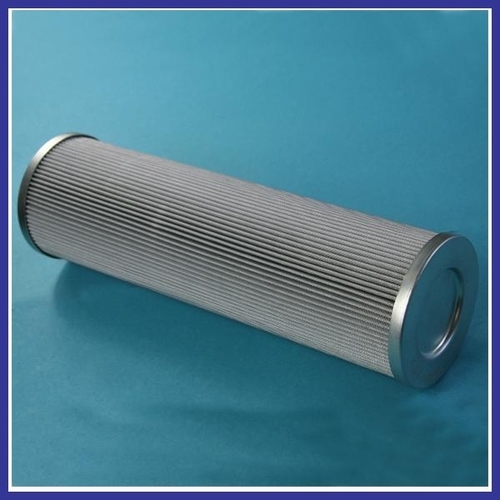

Argo Hydraulic Oil Filter

Argo Hydraulic Oil Filter Specification

- Pressure

- Max 21 bar

- Filter Type

- Hydraulic Oil Filter

- Flow Rate

- 50-250 l/min (variant specific)

- Efficiency (%)

- Up to 99%

- Connecting Type

- Threaded/Flanged end

- Filtration Grade

- Fine to ultra-fine

- Temperature Range

- -20C to +120C

- Capacity

- High contaminant retention

- Cleaning Method

- Disposable or washable (model dependent)

- Media Type

- Microglass fiber, Stainless steel

- Condition

- New

- Material

- Stainless Steel, Glass Fiber, Cellulose Paper

- Mesh

- Fine mesh (micron rating obtainable on request)

- Diameter

- Standard sizes or customizable

- Construction

- Heavy-duty cylindrical pleated design

- Medium Filter

- Hydraulic oil

- Weight

- Approx. 700-1100 grams

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, Durable construction

Argo Hydraulic Oil Filter Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Paypal, Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Argo Hydraulic Oil Filter

Argo Hydraulic Oil FilterPlease note all the replacement Argo series oil filter and oil filter elements are produced by us whose quality are great enough to meet your requirement meanwhile own very competitive price which can be used well to replace Argo oil filter and oil filter elements that produced by Argo. Please contact Argo directly in case you need Argo original produced oil filter and oil filter elements.

Categories: Replacement Filter Series, Argo Oil Filter Tags: Oil Filter Element, Argo Oil Filter, Argo Hydraulic Oil Filter, Argo Filter

Advanced Construction & Materials

Argo Hydraulic Oil Filters utilize a blend of stainless steel, glass fiber, and cellulose paper to create a heavy-duty cylindrical filter with pleated design. The robust end caps in galvanized steel or aluminum enhance durability, while specialized seals in either Nitrile/Buna-N or Viton provide reliable leak resistance, even under challenging operational conditions.

Versatile Performance & Application

Designed for both mobile and industrial hydraulic systems, this filter supports standard and customizable diameters, various flow rates, and both vertical and horizontal mounting. Compatible with multiple OEM brands, it is ideal for a wide array of hydraulic equipment utilized in manufacturing, construction, and industrial sectors.

Optimized Efficiency & Longevity

With a filtration efficiency up to 99% and high contaminant retention, the Argo Hydraulic Oil Filter ensures extended service intervals and reduced equipment downtime. Its working life of up to 1000 hours (application dependent) and adherence to ISO 16889 standards guarantee long-lasting, dependable performance for rigorous operational demands.

FAQs of Argo Hydraulic Oil Filter:

Q: How should the Argo Hydraulic Oil Filter be installed in my hydraulic system?

A: The Argo Hydraulic Oil Filter is designed for straightforward installation, supporting both vertical and horizontal mounting orientations. Ensure compatibility with your hydraulic systems specifications and follow OEM or equipment manuals for installation procedures. Threaded or flanged connections are available, depending on the model.Q: What are the benefits of using the Argo Hydraulic Oil Filter in industrial environments?

A: Using the Argo Hydraulic Oil Filter enhances equipment longevity by capturing up to 99% of contaminants. Its durable construction, high dirt holding capacity, and ISO 16889 compliance help prevent costly breakdowns, improve operational efficiency, and minimize maintenance needs.Q: When should I replace or clean the Argo Hydraulic Oil Filter?

A: Filter replacement or cleaning should follow the original equipment manufacturers maintenance schedule or as dictated by system conditions. The working life can extend up to 1000 hours, but factors such as usage intensity and contamination levels may influence the interval. Some models are washable; others are disposable.Q: What hydraulic systems are compatible with this oil filter?

A: The Argo Hydraulic Oil Filter is suitable for a variety of mobile and industrial hydraulic systems. It is compatible with multiple OEM brands and available in standard or customizable sizes to match diverse hydraulic equipment applications across industries.Q: Where is the Argo Hydraulic Oil Filter manufactured and supplied?

A: These filters are manufactured, supplied, and distributed across India. They are available through authorized suppliers, traders, and wholesalers, supporting both replacement and original equipment needs throughout the country.Q: What is the recommended filtration grade and can I request a specific micron rating?

A: The filter offers fine to ultra-fine filtration grades, supporting high contaminant retention and efficiency. Yes, you can request specific micron ratings according to your systems needs, enabling precise oil cleanliness for sensitive equipment.Q: How does the integrated bypass valve option benefit hydraulic systems?

A: The integrated bypass valve (optional) ensures oil flow continues in case of excessive clogging or high differential pressure, protecting hydraulic components from damage due to flow restriction and maintaining consistent operation, especially in critical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

PALL Filter Cartridge From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Filter Type : Return line / pressure line filter cartridge

Construction : Other, Pleated cartridge

Feature : High dirt holding capacity, excellent filtration efficiency, low pressure drop

Mesh : Customizable (typically 1060 micron)

Flow Rate : 120 3500 LPH (Liters per hour) depends on model

HYDAC High Pressure Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Filter Type : High Pressure Filter

Construction : Other, Cartridge type, Steel bowl with head assembly

Feature : High pressure filtering, robust design, efficient particle removal

Mesh : Microglass fiber / Stainless steel wire mesh

Flow Rate : Up to 600 LPM (Liters Per Minute)

PALL Low Pressure Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Filter Type : Low Pressure, Return Line

Construction : Other, Cartridge type, spinon, or bowl type

Feature : High dirtholding capacity, easy element replacement, low pressure drop, and reliable performance.

Mesh : Microglass fiber, cellulose, or wire mesh

Flow Rate : Up to 600 L/min; model specific

EPE Hydraulic Oil Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Filter Type : Hydraulic Oil Filter, Return Line Filter, Pressure Line Filter

Construction : Other, Cartridge type, pleated filter element with end caps

Feature : High dirt holding capacity, low initial pressure drop, corrosionresistant design, easy installation and replacement

Mesh : Glass fiber mesh, micro glass fiber layers

Flow Rate : Available from 20 LPM to 500 LPM

Send Inquiry

Send Inquiry