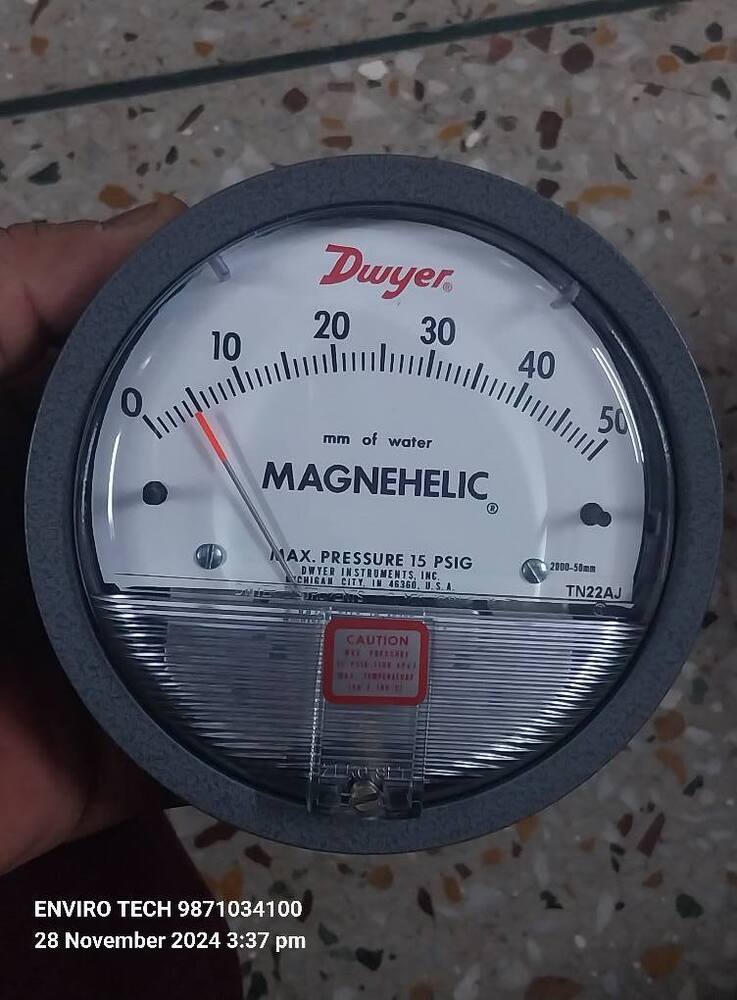

Dwyer Series 2300 Magnehelic Differential Pressure Gauge

Dwyer Series 2300 Magnehelic Differential Pressure Gauge Specification

- Outer Size

- 115 mm (4.5 inches) diameter

- Seal Material

- Neoprene

- Sensor Type

- Differential Pressure Sensing

- Display

- Analog

- Grade

- Industrial

- Thread

- 1/8 NPT High and Low Pressure Connections

- Material

- Die-cast aluminum case, acrylic lens

- Dial Material

- Acrylic

- Pointer Material

- Aluminum

- Processing Type

- Die casting

- Diameter

- 4.5 inches

- Glass Size

- 115 mm round dial

- Mount Type

- Surface or flush mounting

- Scale Range

- 0-0.5 to 0-60 in. wc and metric ranges

- Accuracy

- 2% of full scale

- Finishing

- Die-cast aluminum case

- Measure Pressure Of

- Air and non-combustible gases

- Accessories

- Mounting ring and hardware included

- Ingress Protection

- Weatherproof consult manufacturer

- Weight

- 470 grams approx.

- Installation Orientation

- Any position

- Zero Adjustment

- External adjustment screw

- Resolution

- Fine increments as per scale

- Pressure Units

- inches of water column (in. wc), pascal, mm wc and kPa

- Process Connection

- Dual 1/8" NPT (high and low pressure)

- Instrument Type

- Differential Pressure Gauge

- Maximum Pressure

- Over-pressure protection up to 15 psig

- Case Material

- Die-cast aluminum with corrosion-resistant coating

- Hysteresis

- Low friction mechanism ensures minimal hysteresis

- Operating Temperature Range

- -20 to 60C (-4 to 140F)

- Lens Material

- Clear acrylic

Dwyer Series 2300 Magnehelic Differential Pressure Gauge Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Asia, Central America

- Main Domestic Market

- All India

About Dwyer Series 2300 Magnehelic Differential Pressure Gauge

Dwyer Series 2300 Magnehelic Differential Pressure Gauge

Indicate Positive, Negative or Differential, Accurate within 1%

Select the SERIES 2000 Magnehelic Gage for a versatile low differential pressure gage with a wide choice of 81 models and 27 options to choose from. Using Dwyers simple, frictionless Magnehelic gage movement, it quickly indicates air or noncorrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration, over-pressures and is weatherproof to IP67. Select the -HA High Accuracy Magnehelic Gageoption for an accuracy within 1% of full scale, located below in the Product Configurator. Also included with the HA option at no extra cost are a mirrored scale overlay and a 6 point calibration certificate.

Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

Product Applications

- Filter Monitoring

- Air Velocity with Dwyer Pitot Tube

- Blower Vacuum Monitoring

- Fan Pressure Indication

- Duct, Room or Building Pressures

- Clean Room Positive Pressure Indication

| Model | Description Range - Inches of Water - Zero Center |

| 2300-0 | Differential pressure gage, range 0.25-0-0.25" w.c., minor divisions .01, calibrated for vertical scale position. |

| 2301 | Differential pressure gage, range 0.5-0-0.5" w.c., minor divisions .02. |

| 2302 | Differential pressure gage, range 1-0-1" w.c., minor divisions .05. |

| 2304 | Differential pressure gage, range 2-0-2" w.c., minor divisions .10. |

| 2310 | Differential pressure gage, range 5-0-5" w.c., minor divisions .20. |

| 2320 | Differential pressure gage, range 10-0-10" w.c., minor divisions .50. |

| 2330 | Differential pressure gage, range 15-0-15" w.c., minor divisions 1.0. |

Accurate and Reliable Measurement

The Dwyer Series 2300 Magnehelic Gauge provides dependable measurement of differential pressures with low hysteresis, ensuring minimal reading errors. Designed for accuracy within 2% of full scale, it is perfect for monitoring filter status, air velocity, or pressurized enclosures in demanding industrial settings.

Versatile Installation Options

This gauge can be mounted in any orientation, compatible with both surface and flush mounting requirements. Its compact 4.5-inch diameter ensures it fits a wide range of panels and enclosures, while the included accessories streamline installation, whether in a factory or field setup.

Rugged Industrial Construction

Engineered with a die-cast aluminum case coated for corrosion resistance and a robust acrylic lens, the Dwyer Magnehelic Gauge withstands harsh industrial conditions. Its neoprene seals and weatherproofing support reliable operation in varied environmentsconsult the manufacturer for optimal ingress protection.

FAQs of Dwyer Series 2300 Magnehelic Differential Pressure Gauge:

Q: How do I install the Dwyer Series 2300 Magnehelic Differential Pressure Gauge?

A: The gauge can be mounted in any orientation using surface or flush methods. All necessary mounting rings and hardware are included. Ensure the dual 1/8" NPT process connections are securely attached to your high and low pressure lines before use.Q: What types of media can this gauge measure pressure for?

A: This instrument is designed to measure the differential pressure of air and non-combustible gases only. Avoid using it with liquids or corrosive gases, as this may damage the internal mechanisms and compromise accuracy.Q: When should I use the zero adjustment feature?

A: Use the external zero adjustment screw before each series of measurements or if you notice the pointer off zero when there is no pressure difference. This helps maintain consistent accuracy as environmental conditions or installation position change.Q: Where can this gauge be used?

A: The gauge is suitable for industrial environments, including HVAC systems, cleanrooms, filter monitoring, and laboratories. Its weatherproof case allows for use in less controlled environmentsplease consult the manufacturer for detailed ingress protection recommendations.Q: What is the benefit of the low hysteresis mechanism in the Magnehelic gauge?

A: The low-friction mechanism minimizes hysteresis, ensuring you obtain highly consistent readings during both increasing and decreasing pressure cycles. This enhances overall accuracy and reliability, especially in applications demanding precise monitoring.Q: How do I read the measurements on the dial?

A: The display features a clear round acrylic dial with fine increments, available in multiple pressure units including inches of water column, pascals, mm wc, and kPa. Select a scale range that matches your application for optimal resolution and clarity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer 2000 Magnehelic Differential Pressure Gage Category

DWYER Magnehelic Gauge From Karnataka Industrial Area

Dial Material : Plastic

Diameter : 4 inch / 100 mm

Pointer Material : Alloy

Material : Metal Alloy

Display : Analog

Processing Type : Standard

Dwyer USA Magnehelic Gauges 0 To 100 Inch WC

Dial Material : Other, Polystyrene

Diameter : 4 inch (101.6 mm)

Pointer Material : Aluminum

Material : Other, Diecast aluminum case

Display : Analog

Processing Type : Other, Precision engineered

Dwyer USA Magnehelic Gauges 0 To 50 Inch WC

Dial Material : Other, White, easyread dial face

Diameter : 43/4 inch (120 mm)

Pointer Material : Other, Precision balanced aluminum pointer

Material : Other, Diecast Aluminum Case

Display : Analog

Processing Type : Other, Diecast

Dwyer USA Magnehelic Gauges 0 To 5.0 Inch WC

Dial Material : Other, ABS Plastic

Diameter : 4 inch (100 mm) face

Pointer Material : Aluminum

Material : Other, Die Cast Aluminum Case

Display : Analog

Processing Type : Other, Precision Machined

Send Inquiry

Send Inquiry