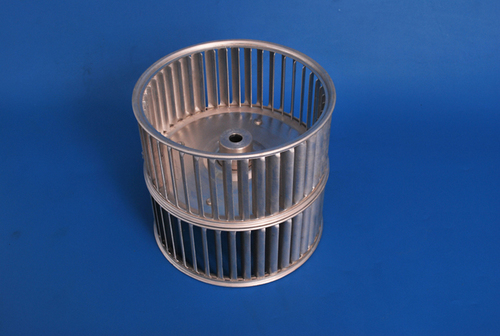

DIDW Centrifugal Fan 530 MM X 530 MM

DIDW Centrifugal Fan 530 MM X 530 MM Specification

- Efficiency

- >75%

- Air Flow

- 50007000 m/h

- Temperature

- Ambient: Up to 60C

- Instruments Type

- Fan/Blower

- Automation Grade

- Semi Automatic

- Measurement

- Air Volume

- Orientation

- Horizontal

- Power Source

- Electric

- Usage & Applications

- Industrial ventilation, HVAC, Air handling units, Exhaust systems

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooling

- Noise Level

- <85 dB

- Capacity

- 50007000 m/h

- Voltage

- 415 V

- Weight

- Approx. 95 kg

- Dimension (L*W*H)

- 530 mm x 530 mm x 680 mm

- Surface

- Powder Coated

- Drive Type

- Belt Driven

- Impeller Type

- Backward Curved

- Inlet/Outlet Shape

- Rectangular

- Number of Blades

- 12

- Mounting Type

- Floor Mounted

- Fan Speed

- 1440 RPM

- Application Area

- Factories, Commercial Buildings, Warehouses, Clean Rooms

- Rotation

- Clockwise / Counterclockwise

- Motor Power

- 35 HP

- Static Pressure

- 80200 mm WG

- Protection Class

- IP55

- Bearing Type

- Ball Bearing

DIDW Centrifugal Fan 530 MM X 530 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 530 MM X 530 MM

DIDW Centrifugal Fan 530 MM X 530 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 63 | ETIP 21 21 | 530 X 530 X 430 | 21 X 21 | 35 MM,40 MM,& 1.5'' | AL. / GI. |

Efficient Airflow for Industrial Environments

The DIDW Centrifugal Fan provides consistent air delivery and effective ventilation for diverse industrial settings. With its high-efficiency backward curved impeller and semi-automatic controls, it ensures optimal air movement, supporting applications such as HVAC, exhaust systems, and air handling units. Its robust motor and ball bearing design offer long-term durability and minimal maintenance.

Versatile Installation and Application

Designed for convenient floor mounting, this fan integrates seamlessly into commercial, manufacturing, and warehouse settings. Its belt-driven configuration allows for easy maintenance and accommodates variable motor power from 3 to 5 HP. The powder-coated, mild steel construction guarantees toughness against harsh environments and continuous operation.

FAQs of DIDW Centrifugal Fan 530 MM X 530 MM:

Q: How should the DIDW Centrifugal Fan be installed in an industrial facility?

A: The fan is designed for floor mounting, ensuring stability and easy integration with existing HVAC or ventilation setups. Ensure sufficient clearance for airflow and maintenance access, and secure alignment with the rectangular inlet/outlet ducts.Q: What are the primary applications for this centrifugal fan model?

A: This model is ideal for industrial ventilation, HVAC systems, air handling units, exhaust systems, and maintaining air quality in factories, warehouses, commercial buildings, and clean rooms.Q: When is it beneficial to use a backward curved impeller in ventilation systems?

A: Backward curved impellers are optimally used when higher efficiency and lower noise are required. They prevent dust accumulation and provide reliable performance with less maintenance, especially in environments with demanding airflow needs.Q: Where is the best location to place the centrifugal fan for effective operation?

A: Position the fan where unobstructed air intake and discharge can be ensuredtypically at ground level near ventilation duct connections, away from structural obstacles or heat sources, and where regular maintenance can be performed safely.Q: What is the process for maintaining this centrifugal fan?

A: Routine maintenance involves inspecting and lubricating the ball bearings, verifying belt tension, checking for unusual vibrations or noise, and cleaning the powder-coated surface and impeller to ensure uninterrupted airflow.Q: How does the IP55 protection class benefit the operation of this fan?

A: IP55 indicates resistance to dust and water jets, enhancing the fans durability in industrial settings with challenging particulate or moisture exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 380 MM X 380 MM

Price 9000 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Air Cooled

Product Type : DIDW Centrifugal Fan

Voltage : 220380 V

Usage & Applications : Ventilation, Air Handling Units, HVAC, Industrial Air Circulation

DIDW Centrifugal Fan 280 MM X 200 MM

Price 3000 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Air Cooled

Product Type : DIDW Centrifugal Fan

Voltage : 415 V

Usage & Applications : Air ventilation, HVAC, fume extraction, clean rooms

DIDW Centrifugal Fan 115 MM X 127 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Air Cooled

Product Type : DIDW (Double Inlet Double Width) Centrifugal Fan

Voltage : 230V / 415V AC

Usage & Applications : HVAC systems, Exhaust, Ventilation, Air Handling Units

DIDW Centrifugal Fan 300 MM X 305 MM

Price 6000 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Air Cooling

Product Type : Centrifugal Fan

Voltage : 215/415 Volt(v)

Usage & Applications : Industrial

Send Inquiry

Send Inquiry