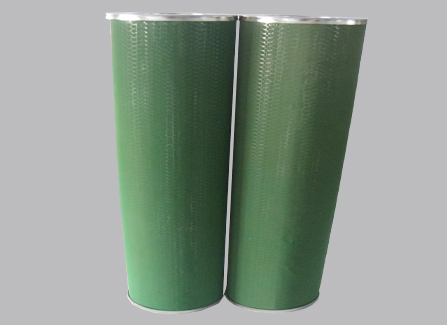

Cylindrical Filters From High Quality Air Filters

Cylindrical Filters From High Quality Air Filters Specification

- Cleaning Method

- Compressed air, Washing

- Pressure

- 0.2 bar max

- Flow Rate

- 500 to 5000 m/h (based on model)

- Filter Type

- Air Filter

- Filtration Grade

- Medium, Fine

- Temperature Range

- -20C to 80C

- Connecting Type

- Flange/End cap

- Media Type

- Nonwoven synthetic, Cellulose

- Capacity

- High dust load capacity

- Efficiency (%)

- Up to 99%

- Condition

- New

- Material

- Galvanized steel, Synthetic fiber, Paper, Stainless steel

- Mesh

- Available in various mesh sizes

- Diameter

- 100 mm to 400 mm (customizable)

- Construction

- Pleated, Cylindrical

- Medium Filter

- Synthetic fiber/Paper

- Weight

- 1 kg to 4 kg (depending on size)

- Shape

- Cylindrical

- Feature

- High dust holding capacity, Durable, Easy to install, Low pressure drop

Cylindrical Filters From High Quality Air Filters Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Middle East, Western Europe, Central America, Africa, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Cylindrical Filters From High Quality Air Filters

Cylindrical Filters From High Quality Air FiltersThe Cylindrical Cartridge Filter can be used in virutually all industries such as powder coating/powder paint, sand blasting, woodworking, welding, metals and many others. It is a common filter found in many vertical and horizontal dust collectors as well as downdraft tables.

Categories: Air Filter, Dust Collector Tags: air filter, dust collector

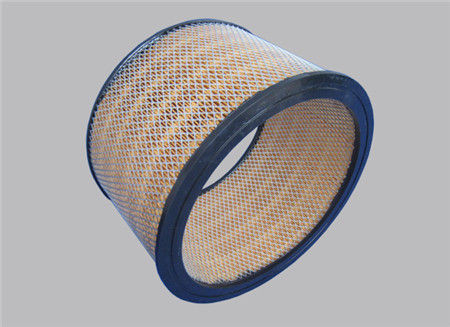

Comprehensive Filtration Performance

These cylindrical filters are designed to capture airborne particles as small as 0.3 microns, offering versatile filtration in settings demanding clean air. The pleated, cylindrical design maximizes surface area for dust retention, ensuring robust operation even in high-load environments such as compressor air intakes, exhaust systems, and clean rooms.

Adaptable Design for Various Applications

With a customizable diameter, selection of end cap materials, and multiple mesh sizes, the filters fit seamlessly into diverse industrial setups. Compatible with media options like nonwoven synthetic, cellulose, and galvanized mesh, they cater to unique process requirements and can handle flow rates from 500 to 5000 m/h.

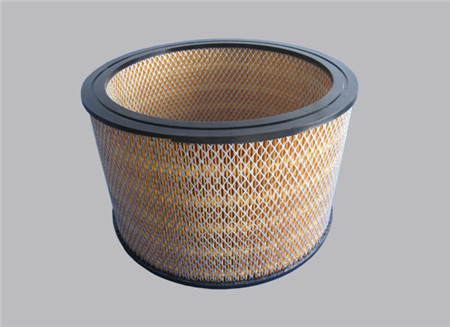

Durability and Easy Maintenance

Engineered for longevity, the filters feature anti-corrosive treatments and sturdy construction. Maintenance is simple: clean using compressed air or washing. For optimal performance, replacement is recommended every 612 months, minimizing downtime and maximizing efficiency.

FAQs of Cylindrical Filters From High Quality Air Filters:

Q: How are cylindrical filters from High Quality Air Filters used in industrial environments?

A: These filters are primarily used in industrial HVAC systems, dust collection units, air purification setups, and ventilation ducts. Their ability to remove particles down to 0.3 microns makes them suitable for compressor air intake, exhaust applications, and clean room environments.Q: What materials are available for the construction of these cylindrical filters?

A: The filters can be constructed from a variety of materials including galvanized steel, stainless steel, synthetic fiber, cellulose, and filter paper. End caps are available in mild steel, plastic, or stainless steel, and the mesh comes in various sizes to suit specific filtration needs.Q: When should cylindrical filters be replaced for optimal performance?

A: It is recommended to replace these filters every 6 to 12 months depending on environmental conditions and dust load. Regular replacement helps maintain high filtration efficiency and prevent system pressure drop.Q: Where can these filters be installed and what is their mounting flexibility?

A: Cylindrical filters can be installed in both vertical and horizontal orientations, making them adaptable to different system configurations in industrial and commercial environments.Q: What is the cleaning process for cylindrical filters?

A: Cleaning the filters typically involves either compressed air blowback or washing, depending on the media type. This helps prolong filter life and maintain throughput before eventual replacement.Q: What are the main benefits of using these cylindrical filters in air systems?

A: Key benefits include high dust holding capacity, durability, low pressure drop leading to energy savings, and easy installation. These qualities make them reliable for maintaining superior air quality and operational efficiency in various applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

Replacement Filter Element

Price 3000 INR / Piece

Minimum Order Quantity : 12

Material : Stainless Steel

Condition : New

Feature : High dirt holding capacity, precise filtration, long service life

Media Type : Other, Liquid / Gas

Oil Water Separator From Coalescer and Separator

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel, Mild Steel (option available)

Condition : New

Feature : Efficient separation of oil and water using coalescer and separator element design

Media Type : Other, Coalescing and separating elements

F5 Bag Filter From High Quality Air Filters

Minimum Order Quantity : 12 Pieces

Material : Synthetic Fiber

Condition : New

Feature : High dust holding capacity, Low initial resistance, Good air permeability

Media Type : Other, Microfine synthetic media

Taisei Kogyo Hydraulic Filter Hydraulic Oil Filters

Minimum Order Quantity : 12 Paints

Material : Stainless Steel/Glass Fiber/Paper

Condition : New

Feature : High dirtholding capacity, reliable filtration, long service life, easy installation and replacement

Media Type : Other, Glass Fiber, Paper, Stainless Steel Mesh

Send Inquiry

Send Inquiry