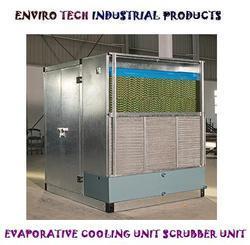

Evaporative Cooling Unit Scrubber

Evaporative Cooling Unit Scrubber Specification

- Refrigerating Capacity

- N/A (Evaporative process)

- Air Flow

- 18000 m/h

- Application

- Industrial Air Cooling, Dust Collection, Air Scrubbing

- Motor

- 1.5 HP

- Material

- Mild Steel / FRP

- Condition

- New

- Type

- Evaporative Cooling Unit with Scrubber

- Dimension (L*W*H)

- 1100 x 1100 x 1000 mm

- Power Supply

- Electric

- Voltage

- 220-380 V

- Cooling Type

- Evaporative

- Nozzle Material

- Brass

- Cooling Coil Material

- N/A (No cooling coil in evaporative unit)

- Water Flowing Rate

- 25 L/min

- Water Pump Motor

- 0.5 HP

- Noise Control

- Below 70 dB

- Compressor

- Not Required (Evaporative cooling uses water evaporation, not compression)

- Fan Type

- Axial Flow Fan

- Usage

- Factories, Foundries, Workshops, Chemical Plants

- Installation

- Easy to Install & Operate

- Mounting

- Floor Mounted

- Color

- Blue & Gray

- Automation Grade

- Semi-Automatic

- Air Outlet Type

- Top/Side Discharge

- Dust Removal Efficiency

- Up to 95%

- Water Tank Capacity

- 60 Liters

About Evaporative Cooling Unit Scrubber

With the assistance of our robust team of technical professionals, we are engaged in manufacturing, exporting and supplying an excellent array of Evaporative Cooling Unit Scrubber. The offered scrubber is manufactured at our production unit by using best grade raw materials and modern machines. This scrubber is used to install in air conditioners for cooling purpose. In addition to this, our clients can purchase this Evaporative Cooling Unit Scrubber at affordable prices from us.

Features:

- High operational fluency

- Require minimum maintenance

- Excellent performance

- Rugged design

Advantages:

- Low installation cost, Low running/operation cost

- Effective in high heat generation areas

- Easy & inexpensive maintenance

- Healthier System - Since it works on 100% fresh air

Application:

- Industrial, Poultry farm, Green House, Mushroom farms Central Air - Cooling System

Technical Features:

Frame/Panel | Single Skin - high grade galvanized steel frame/panel duly treated for outdoor duty. Extruded aluminium profile as option for framework. |

Fan/Motor Deck | DIDW Forward/Backward curve dynamically and statically balanced fans and motor assembled on extruded aluminium profile and mounted on Vibration isolators |

Fill Deck | The wet deck contains specially treated flute media evaporation cooling pad capable of absorbing and retaining water to provide the maximum cooling efficiency. The cellulose media being treated with stiffening and wetting agents provides the cooling without any water carry over. The cross-corrugated media maximize the mixing of air and water. The saturation efficiency ranging from 50% to 90% can be achieved depending upon air velocity and depth of the cooling pad |

Spray Deck (Scrubber) | The wet deck contains double bank spray arrangement with brass nozzles and 4 bend eliminator to remove carbon and oil from exhaust air |

Water Storage | Water storage tank of Galvanized sheet - FRP lined (optional)/SS-304/Aluminium providers connections for water make-up, overflow, drain & recirculation with brass strainer |

Air Filter | Air filter section designed and properly framed, containing washable air filters of expanded aluminium media |

Finish | Powder coated /Prepainted finish unit provided for outdoor installation |

Optional | Double Bank Filter Section |

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

How Does Evaporative Cooling and Scrubbing Work?

This unit draws warm, dust-laden air through wetted surfaces, where dust particles are trapped in water droplets. The cooled and cleaned air is then discharged from the top or side outlets. No compressors or cooling coils are required; water evaporation powers the efficient cooling mechanism.

Effortless Installation and Operation

Engineered for straightforward setup, this floor-mounted system can be easily installed in most industrial spaces. The semi-automatic operation simplifies the daily use, while maintenance is minimized due to sturdy construction with mild steel or FRP.

Designed for Demanding Industrial Applications

With its large capacity and high air flow, the unit serves environments such as workshops, chemical plants, and foundries, ensuring effective air scrubbing and temperature reduction. The blue and gray design adds a professional appearance to any industrial setting.

FAQs of Evaporative Cooling Unit Scrubber:

Q: How does the evaporative cooling unit scrubber remove dust from the air?

A: The scrubber uses an axial flow fan to pull air through water-saturated pads, trapping dust and particles as the air passes. This process can remove up to 95% of airborne dust, delivering cleaner, cooler air to your workspace.Q: What is the installation process for this cooling unit?

A: Installation is straightforward due to its floor-mounted design. Simply connect the unit to a compatible power source (220-380V), fill the 60-liter water tank, and position the air outlet as desired (top or side discharge). No special foundation or compressor setup is required.Q: Where is this evaporative cooling unit commonly used?

A: This system is ideal for factories, foundries, workshops, and chemical plantsany environment where industrial air cooling and dust removal are required.Q: What are the benefits of choosing an evaporative cooling unit with a scrubber?

A: Key advantages include significant dust removal (up to 95%), high cooling capacity without a compressor, easy installation, reduced energy consumption, and lower noise (below 70 dB). It is an eco-friendly choice for improving air quality and comfort in large spaces.Q: What type of maintenance does this unit require?

A: Routine maintenance involves periodically cleaning or replacing the wetted pads, checking and topping up the water tank, and inspecting the fan and motor for any operational issues. The design minimizes maintenance downtime.Q: How much water does the unit consume during operation?

A: The system uses water at a flowing rate of approximately 25 liters per minute during active cooling and scrubbing, supplied from its 60-liter onboard tank or an external source if required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Cooling System Category

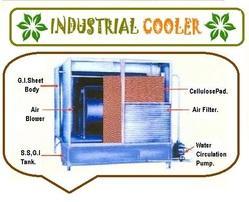

Industrial Cooler

Dimension (L*W*H) : 1400 x 1100 x 1700 mm

Material : Other , Powder Coated Steel Body

Power Supply : AC 220240V, 50/60Hz

Motor : Heavy Duty Copper Motor, 1.5 HP

Type : Industrial Air Cooler

Air Flow : 18000 m3/h

Ductable Unit Floor Mounted

Dimension (L*W*H) : 2200 mm x 800 mm x 1300 mm

Material : Other , Galvanized Steel Sheet

Power Supply : 3 Phase, 415V, 50Hz

Motor : High Efficiency TEFC Motor

Type : Floor Mounted Ductable Unit

Air Flow : 5000 CFM

Air Washer System

Dimension (L*W*H) : Customized as per requirement, e.g. 1200 x 1000 x 1200 mm

Material : Other , Mild Steel (MS) / Galvanized Sheets with Powder Coating

Power Supply : 3Phase, 50 Hz

Motor : 1 HP to 3 HP (as per capacity)

Type : Evaporative Air Cooling System / Air Washer System

Air Flow : 6000 25000 m/hr (varies by model)

Single Skin Air Washer

Dimension (L*W*H) : Customized as per project requirement

Material : Other , GI Powder Coated / Stainless Steel / Aluminum

Power Supply : AC Electric, 50/60Hz

Motor : High Efficiency TEFC Motor (Single/Three Phase)

Type : Single Skin Air Washer

Air Flow : 3000 to 20000 CFM (Customized as per requirement)

Send Inquiry

Send Inquiry