Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-50MM

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-50MM Specification

- Display

- Analog

- Bourdon Tube

- Not Applicable (Diaphragm Sensing Element)

- Grade

- Industrial

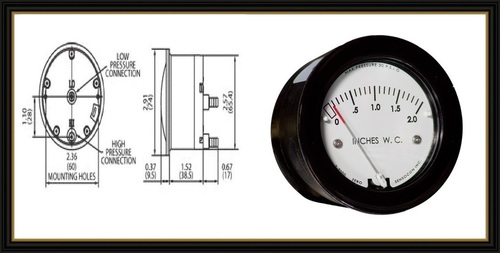

- Outer Size

- 55mm x 55mm (approx.)

- Thread

- 1/8 NPT (Both High and Low Pressure Ports)

- Sensor Type

- Differential Pressure

- Seal Material

- Silicone Rubber

- Material

- ABS Plastic Body, Polycarbonate Front Cover

- Dial Material

- Aluminum with Polycarbonate Overlay

- Pointer Material

- ABS / Polypropylene

- Processing Type

- Injection Molded Housing

- Diameter

- 50mm

- Glass Size

- 50mm

- Mount Type

- Panel or Surface Mount

- Scale Range

- 0-50 mm WC

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated / Painted

- Measure Pressure Of

- Low Pressure Gases/Air

- Accessories

- Panel Mounting Bracket

About Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-50MM

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-50MM

Description

Mounts in Industry Standard Holes

Accuracy 5%

Low-Cost Miniature Size

The Series S-5000 is a low cost, diaphragm operated, differential pressure gauge in a miniature housing. The S-5000 can be used in applications for measuring positive, negative, or differential pressure with an accuracy of 5%. Standard applications include monitoring filter status, duct static pressure, room pressure, fan or blower pressure, paint booths, dust collectors, and cabinet purging along with many others.

Customizing Options Available

MODEL NUMBERS

| MODEL NUMBERS | Pressure Range |

| S-5000-50MM | 0 50 mm |

SPECIFICATIONS

Pressure Limits: 30 PSI (2.067 bar)

Media Compatibility: Air and compatible non-corrosive gasses

Accuracy: +/- 5% full scale throughout range at 70F (21C)

Temperature Ranges: 20 to 120F (-7 to 49C)

Housing Material: Glass-filled nylon, polycarbonate cover

Process Connection: Barbed connections for 3/16" I.D. tubing

Weight: 6 oz (170 g)

Accessories: Two mounting studs and hex nuts, allen wrench, and panel mounting bracket

Agency Approvals: RoHS, CE

Versatile Industrial Pressure Monitoring

Designed to address the needs of HVAC systems, laboratory clean rooms, and industrial sites, the S-5000-50MM differential pressure gauge offers versatile installationthanks to its side-mounted 1/8 NPT connection and optional panel mounting bracket. Its light 95-gram construction and compact outer size make it effortless to integrate into confined spaces, while an immediate response time ensures real-time monitoring.

Robust Build for Precise Applications

With strict attention to durability and longevity, this gauge features an ABS plastic housing and a polycarbonate front cover, ensuring resilience against harsh environments. Its injection-molded construction and silicone rubber seals help maintain accuracy and reliability under demanding conditions. Ideal for continuous monitoring in filtration and air flow systems, it operates seamlessly between -10C and +60C.

FAQs of Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-50MM:

Q: How do I install the S-5000-50MM Differential Pressure Gauge?

A: The gauge offers flexibility in installationit can be panel or surface mounted using the included mounting bracket. Simply connect both high and low-pressure ports using 1/8 NPT fittings located on the side, ensuring secure and leak-free attachment for accurate functioning.Q: What types of applications are best suited for this pressure gauge?

A: This gauge is optimized for HVAC systems, filter and fan monitoring, clean room environments, and general air or gas flow measurement where low differential pressure needs to be tracked reliably. Its rugged construction also supports usage in other industrial air and gas measurement scenarios.Q: When can I expect to see changes reflected on the gauge?

A: The S-5000-50MM offers immediate, instantaneous response due to its spring diaphragm mechanism, providing real-time analog indications as pressure varies.Q: Where should the gauge be mounted for ideal performance?

A: It can be mounted on control panels or any accessible surface near your monitoring point. For the best results, avoid locations exposed to excessive vibration, corrosive atmospheres, or direct moisture ingress.Q: What process does the gauge use to sense pressure?

A: The gauge utilizes a reliable spring diaphragm sensing element, which measures the difference between two low-pressure gas or air sources applied to each port. The analog pointer reflects this differential on the clear dial.Q: How does this gauge benefit my monitoring system?

A: With its 2% full-scale accuracy and real-time display, the gauge enables early detection of filter clogs, system inefficiencies, or abnormal airflowsupporting preventive maintenance and optimizing system performance.Q: What are the key materials and finishes used in this gauge?

A: Main materials include an ABS plastic body for strength, a polycarbonate front cover for clarity and durability, and silicone rubber seals for leak protection. The unit also features a powder-coated or painted finish for added corrosion resistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon USA S-5000 Differential Pressure Gauge Category

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-25MM

Material : Other, Polycarbonate, ABS

Seal Material : Silicone

Diameter : 25 mm

Sensor Type : Diaphragm

Finishing : Other, Polycarbonate Case, Precision Finish

Pointer Material : Other, ABS Plastic

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5000-100MM

Material : Other, Polycarbonate Housing, Brass Connections

Seal Material : Silicone Rubber

Diameter : 100 mm

Sensor Type : Miniature Differential Pressure Mechanism

Finishing : Other, Black Polycarbonate Case

Pointer Material : Other, Black ABS Plastic

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5002

Material : Other, ABS plastic housing

Seal Material : Synthetic Nitrile Rubber

Diameter : 60 mm

Sensor Type : Diaphragm

Finishing : Other, ABS body, smooth finish

Pointer Material : Aluminum

Sensocon USA Miniature Low Cost Differential Pressure Gauge Series S-5005

Material : Other, ABS Plastic Housing, Brass Connections

Seal Material : BunaN

Diameter : 2.4 inches (61 mm)

Sensor Type : Differential Pressure Gauge

Finishing : Other, Black plastic housing

Pointer Material : Plastic

Send Inquiry

Send Inquiry