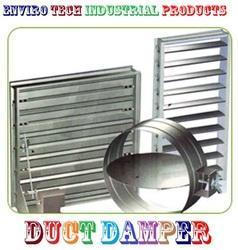

Volume Control Damper

Volume Control Damper Specification

- Maintenance Type

- Periodic cleaning and inspection

- Flow Rate

- Variable as per application

- Hole Size

- Customized as required

- Efficiency (%)

- Over 95%

- Energy Consumption

- Zero (manual operation)

- Ventilation

- Suitable for HVAC ventilation ducts

- Filtration Property

- No filtration (damper only)

- Pressure Range

- Up to 1500 Pa

- Installation Type

- Flanged

- Control System

- Manual handle

- Material

- Galvanized Iron Sheet

- Equipment Type

- Volume Control Damper

- Color

- Silver grey

- Features

- Corrosion resistant coating, robust construction

- Noise Level

- Low operation

- Output

- Optimized air distribution

- Filters

- Filter compatibility available

- Application

- Used in HVAC ducting systems

- Humidity %

- Up to 90%

- Automatic Grade

- Manual

- Capacity

- Designed for efficient airflow regulation

- Dimension (L*W*H)

- Customized as per duct size

- Weight

- Depends on dimension

About Volume Control Damper

As a client centric firm, we are offering our clients an excellent quality Volume Control Damper that is designed to used in ventilation system for volume control. In order to manufacture this damper in tune with international quality standards, our adroit professionals use quality-approved components with the aid of contemporary techniques. It is also tested on defined quality parameters to assure its hassle-free operations. In addition to this, our clients can avail this Volume Control Damper in different technical specifications at marginal prices from us.

Features:

- High tensile strength

- Long service life

- Rugged design

- Rust proof

Versatile Blade Design and Customizable Sizing

Select between opposed or parallel blades for precise airflow regulation tailored to your HVAC requirements. Frame thickness and overall dimensions are customizable to fit your duct layout perfectly, ensuring a seamless installation in both new and retrofit projects.

Durability and Maintenance

Constructed from galvanized iron, this damper boasts a corrosion-resistant finish and robust design for a long operational lifespan of more than 50,000 cycles. Maintenance is minimal, typically requiring periodic cleaning and inspection for peak performance and longevity.

Optimized Airflow with Minimal Leakage

Engineered meticulously, the damper achieves low air leakage as per SMACNA standards. The rubber gasket seals each blade, enhancing energy efficiency and overall indoor air quality by preventing unwanted air bypass within HVAC ductwork.

FAQs of Volume Control Damper:

Q: How do I select between opposed and parallel blade types for my application?

A: Opposed blade dampers are ideal for uniform airflow control across larger ducts, commonly used in general HVAC ventilation. Parallel blade dampers offer quick on/off operation, suiting situations that require swift or full duct opening. The appropriate blade type depends on your systems airflow objectives and distribution requirements.Q: What are the benefits of the dampers powder-coated or hot dip galvanized finish?

A: Both finishes provide superior corrosion protection. Powder coating offers a smooth, aesthetically pleasing surface, while hot dip galvanizing delivers robust resistance against harsh environmental conditions, extending damper service life even in humid or corrosive environments.Q: Where can these volume control dampers be installed?

A: These dampers are suitable for both vertical and horizontal installations within HVAC ventilation ducts. With customized sizing available, they can be mounted in new systems or integrated into existing ducting infrastructure in commercial, residential, or industrial settings.Q: What is the process for maintaining the volume control damper?

A: Maintenance involves periodic inspection for dust accumulation or mechanical wear. Cleaning the blades and inspecting the rubber gaskets ensure low leakage and optimal function over time. No special tools or complex procedures are required for regular upkeep.Q: When should I consider adding a motorized actuator to the damper?

A: A motorized actuator is recommended if you require automated or remote damper control, such as in advanced HVAC systems with centralized management. Our dampers feature provision for easy actuator integration, allowing future upgrades without extensive modifications.Q: What advantages does the dampers low leakage design offer?

A: Low air leakage, verified by SMACNA standards, ensures that conditioned air remains within the duct, boosting system efficiency, reducing energy costs, and maintaining targeted ventilation rates. This also leads to improved occupant comfort and consistent performance.Q: How does the damper handle different environmental conditions?

A: Designed to perform between -10C to 70C and up to 90% humidity, the damper is suitable for a wide range of Indian climates. Its corrosion-resistant finish further ensures durability and reliability under diverse operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Volume Control Damper Manufacturers In Delhi Category

Duct- damper

Efficiency (%) : High

Installation Type : Other, Inline Duct Installation

Automatic Grade : Automatic

Noise Level : Low

Features : Durable Adjustable High Performance

Material : Galvanized Steel

Back Draft Dampers

Efficiency (%) : High efficiency in airflow prevention

Installation Type : Inline duct installation, Other

Automatic Grade : Automatic

Noise Level : Silent operation

Features : Prevents reverse airflow Durable construction

Material : Metal typically galvanized steel or aluminum

Low Leakage Duct Damper

Efficiency (%) : 99.5

Installation Type : Portable

Automatic Grade : Automatic

Noise Level : Medium db

Features : Durable

Material : Mild Steel

Collar- damper

Efficiency (%) : 99.5

Installation Type : Portable

Automatic Grade : Automatic

Noise Level : Medium db

Features : Durable

Material : Mild Steel

Send Inquiry

Send Inquiry