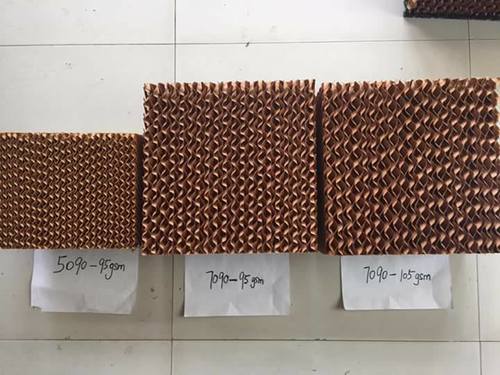

Water Retention Pads

Water Retention Pads Specification

- Application

- Cooling, Humidification, Air Scrubbing

- Technology

- Multi-layer Corrugated Sheet

- Air Flow Capacity

- Optimal, High Permeability

- Noise Level

- Silent Operation

- Filtration Property

- Dust and Debris Filter

- Accessories

- Nozzle, Bracket (As per installation)

- Energy Efficiency Rating

- Eco-friendly, Energy Saving

- Automation Grade

- Manual/Automatic Compatible

- Humidity Range

- 60% - 90%

- Features

- High Water Absorption, Long Life, Uniform Cooling

- Surface Finish

- Smooth, Anti-bacterial Coated

- Shape

- Rectangular

- Coverage Area

- Depends on Pad Dimensions

- Mounting Type

- Side/Frame Mountable

- Material

- Cellulose and Kraft Paper

- Type

- Water Retention Pad

- Capacity

- High Moisture Absorption

- Installation Type

- Panel/Fitting Mount

- Usage

- Evaporative Cooling Systems, Greenhouses, Poultry Farms

- Function

- Water Retention for Cooling, Humidification

Water Retention Pads Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Middle East, Africa, Central America, Eastern Europe, South America, Western Europe, Asia, North America, Australia

- Main Domestic Market

- All India

About Water Retention Pads

Water Retention Pads

Water Retention Pads (Cellulose Pads) work on asimple principle of cooling with the help of water. water flow from top to bottom of the pad and the air is sucked through the cellulose where the air cools down with the help of water, thus the warm air cools down and thus cools the temperature inside the greenhouse.

Specifications:

- Thickness: 1.5mm

- Power Line: Silicone Wire

- Voltage: 12V

- Application: Heater

Advanced Water Retention Technology

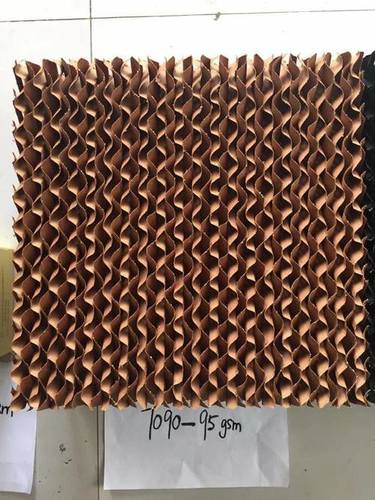

Featuring a unique multi-layer cross-corrugated structure, our pads maximize water absorption and distribution, resulting in consistent and effective cooling. This design not only ensures uniform moisture retention but also enhances filtration, helping maintain a clean and efficient system in demanding environments.

Customizable for Diverse Applications

Our pads can be tailored in thickness, height, and width to fit various installation needs, making them suitable for greenhouses, poultry farms, and industrial cooling systems. With multiple colors and mounting options, they integrate seamlessly into existing setups while delivering dependable performance.

Durable, Eco-Friendly, and Efficient

Constructed from premium cellulose and kraft paper, these pads are not just robustthey are also environmentally responsible. With an anti-bacterial coating and up to 85% water retention efficiency, they ensure long-lasting, hygienic operation while contributing to energy savings and reduced maintenance needs.

FAQs of Water Retention Pads:

Q: How are Water Retention Pads installed for maximum efficiency?

A: Water Retention Pads are typically installed using panel or frame mounting systems, depending on your specific requirements. Secure placement ensures optimal airflow, uniform water distribution, and efficient cooling or humidification in your facility.Q: What types of environments are best suited for these pads?

A: These pads are ideal for environments needing high moisture control, like evaporative cooling systems, greenhouses, and poultry farms. They also perform well in air scrubbing and humidification applications, handling humidity ranges between 60% and 90%.Q: When should Water Retention Pads be replaced to maintain performance?

A: Under normal usage conditions, its recommended to replace the pads every 35 years. Factors such as water quality, exposure to dust, and frequency of use may affect this interval. Regular inspection helps prolong their effectiveness.Q: What is the benefit of the cross-corrugated structure in these pads?

A: The cross-corrugated structure increases the effective surface area for water absorption, ensuring even evaporation and efficient cooling or humidification. This design also aids in filtering dust and debris for cleaner air output.Q: Where can I use these Water Retention Pads?

A: You can use these pads in a range of settings, including greenhouses, poultry houses, industrial cooling systems, and wherever efficient moisture management and air-cleaning are required.Q: How do the materials and anti-bacterial coating contribute to pad longevity?

A: High-quality cellulose and kraft paper materials, combined with an anti-bacterial coating, resist degradation and microbial growth, promoting a longer lifespan and maintaining hygiene throughout use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Washer Cooling Pad Wholesale Suppliers India Category

Industrial Air Cooling Pad

Technology : Cellulose Honeycomb Technology

Application : Factory, Warehouse, Agriculture, Poultry Farm

Material : Other, Cellulose Paper

Filtration Property : Dust and Particulate Filtering

Accessories : Aluminum/Plastic Frame, Water Distribution Pipe

Function : Other, Air Cooling Via Evaporation

Enviro Tech Cooling Pad

Technology : Advanced Corrugated Structure

Application : Air Coolers, HVAC, Greenhouses, Poultry Farms

Material : Other, Specially Engineered Cellulose Paper

Filtration Property : Filters Dust & Particulates

Accessories : Pad Frame, Water Distribution System

Function : Other, Air Cooling & Humidification

ChillCel Cellulose Pad

Technology : Evaporative Cooling

Application : Air Coolers, HVAC, Greenhouses, Poultry Farms

Material : Other, Cellulose Paper

Filtration Property : Dust Filtration

Accessories : Framing, Water Distribution Pipe

Function : Other, Air Cooler Media

Cooling Wall Pad

Technology : Evaporative Cooling

Application : Agricultural/Industrial Cooling

Material : Other, Cellulose Paper

Filtration Property : Water Filtration Capability

Accessories : Water Distribution System, Frame

Function : Other, Air Cooling and Humidification

Send Inquiry

Send Inquiry