Cellulose Cooling Pad

Cellulose Cooling Pad Specification

- Application

- Air coolers, HVAC systems, greenhouses, poultry farms

- Coverage Area

- Depends on pad size and air flow

- Humidity Range

- 60% - 95%

- Power Source

- Works passively, not powered

- Automation Grade

- Manual

- Features

- High efficiency evaporation; long life; low maintenance

- Accessories

- Frame, fixers, water distribution pipe

- Noise Level

- Silent operation

- Technology

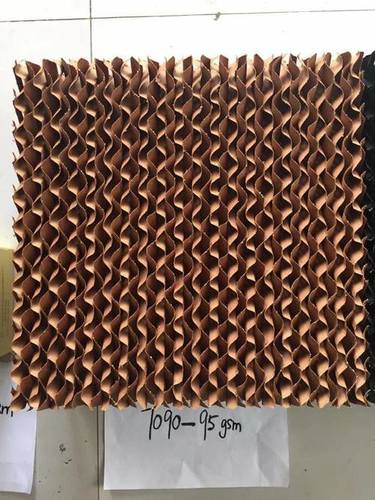

- Cross corrugated design

- Shape

- Rectangular

- Mounting Type

- Frame mounting, suitable for air coolers

- Filtration Property

- Removes dust and particulate contaminants

- Surface Finish

- Smooth surface

- Energy Efficiency Rating

- Energy efficient

- Air Flow Capacity

- High

- Material

- Cellulose Paper

- Type

- Evaporative Cooling Pad

- Capacity

- High water absorption capacity

- Installation Type

- Easy to install; can be mounted vertically or horizontally

- Usage

- Industrial and Commercial

- Function

- Air cooling, humidification

Cellulose Cooling Pad Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Western Europe, Middle East, Africa, South America, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About Cellulose Cooling Pad

Cellulose Cooling Pad

Cellulose Cooling Pad Apart form manufacturing the fans for various applications, Enviro Tech make the Cellulose Pad, made by these Thailand and Italy various companies in India and are well established with respect to Poultry, Horticulture (Green House) and Industrial applications. The Evaporative Cooling Pad (ECP), made of cellulose paper is engineered from cross-sectional, specially treated flute media capable of absorbing and retaining water to provide the maximum cooling efficiencies. The cellulose media is treated with stiffening and wetting agents to provide the cooling without any water carryover. The pads are designed for tropical and subtropical countries, ensures greatest performance during summer seasons. Mixed Esters of Cellulose (MCE) or Cellulose Acetate (CA) is best for microbiology and environment monitoring test. Contrasting grid lines facilitate counting colonies on the filter surface and are tested to assure freedom from grid line inhibition. The Membrane Solutions MCE membranes are also tested for freedom from grid line inhibition and optimal color reactions on appropriate test media. Features The Cellulose Pad is cross corrugated coated with anti rot, rigidify & wetting resins. The 150 VAPUR Pad are made for maximum efficiency, at minimum pressure drop.The pad media is treated with anti-rot and rigidify resins. The media is cross-corrugated to maximize the mixing of air and water. Saturation efficiency ranging from 50 to 98% can be achieved depending upon air velocity and depth of the cooling pad. Air flows horizontally, while the re-circulating water flows vertically, through the pad. The water is collected at bottom of the pad and is re-circulated, again by a pump through the unique gutter system made of G. I. Sheet. Availability:- Absorbent Pads Sterile Mixed Cellulose Ester (MCE) filter Petri Dishes Sterile Cellulose Acetate Filter Application:- Enviro Tech make Evaporative Cooler system this system is efficiently backed up by the cellulose pads that in turn amplifies the efficiency of the system on a whole and thus provides cooler air in the required area. Waste-water, Microbiological analysis of water, beverages. Quartz fiber filter for monitoring air pollution. Thimble filters for monitoring dust, organic, metal, or other pollutants. Small volume field sampling and analysis of fluids or aerosols

Efficient and Sustainable Cooling Solution

Designed for modern air cooling, these cellulose pads feature a high-efficiency evaporation process, utilizing a unique cross-corrugated cellulose structure. The result is reliable cooling, energy savings, and a healthier indoor environment, all with minimal maintenance requirements. Their fully recyclable composition and long lifespan make them an environmentally conscious choice for various industrial, commercial, and agricultural operations.

