Air Filter For Chemical Industry

Air Filter For Chemical Industry Specification

- Filter Type

- Panel / Cartridge Type

- Temperature Range

- -10C to 65C

- Connecting Type

- Flange / Threaded

- Capacity

- Customizable

- Filtration Grade

- HEPA / Chemical grade

- Flow Rate

- 6001200 CFM

- Media Type

- Micro-glass fiber / Polyester

- Efficiency (%)

- Up to 99%

- Cleaning Method

- Manual / Compressed air

- Pressure

- Max. 2.5 bar

- Condition

- New

- Material

- Stainless Steel and Synthetic Fiber

- Mesh

- Fine mesh design

- Diameter

- as per requirement

- Construction

- Rugged, corrosion-resistant frame

- Medium Filter

- Activated Carbon / Pleated Media

- Weight

- Approx. 3.5 kg

- Shape

- Cylindrical

- Feature

- High dust holding capacity, chemical resistance, easy installation

Air Filter For Chemical Industry Trade Information

- Payment Terms

- Cheque

- Main Domestic Market

- All India

About Air Filter For Chemical Industry

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Optimal Filtration for Chemical Environments

This air filter combines micro-glass fiber or polyester media with activated carbon or pleated options to effectively trap particulates and chemical contaminants. Its fine mesh, cylindrical design, and corrosion-resistant construction ensure longevity and efficiencymeeting the demanding standards of chemical laboratories and process filtration.

Flexible Installation and Customization

Install the filter seamlessly in vertical or horizontal configurations using flange or threaded connections. Customizable capacities, diameters, and flow directions (inside-out or outside-in) allow for specific needs in chemical plants or labs. Rugged construction and easy cleaning methods enhance user convenience and operational uptime.

FAQs of Air Filter For Chemical Industry:

Q: How should the air filter for chemical industry be installed?

A: The filter can be installed in either vertical or horizontal orientation, depending on your systems design. It supports both flange and threaded connections, ensuring compatibility with various setups in chemical plants and laboratories.Q: What maintenance process is recommended for this filter?

A: Regular cleaning is suggested, using manual brushing or compressed air depending on the buildup. Replacement is advised every 612 months to maintain optimal performance and filtration efficiency.Q: Where is this filter typically used in the chemical industry?

A: It is commonly applied in chemical plants, laboratories, and process filtration areas where high-efficiency removal of chemical contaminants and dust is required.Q: What are the benefits of using this air filter in chemical applications?

A: Benefits include high dust holding capacity, chemical resistance, robust corrosion-resistant frame, and efficiency up to 99%. The filter also features easy installation and customizable options for different process needs.Q: When should the air filter be replaced?

A: For best performance, replace the air filter every 6 to 12 months, depending on operational conditions and dust load, as indicated by a decrease in flow rate or filtration efficiency.Q: What filtration media and grade options are available?

A: The filter comes in HEPA or chemical-grade variants with media options including micro-glass fiber, polyester, activated carbon, or pleated synthetic fibers to address specific contaminant profiles.Q: How can the filters efficiency and capacity be tailored to my requirements?

A: Capacity, diameter, filter type (panel or cartridge), and flow rate (6001200 CFM) are customizable to meet unique process specifications. Please contact the manufacturer or supplier with your technical needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Filters Manufacturers - Industrial Air Filters Category

CYLINDRICAL FILTER CARTRIDGE

Condition : New

Flow Rate : 500 LPH to 5000 LPH

Shape : Cylindrical

Filtration Grade : Other, Micro filtration

Mesh : Woven mesh available in various micron ratings

Feature : High dirt holding capacity, robust construction, easy installation

Lube Oil Filters

Condition : New

Flow Rate : 30 to 200 LPM (varies by model)

Shape : Cylindrical

Filtration Grade : Other, Industrial

Mesh : Pleated fine mesh (various micron ratings available)

Feature : High dirt holding capacity, corrosion resistance, and long service life

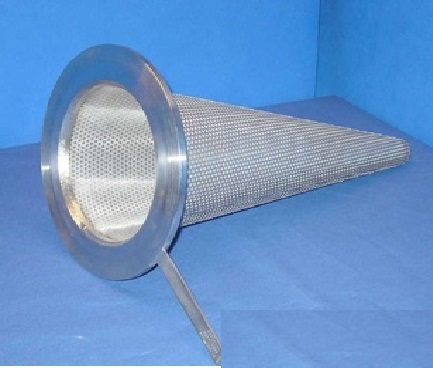

Sintered Mesh Cone Filter

Condition : New

Flow Rate : 0.530 m/h depending on dimensions

Shape : Cone

Filtration Grade : Other, High Precision

Mesh : Multilayer Sintered Woven Mesh

Feature : HighDurability, Corrosion Resistant, Precise Filtration

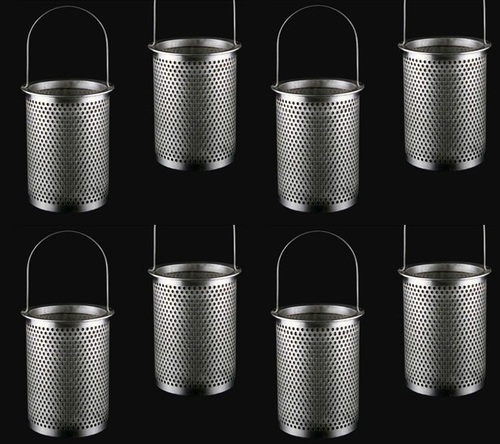

Stainless Steel Mesh Filter Basket

Condition : New

Flow Rate : 10150 L/min (varies with mesh and size)

Shape : Cylindrical Basket

Filtration Grade : Other, Fine / Coarse mesh options

Mesh : Fine Mesh (typically 30100 micron, customizable)

Feature : Corrosion Resistance, High Durability, Reusable, Fine Filtration

Send Inquiry

Send Inquiry