Sensocon USA SERIES 211-D250A-1 Differential Pressure Transmitter

Sensocon USA SERIES 211-D250A-1 Differential Pressure Transmitter Specification

- Outer Size

- Approx. 110 mm x 90 mm x 53 mm

- Seal Material

- EPDM

- Sensor Type

- Differential Pressure Sensor

- Thread

- 1/8 NPT Female

- Display

- LCD Digital Display

- Grade

- Industrial

- Material

- ABS Plastic Housing

- Processing Type

- Electronic

- Mount Type

- Wall Mount

- Scale Range

- 0-250 Pa

- Accuracy

- 1% FS

- Finishing

- Powder Coated

- Measure Pressure Of

- Air and Compatible Gases

- Accessories

- Mounting Screws, Instruction Manual

Sensocon USA SERIES 211-D250A-1 Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India

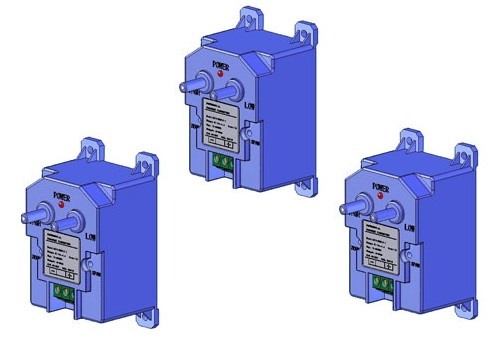

About Sensocon USA SERIES 211-D250A-1 Differential Pressure Transmitter

- Model 211-250A-1

- Pressure Range 0-250 PA

- Accuracy 1%

- Compact Design

- 0.25% Accuracy

- LED Power Indication

- 4 20 mA or 0 10 V output

SPECIFICATIONS

- Maximum Pressure:

- Ranges 5 PSI (35 kPa) = 15 PSI (100 kPa) Max Ranges > 5 PSI (35 kPa) = 30 PSI (200 kPa) Max

- Media Compatibility:

- Air and compatible noncombustible, non-corrosive gasses

- Accuracy:

- Ranges 4 w.c. (1 kPa) 1.0% Ranges 5 w.c. (1.25 kPa) 0.25%

- Temperature Ranges:

- Compensated: 15 to 120F (-10 to 50C) Operating: -10 to 155F (-25 to 70C)

- Thermal Effect:+/- 0.028% FS/F (+/- 0.050%/C)

- Stability: +/- 0.25% FS/year

- Output Signal: 4-20 mA, 2 wire or 0-10V

- Loop Resistance: 250 @ 24 VDC

- Power Supply: 12-30 VDC

- Housing Material: ABS Plastic

- Electrical Connections: screw terminals

- Process Connection: Push on connection for 3/16 I.D. tubing

- Agency Approvals: CE

Precision Differential Pressure Measurement

The SERIES 211-D250A-1 delivers accurate and reliable differential pressure readings for air and compatible gases. With a measurement range of 0250 Pa and a high level of accuracy, it supports various industrial monitoring applications, from HVAC to cleanroom control. The integrated LCD display ensures clear, real-time results.

Rugged and Versatile Design

Built with a powder-coated ABS housing and rated IP54, this transmitter withstands challenging industrial environments. It features straightforward wall mounting and a compact 110 x 90 x 53 mm form factor, making installation hassle-free. Its 1/8 NPT female threads support standard industrial connections.

User-Friendly Operation and Adjustability

Zero and span adjustments are accomplished easily with dedicated push buttons, allowing quick calibration. The transmitters digital display guides setup and diagnostics. Supplied accessories like mounting screws and an instruction manual streamline initial setup and ongoing operation.

FAQs of Sensocon USA SERIES 211-D250A-1 Differential Pressure Transmitter:

Q: How is the Sensocon SERIES 211-D250A-1 differential pressure transmitter installed?

A: Installation is simple thanks to the included wall-mount brackets and screws. Position the transmitter on a flat surface, connect the air or gas input using the 1/8 NPT female threads, and wire the electrical terminal block to your 12-36 VDC power supply and 4-20 mA output signal path as described in the instruction manual.Q: What media can the SERIES 211-D250A-1 measure pressure for?

A: This transmitter is specifically designed to measure the differential pressure of air and other non-corrosive gases that are compatible with its ABS plastic housing and EPDM seals. Avoid exposing it to corrosive or flammable gases to maintain sensor accuracy and longevity.Q: Where can this differential pressure transmitter be used?

A: Ideal for industrial applications, it is commonly used in HVAC systems, clean rooms, filter monitoring, and other processes requiring low-range air pressure measurement. Its IP54 enclosure makes it suitable for environments with moderate dust or moisture exposure.Q: What is the process for zero and span adjustment?

A: Zero and span adjustments are performed directly on the device using the built-in push buttons. Follow the on-screen prompts on the LCD display to calibrate the transmitter to your systems requirements, ensuring precise and tailored pressure readings.Q: When is it beneficial to use a differential pressure transmitter with a digital display?

A: A digital display provides immediate and clear visual feedback, which is particularly beneficial for on-site monitoring, system troubleshooting, or routine maintenance where quick identification of pressure levels is critical.Q: What are the advantages of the 4-20 mA output signal?

A: The 4-20 mA current output is highly noise-resistant, allowing reliable transmission of data over long cable runs. It is widely compatible with industrial control systems and ensures accurate representation of measured pressure within the specified range.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon 211 Differential Pressure Transmitter Category

Sensocon USA SERIES 211-D002K-3 Differential Pressure Transmitter

Seal Material : Silicone

Sensor Type : Differential Pressure Transmitter

Material : Other, ABS Plastic Body

Outer Size : Approx. 120 mm x 80 mm x 50 mm

Mount Type : Other, Panel or Surface Mount

Accessories : Mounting Hardware, Manual

Sensocon USA SERIES 211-D100K-3 Differential Pressure Transmitter

Seal Material : Silicone

Sensor Type : Differential Pressure Transmitter

Material : Other, ABS Plastic Housing

Outer Size : 112 x 70 x 36 mm (approx)

Mount Type : Other, Wall / Surface Mount

Accessories : Mounting Screws, Instruction Manual

Sensocon USA SERIES 211-D500A-1 Differential Pressure Transmitter

Seal Material : BunaN Rubber

Sensor Type : Differential Pressure Sensor

Material : Other, Anodized Aluminum Housing

Outer Size : D500A1 Model Specific

Mount Type : Other, Panel / Surface Mount

Accessories : Mounting Bracket, Installation Manual

Sensocon USA SERIES 211-D004I-1 Differential Pressure Transmitter

Seal Material : Silicone

Sensor Type : Differential Pressure Transmitter

Material : Other, Polycarbonate Housing

Outer Size : 118 mm x 132 mm x 59 mm (Approx)

Mount Type : Other, Surface or Wall Mount

Accessories : Mounting Screws, Instruction Manual

Send Inquiry

Send Inquiry