Differential Pressure Piston-Type Gage

Differential Pressure Piston-Type Gage Specification

- Sensor Type

- Piston-Type

- Seal Material

- Nitrile Rubber

- Outer Size

- 120 mm

- Display

- Analog

- Thread

- 1/2 NPT

- Bourdon Tube

- Not Applicable (Piston-Based)

- Grade

- Industrial

- Material

- Stainless Steel Body

- Dial Material

- Aluminum with Glass Cover

- Pointer Material

- Aluminum

- Processing Type

- Machined

- Diameter

- 120 mm

- Glass Size

- 110 mm

- Mount Type

- Wall Mount

- Scale Range

- 0-1000 mmWC

- Accuracy

- 1% F.S.

- Finishing

- Powder-Coated

- Measure Pressure Of

- Gas, Air, or Non-Aggressive Liquids

- Accessories

- Mounting Brackets, Instruction Manual

Differential Pressure Piston-Type Gage Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Middle East, Africa, Central America, Eastern Europe, South America, Western Europe, Asia, North America, Australia

- Main Domestic Market

- All India

About Differential Pressure Piston-Type Gage

Differential Pressure Piston-Type Gage

Differential Pressure Piston-Type Gage can be used to measure the pressure drop across filters, strainers, pump performance testing, and heat exchanger pressure drop monitoring. Its simple, rugged design possesses weather and corrosion resistant gage front with a shatter resistant lens. The Series PTGD contains a piston-sensing element which provides different differential pressure ranges with full-scale accuracies of ±2%. Constructed with aluminum or 316SS and available with two 1/4" female NPT end connections, the Series PTGD provides over-range protection rated to 3000 psig (200 bar) or 6000 psig (400 bar) depending on model. Standard models come with in-line connections. Back or bottom connections are also available.

Product Applications

Filter pressure drop

Strainers

Pump performance testing

Heat exchanger pressure drop

Differential Pressure Piston-Type Gage can be used to measure the pressure drop across filters, strainers, pump performance testing, and heat exchanger pressure drop monitoring. Its simple, rugged design possesses weather and corrosion resistant gage front with a shatter resistant lens. The Series PTGD contains a piston-sensing element which provides different differential pressure ranges with full-scale accuracies of ±2%. Constructed with aluminum or 316SS and available with two 1/4" female NPT end connections, the Series PTGD provides over-range protection rated to 3000 psig (200 bar) or 6000 psig (400 bar) depending on model. Standard models come with in-line connections. Back or bottom connections are also available.

Product Applications

Filter pressure drop

Strainers

Pump performance testing

Heat exchanger pressure drop

Industrial-Grade Durability

Constructed with a corrosion-resistant stainless steel body, this differential pressure gauge is designed for long service life in challenging industrial settings. The powder-coated finish and IP54 ingress protection offer robust resistance against dust and water. Machined to precision and equipped with a toughened glass window, it ensures clear readings and operational safety in demanding environments.

Effortless Installation and Operation

Equipped with a bottom 1/2 NPT connection and wall-mount design, this gauge suits both new installations and replacements in HVAC and process monitoring. The supplied mounting brackets and instruction manual make setup straightforward for technicians. Its piston-based sensor system, paired with analog display, enables instant pressure readings with minimal maintenance requirements and no need for external power.

Wide Application Versatility

Designed for measuring differential pressure in air, water, and other non-aggressive fluids, this gauge finds use in filter monitoring, HVAC systems, and industrial flow measurement. Its quick response time enables prompt system checks, and the 1% F.S. accuracy supports rigorous monitoring. Manufacturing, processing, and utility facilities benefit from this robust and precise measuring instrument.

FAQs of Differential Pressure Piston-Type Gage:

Q: How does the piston-type sensor in this differential pressure gauge operate?

A: The piston-type sensor utilizes a machined piston and a nitrile rubber seal to translate pressure differences into mechanical displacement, moving the analog pointer. This mechanism delivers accurate and rapid readings, making it suitable for applications that require reliable differential pressure monitoring.Q: What media can be safely measured with this gauge?

A: This differential pressure gauge is designed to measure air, gas, water, and non-aggressive liquids. It should not be used with corrosive or aggressive fluids, ensuring longevity and performance within its intended application, such as HVAC and filter systems.Q: When is overload protection utilized, and what is its specified rating?

