Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5003

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5003 Specification

- Display

- Analog

- Outer Size

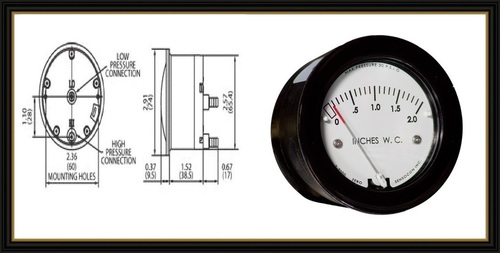

- 2 (50.8 mm) Diameter Case

- Grade

- Industrial

- Sensor Type

- Differential Pressure Gauge

- Thread

- 1/8 NPT Female

- Seal Material

- Silicone Rubber

- Bourdon Tube

- Not Applicable (Diaphragm based)

- Material

- ABS Plastic Case, Acrylic Lens, Brass Fittings

- Dial Material

- Plastic

- Pointer Material

- Plastic

- Processing Type

- Injection Molded

- Diameter

- 2 Inch (50.8 mm)

- Glass Size

- 1.7 Inch (43 mm)

- Mount Type

- Surface or Panel Mount

- Scale Range

- 0-3 WC (Water Column) / 0-75 mm WC (standard), other ranges available

- Accuracy

- 4% of Full Scale

- Finishing

- Black Plastic Case

- Measure Pressure Of

- Air and Compatible Gases

- Accessories

- 2 Mounting Brackets, 2 Static Pressure Tips, 1.5 m Flexible Tubing

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5003 Trade Information

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5003

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5003

Description

Mounts in Industry Standard Holes

Accuracy 5%

Low-Cost Miniature Size

The Series S-5000 is a low cost, diaphragm operated, differential pressure gauge in a miniature housing. The S-5000 can be used in applications for measuring positive, negative, or differential pressure with an accuracy of 5%. Standard applications include monitoring filter status, duct static pressure, room pressure, fan or blower pressure, paint booths, dust collectors, and cabinet purging along with many others.

Customizing Options Available

MODEL NUMBERS

| MODEL NUMBERS | Pressure Range |

| S-5003 | 0 3" |

SPECIFICATIONS

Pressure Limits: 30 PSI (2.067 bar)

Media Compatibility: Air and compatible non-corrosive gasses

Accuracy: +/- 5% full scale throughout range at 70F (21C)

Temperature Ranges: 20 to 120F (-7 to 49C)

Housing Material: Glass-filled nylon, polycarbonate cover

Process Connection: Barbed connections for 3/16" I.D. tubing

Weight: 6 oz (170 g)

Accessories: Two mounting studs and hex nuts, allen wrench, and panel mounting bracket

Agency Approvals: RoHS, CE

Versatile Applications in Industrial Environments

The S-5003 pressure gauge is engineered for a variety of HVAC and industrial monitoring needs. Whether youre tracking filter performance, measuring duct static pressure, or ensuring clean room integrity, this gauge delivers consistent analog readings. Its compatibility with air and inert gases enhances utility across numerous settings.

Compact, Durable, and Easy to Install

Housed in a tough ABS plastic case with an acrylic lens and brass fittings, the S-5003 stands up to demanding environments. Weighing just 80 grams and measuring only 2 inches in diameter, it fits seamlessly into panel or surface mounts. With included mounting brackets and accessories, installation is straightforward and efficient.

Reliable Performance and Accurate Measurement

With an external screw adjustment for zeroing and a pressure range up to 5 psi, the S-5003 ensures readings remain accurate over time. The 4% full-scale accuracy and diaphragm-based sensor technology provide trustworthy results, critical for maintaining safe and optimized operations in industrial systems.

FAQs of Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5003:

Q: How do I install the Sensocon S-5003 Differential Pressure Gauge?

A: Installation is straightforward with the included mounting brackets and 1.5-meter flexible tubing. Simply connect the gauges two 1/8" NPT female ports to your pressure source using the static pressure tips, mount on a surface or panel, and youre ready to begin measurements.Q: What kind of maintenance does the S-5003 require?

A: Routine maintenance mainly involves ensuring the pressure ports and tubing remain clear of debris. Periodic external zero adjustment can be done using the dedicated screw feature to maintain accuracy over time.Q: When should I use this pressure gauge in my HVAC system?

A: This gauge is ideal for continuous monitoring of filter condition, duct static pressure, and blower efficiency. Use it when you need timely, reliable analog readings to manage airflow or diagnose issues within your HVAC system.Q: Where can the S-5003 gauge be utilized besides HVAC setups?

A: Beyond HVAC, the S-5003 is perfect for clean room monitoring, general air velocity measurements, and any application requiring low-cost, accurate differential pressure readings of air or compatible gases.Q: What benefits does the diaphragm-based sensor provide over other designs?

A: Diaphragm-based sensors, as used in the S-5003, offer stable and repeatable pressure readings, especially at low differential pressures. This design also reduces the likelihood of mechanical failure compared to conventional bourdon tube designs.Q: How accurate are the readings from the S-5003 gauge?

A: The gauge provides accuracy within 4% of full scale, ensuring that your pressure readings are both reliable and consistent for industrial monitoring or process control needs.Q: What materials are used in the construction of the S-5003, and how do they enhance durability?

A: The S-5003 uses an ABS plastic case, acrylic lens, brass fittings, and silicone rubber seals. These quality materials provide resistance to environmental factors and enhance the devices longevity in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon USA S-5000 Differential Pressure Gauge Category

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5005

Seal Material : BunaN

Thread : 1/8 NPT

Accessories : Mounting Bracket (Standard), Connection Fittings

Glass Size : 2 inches (approx.)

Measure Pressure Of : Other, Air and compatible noncorrosive gases

Accuracy : 2% of full scale

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-25MM

Seal Material : Silicone

Thread : 1/8 NPT

Accessories : Mounting Bracket Optional

Glass Size : 25 mm (Window Diameter)

Measure Pressure Of : Other, Air and Noncorrosive Gases

Accuracy : 2% Full Scale

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-500PA

Seal Material : Rubber

Thread : 1/8 NPT

Accessories : Mounting hardware

Glass Size : 60 mm

Measure Pressure Of : Other, Air and compatible gases

Accuracy : 3% of full scale

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5001

Seal Material : Silicone

Thread : 1/8 NPT Female

Accessories : Surface Mounting Bracket Included

Glass Size : Not Applicable (Clear Polycarbonate Cover)

Measure Pressure Of : Other, Air and Compatible Gases

Accuracy : 2% of Full Scale

Send Inquiry

Send Inquiry