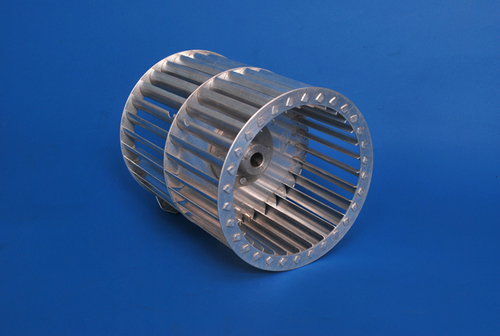

DIDW Centrifugal Fan 280 MM X 305 MM

DIDW Centrifugal Fan 280 MM X 305 MM Specification

- Efficiency

- 70-75%

- Air Flow

- Up to 3050 m3/h

- Temperature

- Up to 60C

- Orientation

- Double Inlet Double Width

- Power Source

- Electric

- Instruments Type

- Blower/Fan

- Usage & Applications

- Industrial ventilation, Air handling units, HVAC systems

- Automation Grade

- Manual

- Measurement

- Air Volume

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooling

- Noise Level

- Less than 80 dB

- Processing Time

- Continuous

- Capacity

- Up to 1800 CFM

- Voltage

- 230 V

- Weight

- Approx. 45 Kg

- Dimension (L*W*H)

- 280 mm x 305 mm

- Surface

- Powder coated

DIDW Centrifugal Fan 280 MM X 305 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 280 MM X 305 MM

DIDW Centrifugal Fan 280 MM X 305 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 47 | ETIP 11 12 | 280 X 305X 236 | 11 X 12 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Durable Mild Steel Construction

Designed with high-quality mild steel and a protective powdered coating, the DIDW Centrifugal Fan withstands demanding conditions and resists corrosion, extending service life. The robust frame maintains strength during continuous and heavy-duty operation, making it ideal for industrial air management.

Efficient Air Moving Performance

This fan utilizes a forward curved, 16-blade impeller, maximizing airflow and efficiency (7075%). Operating quietly below 80 dB, it moves substantial air volume at up to 1800 CFM, suiting large industrial spaces while maintaining comfortable noise levels.

Applications Across Industry Segments

The DIDW Centrifugal Fan fits into numerous settings, such as air handling units, HVAC systems, and industrial ventilation. It functions efficiently in environments with temperatures up to 60C, offering reliable air movement and cooling in manufacturing facilities, warehouses, and processing plants.

FAQs of DIDW Centrifugal Fan 280 MM X 305 MM:

Q: How is the DIDW Centrifugal Fan installed in industrial setups?

A: Installation is straightforward thanks to its base-mounted and flange mount connection design. The fan can be securely fixed to the floor or a mounting platform, and connected to the ductwork using flanges, ensuring stable operation and ease of integration into air handling systems.Q: What types of environments benefit most from this centrifugal fan?

A: This fan is ideal for industrial ventilation, HVAC systems, and air handling units in factories, warehouses, and processing plants. Its continuous operation, high air volume capacity, and mild steel construction make it suited for demanding conditions with ambient temperatures up to 60C.Q: When should maintenance be performed on the DIDW Centrifugal Fan?

A: Routine maintenance is recommended at regular intervalstypically every three to six months, depending on usage and application. Check the belt drive, impeller, and motor for wear, clean accumulated dust, and inspect the powder coating for any signs of corrosion to ensure optimal performance.Q: Where can this fan be purchased or sourced in India?

A: You can obtain the DIDW Centrifugal Fan through authorized manufacturers, suppliers, traders, and wholesalers across India. Availability from multiple channels ensures accessibility for industrial customers and project requirements nationwide.Q: What process is involved for controlling air flow with the fan?

A: Air flow is manually regulated via control instruments and belt-driven speed adjustments. Operators can adjust ductwork openings or modify belt tension as needed to optimize air volume and static pressure, adapting to the specific requirements of the system.Q: What are the main advantages of using this fan over alternative models?

A: Key advantages include robust mild steel construction with powder coating for durability, high airflow (up to 1800 CFM), efficient forward curved impeller design, low noise levels, and flexibility in industrial settings. The manual automation grade adds reliable hands-on control for tailored ventilation needs.Q: Can the fan handle continuous processing and prolonged operation?

A: Yes, the DIDW Centrifugal Fan is built for continuous operation. Its air-cooled motor and efficient belt-driven system allow it to run for extended periods without overheating, making it suitable for 24/7 processing requirements in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 530 MM X 380 MM

Price 17000 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Voltage : 415 V

Cooling System : Other, Air Cooled

Material : Mild Steel

DIDW Centrifugal Fan 300 MM X 203 MM

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Product Type : Double Inlet Double Width (DIDW) Centrifugal Fan

Voltage : 415 V AC

Cooling System : Other, Air Cooled

Material : Mild Steel (MS)

DIDW Centrifugal Fan 140 MM X 150 MM

Price 800 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Voltage : 220240 V

Cooling System : Air Cooling

Material : Mild Steel

DIDW Centrifugal Fan 250 MM X 150 MM

Price 2000 INR

Minimum Order Quantity : 12 Pieces

Product Type : Double Inlet Double Width (DIDW) Centrifugal Fan

Voltage : 220415 V

Cooling System : Other, Air Cooled

Material : Mild Steel

Send Inquiry

Send Inquiry