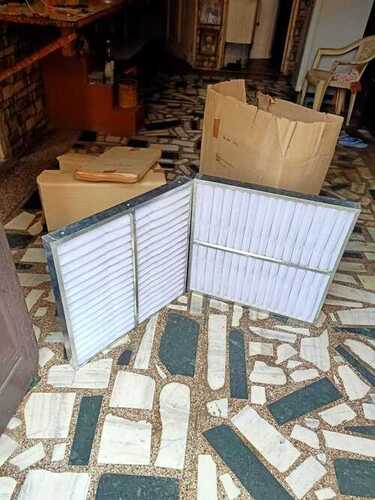

Fine Filter

Fine Filter Specification

- Media Type

- Fine mesh stainless steel / synthetic

- Flow Rate

- Up to 5000 m/hr

- Filter Type

- Panel / Cartridge

- Cleaning Method

- Manual / Backwash

- Filtration Grade

- Fine Grade

- Efficiency (%)

- Up to 99%

- Pressure

- Max. 6 Bar

- Connecting Type

- Threaded / Flanged

- Capacity

- Up to 2000 Liters

- Temperature Range

- up to 120C

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Fine mesh

- Diameter

- Customizable (Standard: 2 to 10)

- Construction

- Welded, heavy-duty frame

- Medium Filter

- Synthetic fiber / wire mesh

- Weight

- 2-6 kg (varies by diameter)

- Shape

- Round / Cylindrical

- Feature

- High efficiency particulate filtration

- Packing Type

- Carton / Wooden box

- Maximum Particle Retention Size

- Down to 5 microns

- Surface Finish

- Electropolished / Brushed

- Installation Orientation

- Vertical or Horizontal

- Corrosion Resistance

- Excellent

- Operating Environment

- Wet and dry filtration systems

- Color

- Metallic silver

- End Connection

- BSP/NPT threaded or custom flange

- Application

- Industrial liquid and air filtration

- Seal Type

- Silicone / EPDM

- Maintenance Interval

- 6-12 months (depending on use)

About Fine Filter

Fine FilterTrusted Across Commercial and Industrial Sectors

Our Fine Filter is widely used by manufacturers, commercial facilities, and process plants requiring efficient air and liquid filtration. It demonstrates exceptional performance in power plants, food and beverage production, chemical processing units, and HVAC applications. The filters high efficiency and robust construction make it a reliable choice for both heavy-duty and sensitive plant operations, ensuring cleaner processes and improved equipment longevity in a range of commercial and industrial environments.

Sample Options, Handover, and Packaging for Domestic Delivery

We offer Fine Filter samples for your evaluation at a reasonable asking price. Each unit is securely packed in either carton or wooden boxes to ensure safe handover and delivery via trusted transport services. Our main domestic market is India, where prompt and reliable logistics support your procurement process. Upon request, samples and bulk orders are shipped quickly to facilitate immediate integration into your operations, demonstrating our dedication to accessible and hassle-free supply.

FAQs of Fine Filter:

Q: How is the Fine Filter installed in industrial systems?

A: The Fine Filter can be seamlessly installed either vertically or horizontally, using its BSP/NPT threaded connections or custom flanges. This flexible design makes it compatible with various industrial piping configurations and easy to retrofit into existing systems.Q: What are the main benefits of using this filter in commercial applications?

A: The Fine Filter offers up to 99% filtration efficiency, excellent corrosion resistance, and robust durability. Its fine mesh construction ensures effective particle retention, reducing equipment maintenance needs and supporting cleaner operations across commercial facilities.Q: Where can the Fine Filter be used most effectively?

A: It is ideally suited for industrial liquid and air filtration, particularly in power plants, chemical processing units, HVAC systems, and food and beverage production plants where demanding filtration efficiency is a priority.Q: When should the filter be maintained or replaced?

A: The recommended maintenance interval is every 6-12 months, depending on the intensity and nature of usage. Regular cleaningmanual or through backwashpreserves optimal filter efficiency and extends service life.Q: What types of media and seal materials are offered with this product?

A: The Fine Filter uses either fine mesh stainless steel or synthetic fiber as filtration media, with sealing options in silicone or EPDM for reliable leak-proof operation in diverse environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filter Manufacture From India Category

AHU Pre Filter In Krishnanagar West Bengal

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Shape : Square

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

Product Type : Flange or Box

Size : Customized

AHU Pre Filter In Budaun Uttar Pradesh

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Shape : Square

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

Product Type : Flange or Box

Size : Customized

AHU Pre Filter In Bharuch Gujarat

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Shape : Square

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

Product Type : Flange or Box

Size : Customized

AHU Pre Filter In Bhadrak Odisha

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Shape : Square

Usage : POWER PLANT,CEMENT PLANT,STEEL PLANT,FERTILIZER,TEXTILE

Product Type : Flange or Box

Size : Customized

Send Inquiry

Send Inquiry