Customizable for Diverse Applications

These cooling pads can be tailored in thickness, height, and width to fit a wide range of air cooling systems, from air coolers to large-scale HVAC units and greenhouse setups. With robust resistance to fungi and algae, they remain effective through years of demanding operation, even at working temperatures up to 65C. The smooth surface finish complements easy cleaning and frame mounting for simplified installation.

FAQs of Cellulose Cooling Pad:

Q: How do cellulose cooling pads function in air coolers and HVAC systems?

A: Cellulose cooling pads work by allowing warm air to pass through their water-saturated cross-corrugated structure, which absorbs heat and lowers the air temperature. This process provides efficient cooling and humidification in air coolers, HVAC systems, greenhouses, and poultry farms.Q: What are the advantages of using these cooling pads over conventional alternatives?

A: These pads offer several benefits: high energy efficiency due to passive operation, excellent water absorption, silent air flow, robust resistance to fungi and algae, and a long service life. Their recyclable nature and low water consumption make them a sustainable and economical option for industrial and commercial cooling.Q: Where can I install cellulose cooling pads?

A: The pads are suitable for installation in a variety of locations including air coolers, HVAC systems, agricultural greenhouses, and poultry sheds. They can be mounted vertically or horizontally using a frame, adapting easily to different layouts and requirements.Q: What is the process for installing these cooling pads?

A: Installation is straightforward: simply fit the pad into the mounting frame provided, connect the water distribution pipe, and secure it with the included fixers. No electrical power is required as the pad operates passively, relying on water flow and air movement.Q: When should I replace the cooling pads for optimal performance?

A: To maintain optimal performance and air quality, it is recommended to replace the pads every 3 to 5 years, depending on water quality and local environmental conditions. Regular cleaning can also help extend the service life.Q: What customization options are available for these pads?

A: You can choose from standard thicknesses (100mm, 150mm) and pad dimensions, or request custom sizes to fit unique requirements. This ensures maximum compatibility for your air cooling or HVAC system.Q: How do cellulose pads improve indoor air quality?

A: Their filtration properties effectively capture dust and particulate matter from the incoming air, resulting in cleaner, fresher indoor environments. This makes them particularly suitable for sensitive applications like poultry farms or greenhouse cultivation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Washer Cooling Pad Wholesale Suppliers India Category

Enviro Tech Cooling Pad

Application : Air Coolers, HVAC, Greenhouses, Poultry Farms

Function : Other, Air Cooling & Humidification

Capacity : High Water Retention

Automation Grade : Manual

Features : High Evaporation Efficiency, Long Lifespan, Resistant to Mold & Algae

Coverage Area : Depends on Cooler Size (standard 6001200 sq.ft./pad)

Yellow Green Evaporative Cooling Pad

Application : HVAC Systems, Agriculture, Poultry, Greenhouses

Function : Other, Air Cooling through Evaporation

Capacity : High Water Retention Capacity

Automation Grade : Manual

Features : YellowGreen Color, High Durability, Uniform Wetting, Antimildew, EcoFriendly

Coverage Area : Customizable as per Requirement

Water Retention Pads

Application : Cooling, Humidification, Air Scrubbing

Function : Other, Water Retention for Cooling, Humidification

Capacity : High Moisture Absorption

Automation Grade : Manual/Automatic Compatible

Features : High Water Absorption, Long Life, Uniform Cooling

Coverage Area : Depends on Pad Dimensions

8 inch Rigid Media Pad

Application : Air Coolers, HVAC Systems

Function : Other, Evaporative Cooling

Capacity : High Water Absorption

Automation Grade : Manual

Features : Long Life, Antimicrobial, High Water Retention

Coverage Area : Up to 600 sq.ft.

Send Inquiry

Send Inquiry