Reliable Analog Pressure Measurement

The Dwyer 3010MRS provides accurate, reliable pressure readings using a durable diaphragm sensor, perfect for controlling and monitoring differential pressure of air and compatible gases in industrial settings. Its analog display and dual switch functionality ensure real-time pressure monitoring and control without requiring a power supply for gauge operation.

Versatile Mounting and Durable Construction

Supplied with all necessary panel mounting hardware, the 3010MRS can be flush or surface mounted to suit various installation needs. The enclosure, made of die-cast aluminum and fitted with a clear acrylic lens, is designed primarily for indoor use in tough environments, backed by factory calibration to guarantee consistent performance.

Easy Integration and Configurable Set Points

Thanks to its 1/8" NPT female ports and DPDT switch design, integrating the 3010MRS into existing control systems is straightforward. The dual set points allow users to automate processes like alarms or equipment shutdowns when pressure deviates from safe levels, enhancing operational safety and system protection.

FAQs of Dwyer 3010MRS Photohelic,Switch/Gauge 0 to 10 in W.C:

Q: How is the Dwyer 3010MRS Photohelic Switch/Gauge typically installed?

A: The device can be installed either by flush mounting or surface mounting, using the provided panel mounting hardware, gasket, and screw pack. Its 4-inch diameter and 1/8" NPT female pressure connections suit standard panel cutouts and piping.Q: What types of gases or media can be measured with this device?

A: The 3010MRS is specifically designed to measure the pressure of air and compatible gases. It should not be used with liquids or corrosive gases not recommended for Buna-N or acrylic materials.Q: When should the high and low set points be adjusted or used?

A: These set points should be configured based on desired operational thresholds or safety limits. Adjust the high and low points to activate equipment, alarms, or shut down processes when the monitored pressure exceeds or drops below safe values.Q: What environments or applications are best suited for this Photohelic switch/gauge?

A: This instrument is ideal for industrial indoor settings such as HVAC systems, cleanrooms, air handling units, and process control where monitoring and switching on differential air or compatible gas pressure is required.Q: How does the switching mechanism benefit users during operation?

A: The integrated DPDT switches allow automation directly based on pressure changes. This can trigger alarms, ventilation controls, or shutdown equipment, significantly enhancing safety and reducing manual monitoring burden.Q: Does the gauge require an external power supply for operation?

A: No external power is needed for the pressure gauge function. However, power is required for controlling devices wired to the switch outputs, rated for 10A at 120/240/480 VAC.Q: What is the process for routine maintenance of the Dwyer 3010MRS?

A: Routine maintenance generally involves inspecting the pressure connections, ensuring the acrylic lens is clean, and verifying the integrity of seals. Set points should periodically be checked for accuracy and recalibrated if required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer Series 3000MR/3000MRS Photohelic Switch-Gage Category

Dwyer 3015MRS Photohelic,Switch/Gauge 0 to 15 in W.C

Material : Other, Diecast Aluminum Case, Polycarbonate Lens

Accuracy : 2% of Full Scale

Mount Type : Other, Flush or Surface Mount

Glass Size : Full Front Polycarbonate Window

Dial Material : Other, Polycarbonate

Diameter : 4 inches (101.6 mm)

Dwyer 3005MRS Photohelic,Switch/Gauge 0 to 5 in W.C

Material : Other, Diecast aluminum case, polycarbonate lens

Accuracy : 2% full scale

Mount Type : Other, Flush panel mount

Glass Size : 110 mm viewing area

Dial Material : Other, Polycarbonate

Diameter : 142 mm (Approx 5.6 inches)

Dwyer 3000MRS Photohelic Switch/Gauge 0 to 25 MM

Material : Other, DieCast Aluminum Case, Polycarbonate Front Cover

Accuracy : 2% of Full Scale

Mount Type : Other, Flush or Surface Mount

Glass Size : (Approx.) 95 mm Diameter Viewing Window

Dial Material : Other, White Aluminum

Diameter : (Case) 115 mm

Dwyer 3030MRS Photohelic Switch/Gauge 0 to 30 inch

Material : Other, Diecast Aluminum Case

Accuracy : 2% of Full Scale

Mount Type : Other, Surface or Panel Mount

Glass Size : Full Front View

Dial Material : Other, Highimpact Acrylic

Diameter : 41/2 inch (115 mm)

Send Inquiry

Send Inquiry