A: Overload protection engages if the pressure surpasses the 1000 mmWC scale limit, safeguarding internal components from damage. This model can safely withstand transient pressures up to 150% of the maximum scale, preserving accuracy and integrity in demanding operational environments.Q: Where should this gauge be installed for optimal performance?

A: For best results, the gauge should be wall-mounted using the provided brackets, and connected at the bottom 1/2 NPT port. Installation should be in a location where the ambient temperature remains between -10C and +60C, and the unit is protected from direct water jets or corrosive atmospheres.Q: What are the primary benefits of using this gauge in industrial applications?

A: Key benefits include high accuracy (1% F.S.), rapid response (<2 seconds), and excellent durability due to corrosion-resistant materials and IP54 ingress protection. The analog display is easily readable, while the robust construction supports reliable operation in harsh settings.Q: How do I process and maintain the gauge to ensure long-term accuracy?

A: Routine visual inspections and periodic cleaning of the toughened glass and stainless-steel case are recommended. Ensure the gauge is used only with compatible media and that pressure levels remain within specified limits. No special recalibration tools are needed; refer to the supplied instruction manual for further maintenance guidance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

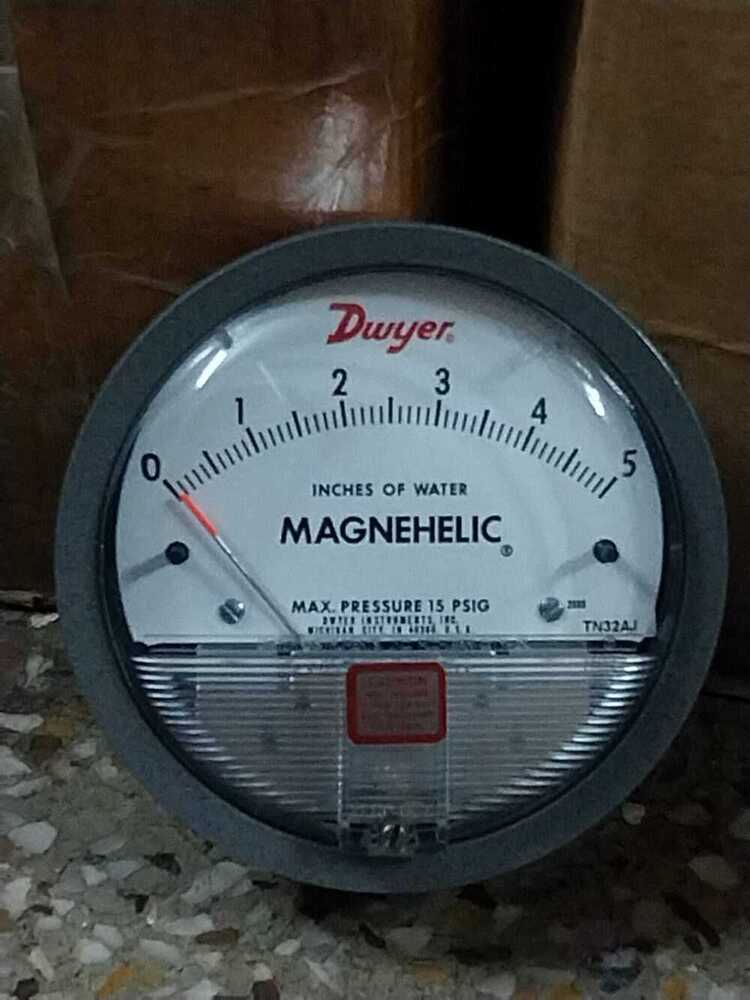

More Products in Dwyer Sensocon USA Magnehelic Gauge wholesaler Category

Dwyer Magnehelic Gauge In Beed Maharashtra

Price 5800.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal Alloy

Thread : NPT 1/8 inch

Processing Type : Standard

Diameter : 4 inch / 100 mm

DWYER Magnehelic Gauge From Baikampandy Industrial Area Karnataka

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal Alloy

Thread : NPT 1/8 inch

Processing Type : Standard

Diameter : 4 inch / 100 mm

DWYER Magnehelic Gauge From Karnad Industrial Area Karnataka

Price 7500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal Alloy

Thread : NPT 1/8 inch

Processing Type : Standard

Diameter : 4 inch / 100 mm

Series PTGB Differential Pressure Piston-Type Gage

Material : Other, Aluminum Body, Brass Wetted Parts

Thread : 1/8 NPT

Processing Type : Other, Machined Housing

Diameter : 96 mm

Send Inquiry

Send Inquiry