Dwyer MS 711 Magnesense Differential Pressure Transmitter

Dwyer MS 711 Magnesense Differential Pressure Transmitter Specification

- Display

- LED and LCD (optional, depending on model)

- Seal Material

- Silicone

- Thread

- 1/8 NPT

- Grade

- Industrial

- Sensor Type

- Differential Pressure Sensor

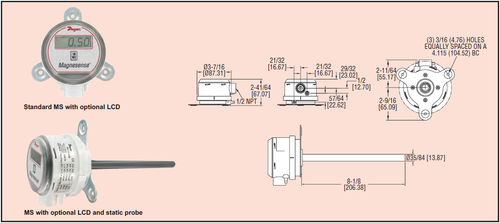

- Outer Size

- Approx. 62.6 mm (2.47) diameter housing

- Material

- Polycarbonate housing with silicon sensor

- Processing Type

- Electronic

- Diameter

- 62.6 mm (2.47)

- Mount Type

- Surface/Wall Mount

- Scale Range

- 0 to 250 Pa (or other ranges available depending on model)

- Accuracy

- 1% of Full Scale

- Finishing

- Polycarbonate housing, grey finish

- Measure Pressure Of

- Air or non-combustible, compatible gases

- Accessories

- Mounting screws, installation manual

- Output Signal

- 4-20 mA or 0-10 VDC (selectable)

- Pressure Port Material

- Brass

- Power Supply

- 10-35 VDC, 10-32 VAC

- Enclosure Rating

- IP66

- Electrical Connection

- Terminal block

- Response Time

- 250 ms

- Operating Temperature Range

- -10°C to +50°C (14°F to 122°F)

- Weight

- 0.20 kg (approx.)

- Approval / Certification

- CE, RoHS

- Zero & Span Adjustment

- Push-button

Dwyer MS 711 Magnesense Differential Pressure Transmitter Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Paypal, Cash Against Delivery (CAD), Cheque

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Dwyer MS 711 Magnesense Differential Pressure Transmitter

Dwyer Instruments MS-711

Magnesense Differential Press. Trans., 5 VDC, 1, 2, 5 in H2O

The Series MS Magnesense Differential Pressure Transmitter is an extremely versatile transmitter for monitoring pressure and air velocity. This compact package is loaded with features such as: field selectable English or metric ranges, field upgradeable LCD display, adjustable dampening of output signal (with optional display) and the ability to select a square root output for use with Pitot tubes and other similar flow sensors. Along with these features, the magnetic sensing technology provides exceptional long term performance and enables the Magnesense transmitter to be the solution for a myriad of pressure and flow applications. Field Upgradeable LCD. No need to order two separate transmitters. Simply stock a transmitter and display and you can satisfy any customer's requests. Simply remove cover and snap the LCD onto the board. Field Selectable Ranges in metric or English. Lowers stock and inventory requirements. You'll always have the right transmitter for every job. Digital Push Button Zero and Span. Reduces calibration time significantly over other transmitters that utilize potentiometers. Lowers maintenance time and costs. Adjustable Digital Dampening smooths out unstable pressure fluctuations common in air flow applications. Field Selectable Air Velocity Mode for fan and blower applications. Unit provides square root output that accurately tracks fpm or m/s flow rate. No need for a smart programmable indicator or PLC to convert pressure to air flow. Reduces components and installation time lowering overall costs

Product Highlights

5 VDC output

selectable range 1, 2, 5 in H2O (250, 500, 1250 Pa)

panel mount

Versatile Output Signals

Choose between 4-20 mA or 0-10 VDC output signals, making the Dwyer MS 711 transmitter ideal for integration with most building management systems and industrial automation platforms. The flexibility to select the output optimizes compatibility and simplifies installation processes.

Durable Industrial Construction

Encased in a robust, grey polycarbonate housing with an IP66 rating, this transmitter withstands demanding environments. The enclosures compact size and wall-mount design offer streamlined installation without sacrificing protection against dust and moisture.

Simple Calibration and Setup

The push-button zero and span adjustment ensures straightforward calibration, while an optional LED or LCD display provides instant on-site feedback. Mounting screws and a detailed installation manual are included for hassle-free commissioning and maintenance.

FAQs of Dwyer MS 711 Magnesense Differential Pressure Transmitter:

Q: How do I select between the 4-20 mA and 0-10 VDC output signals on the Dwyer MS 711 transmitter?

A: You can select your preferred output signal (4-20 mA or 0-10 VDC) using the devices configuration options during installation. Refer to the installation manual for step-by-step instructions and wiring guidance.Q: What types of media can be measured by the MS 711 differential pressure transmitter?

A: The transmitter is designed to measure the differential pressure of air or non-combustible, compatible gases. It is not suitable for use with flammable gases or liquids.Q: When is it necessary to perform zero and span adjustment on this device?

A: Zero and span adjustments are recommended upon initial installation, after major maintenance, or if you observe any drift in readings. The device offers a push-button feature to make calibration quick and convenient.Q: Where should the Dwyer MS 711 be installed for optimal performance?

A: Install the transmitter on a stable, vibration-free wall or surface close to the pressure source, using the provided mounting screws. Ensure the location is within the specified operating temperature range (-10C to +50C) and protected from extreme environmental conditions.Q: What is the process for connecting the electrical wiring to the unit?

A: Electrical connections are made via a terminal block inside the enclosure. After routing your wiring, simply loosen the housing, connect each wire as indicated in the manual, and tighten the terminal screws securely before resealing the enclosure.Q: How does the device ensure measurement accuracy and signal stability?

A: The MS 711 offers 1% full-scale accuracy, a fast 250 ms response time, and utilizes a silicon sensor to deliver reliable, stable output even in rapidly changing conditions. Factory calibration and push-button adjustments further support sustained accuracy.Q: What are the main benefits of choosing the Dwyer MS 711 for industrial applications?

A: Key benefits include robust environmental protection (IP66), flexible output selection, easy calibration, optional digital display, and adherence to CE and RoHS standards. Its compact size and user-friendly features make it ideal for diverse industrial and building management scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Magnesense Differential Pressure Transmitter Category

Dwyer MS 121 Magnesense Differential Pressure Transmitter

Minimum Order Quantity : 12 Pieces

Processing Type : Other, Electronic sensor, solidstate

Accuracy : 1% of Full Scale

Display : LCD Digital

Grade : Industrial

Thread : 1/8 NPT Female Pressure Connections

Dwyer MS 341 Magnesense Differential Pressure Transmitter

Minimum Order Quantity : 12 Pieces

Processing Type : Other, Electronic

Accuracy : 1% of Full Span

Display : LCD Display

Grade : Industrial

Thread : Barbed for 1/8 to 3/16 ID tubing

Dwyer MS 351 Magnesense Differential Pressure Transmitter

Minimum Order Quantity : 12 Pieces

Processing Type : Other, Electronic

Accuracy : 1% of FS

Display : LCD Digital Display

Grade : Industrial

Thread : 1/8 NPT Female

Dwyer MS 321 Magnesense Differential Pressure Transmitter

Minimum Order Quantity : 1 Piece

Processing Type : Other, Factory Calibrated

Accuracy : 1% FS

Display : No Display (Analog output signal)

Grade : Industrial

Thread : 1/8 NPT Female

Send Inquiry

Send Inquiry