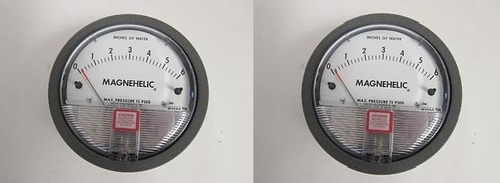

Sensocon USA Magnehelic Gauges 0 To 10 MM WC

Sensocon USA Magnehelic Gauges 0 To 10 MM WC Specification

- Display

- Analog

- Sensor Type

- Diaphragm, Differential Pressure

- Thread

- 1/8 NPT

- Outer Size

- Approx. 115 mm dia.

- Seal Material

- Silicone / Neoprene

- Grade

- Industrial Grade

- Material

- Die-cast Aluminum Case, Polycarbonate Front

- Dial Material

- ABS Plastic

- Pointer Material

- Aluminum

- Processing Type

- Precision Machined

- Diameter

- 115 mm (Case Diameter)

- Glass Size

- Full view window approx. 100 mm

- Mount Type

- Surface / Flush Mount

- Scale Range

- 0 to 10 mm WC

- Accuracy

- 2% of full scale

- Finishing

- Powder Coated / Anodized

- Measure Pressure Of

- Low Differential Air and Non-Corrosive Gases

- Accessories

- Mounting bracket, Screws, User Manual

Sensocon USA Magnehelic Gauges 0 To 10 MM WC Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India

About Sensocon USA Magnehelic Gauges 0 To 10 MM WC

Sensocon USA Magnehelic Gauges 0 To 10 MM WC

INCLUDES

Two 1/8" NPT plugs, two 1/8" rubber tubing adapters, and three mounting adapters with screws

MORE ABOUT THIS ITEM

The Magnahelic guage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. The gauge's motion is damped with high-viscosity silicone fluid. The zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness. Rugged design resists shock, vibration, and overpressure.

The helix is precision-made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the maganetic field to move the pointer across the scale. The samarium cobalt magnet is mounted at one end of the range spring and rotates the helix without mechanical linkages.

Specifications & Description

- Accuracy±2% full-scale

- Dial Size (in)4

- Dial Size (mm)102

- Min Pressure (in WC)0

- Max Pressure (in WC)10

- Wetted MaterialsAluminum

- CaseAluminum

- Lens Materialacrylic

- Process Connection1/8" NPT

- Unit Of Measurement" WC

- Displayanalog dial

- Media CompatibilityGases and liquids compatible with wetted materials

- Resolution0.20

- DescriptionMagnehelic Differential Pressure Gauge, Type , 0 to 10 MM WC

Reliable Differential Pressure Measurement

The Sensocon USA Magnehelic Gauge addresses the crucial need for accurate low-pressure readings in air and non-corrosive gas applications. Its industrial-grade construction and clear, full-view analog dial make it the trusted choice for environments requiring reliable and immediate pressure data. Popular for use in HVAC, clean rooms, and duct measurement systems.

Designed for Versatility and Durability

This gauge is engineered to support both vertical and horizontal installations, and its die-cast aluminum housing with powder-coated or anodized finishing guarantees lasting performance. The precision-machined body and high-quality sensor diaphragm ensure stable readings even in variable operating conditions.

Simple Installation and Maintenance

With user-friendly mounting accessories included and an external zero adjustment screw, installation and periodic calibration are straightforward. The external adjustments eliminate the need to disassemble the device, allowing for quick maintenance and uninterrupted operation in critical environments.

FAQs of Sensocon USA Magnehelic Gauges 0 To 10 MM WC:

Q: How do I mount the Sensocon USA Magnehelic Gauge for optimal accuracy?

A: For the most precise measurements, mount the gauge in a vertical position as standard. However, if your application requires horizontal mounting, the Magnehelic Gauge can accommodate this as well. Securely use the provided mounting bracket and screws during installation to ensure stability and accuracy.Q: What is the recommended application for this gauge?

A: This Magnehelic Gauge is designed for measuring low differential air and non-corrosive gas pressures in HVAC systems, filter status monitoring, clean room environments, duct static pressure, as well as fan and blower measurements. Its industrial-grade construction ensures reliable performance across these critical applications.Q: When should I use the external zero adjustment screw?

A: Use the external zero adjustment screw to recalibrate the gauge if you notice any shift in the zero point, typically after installation or during routine maintenance checks. This allows you to maintain measurement accuracy without dismantling the device.Q: Where can this gauge be installed?

A: You can install the gauge on any suitable flat surface using the surface or flush mount options provided. It is designed to be versatile for a range of industrial settings, whether in machinery panels, ductwork, or clean room walls, accommodating both vertical and optional horizontal orientations.Q: What processes does the gauge monitor and how does it benefit users?

A: The gauge monitors air and non-corrosive gas pressure differences, which is essential for ensuring HVAC efficiency, identifying filter clogging, maintaining proper clean room conditions, and optimizing duct flow. This results in enhanced process reliability, reduced downtime, and improved operational safety.Q: What are the usage guidelines for maximum pressure and temperature?

A: Operate the gauge within its specified maximum pressure of 200 kPa (29 psi) and temperature range of -20C to +60C. Operating beyond these limits may affect the accuracy or integrity of the device.Q: How is the pressure displayed on this Magnehelic Gauge?

A: The device features a clear, analog display with a full-view window (about 100 mm in diameter). Readings are given directly in mm WC (millimeters water column), allowing for immediate and intuitive assessment of pressure levels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer Magnehelic Differential Pressure Gauge Model 2000-0.5KPA

Minimum Order Quantity : 12 Pieces

Display : Analog dial

Accessories : Two 1/8 NPT plugs, two mounting screws, instruction sheet

Material : Other, Diecast aluminum case, polycarbonate window

Thread : 1/8 NPT high and low pressure taps

Glass Size : Clear polycarbonate cover, approx. 4 inches

Dwyer 2204 Magnehelic Differential Pressure Gauge 0-4 PSI

Minimum Order Quantity : 12 Pieces

Display : Analog

Accessories : Mounting Bracket (Included), Two 1/8 NPT Plugs, Three Mounting Adapters

Material : Other, DieCast Aluminum Case, Acrylic Cover

Thread : 1/8 NPT

Glass Size : Clear Acrylic (same as dial viewing area)

Dwyer USA Model 2006 Magnehelic Gage Range 0-6.0 Inch WC

Minimum Order Quantity : 12 Pieces

Display : Analog

Accessories : Mounting Kit, Standard Hardware, Two 1/8 NPT Plugs, Rubber Tubing

Material : Other, Die Cast Aluminum Case, Molded Plastic Face, BunaN or Silicone Rubber Diaphragm

Thread : 1/8 NPT Female Connection

Glass Size : Full View Polycarbonate Lens

Dwyer USA 2005 Magnehelic Gage Range 0-5.0 Inch WC

Minimum Order Quantity : 12 Pieces

Display : Analog

Accessories : Mounting Bracket, Two Static Pressure Tips, Two Tubing Pieces, Screws

Material : Other, DieCast Aluminum Case

Thread : 1/8 NPT High And Low Pressure Connections

Glass Size : Full Size Front

Send Inquiry

Send Inquiry