Sensocon USA 212-D003K-3 Differential Pressure Transmitter

Sensocon USA 212-D003K-3 Differential Pressure Transmitter Specification

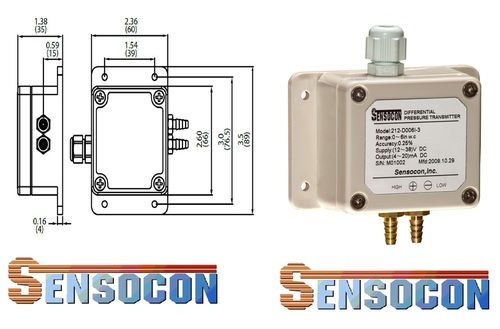

- Outer Size

- 120 mm x 80 mm x 55 mm (Approx)

- Sensor Type

- Differential Pressure Transmitter

- Thread

- 1/8 NPT Female

- Display

- Digital LCD Display

- Grade

- Industrial Grade

- Seal Material

- Silicone Gasket

- Material

- ABS Plastic Body

- Dial Material

- Not Applicable (Digital)

- Pointer Material

- Not Applicable (Digital)

- Processing Type

- Microprocessor-based

- Diameter

- 80 mm (Front panel)

- Mount Type

- Wall Mount

- Scale Range

- 0-3.0 kPa (0-3000 Pa)

- Accuracy

- 1% of full scale

- Finishing

- Polycarbonate Enclosure Finish

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting bracket, instruction manual

Sensocon USA 212-D003K-3 Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Sensocon USA 212-D003K-3 Differential Pressure Transmitter

The Series 212 Weatherproof Differential Pressure Transmitter can accurately measure positive, negative, or differential pressure and send a corresponding 4-20 mA or 0-10 V output signal. The Series 212 Weatherproof Differential Pressure Transmitter is designed with an IP 65 enclosure and can be easily mounted to any flat surface. The Series 212 is not position sensitive and can be mounted in any orientation without compromising accuracy. The compact, lightweight design makes installation simple and easy.

SPECIFICATIONS

- Maximum Pressure: Ranges 5 PSI (35 kPa) = 15 PSI (100kPa) MaxRanges > 5 PSI (35 kPa) = 30 PSI (200kPa) Max

- Media compatibility: Air and compatible non-combustible, non-corrosive gases

- Accuracy: Ranges 4" w.c. (1kPa) 1.0%Ranges 5" w.c. (1.25kPa) 0.25%

- Temperature Ranges: Compensated: 15 to 120F (-10 to 50C)Operating: -10 to 155F (-25 to 70C)

- Thermal Effect: +/- 0.028% FS/F (+/- 0.50% FS/C)

- Stability: +/- 0.25% FS/year

- Output Signal: 4-20 mA, 2-wire or 0 - 10 V

- Loop Resistance: 250 @ 24 VDC

- Power Supply: 12-30 VDC

- Enclosure Rating: IP 65

- Electrical Connections: screw terminals

- Electrical Entry: PG7 Cable Gland

- Process Connection: Barbed fittings for 3/16 flexible tubing

- Agency Approvals: CE

Industrial Grade Precision and Reliability

Engineered for industrial settings, the Sensocon USA 212-D003K-3 delivers high accuracy and stability in monitoring differential pressure of air and non-corrosive gases. Its microprocessor-based processing ensures consistent readouts, while the rugged polycarbonate enclosure and silicone gasket seal protect the sensor from environmental factors. The product is CE marked, meeting international quality and safety standards.

Easy Installation and User-Friendly Adjustment

This transmitter offers straightforward setup with screw terminal electrical connections and a wall mount bracket included. Digital zero and span adjustments via push-button allow for hassle-free calibration, even after installation. The clear digital LCD display simplifies monitoring and diagnostics, ensuring confident system operation.

FAQs of Sensocon USA 212-D003K-3 Differential Pressure Transmitter:

Q: How is the Sensocon USA 212-D003K-3 Differential Pressure Transmitter installed?

A: Installation is simplified with the included wall mount bracket and screw terminal connections. The device should be mounted at your desired location, ensuring stability, and then connected to a 24V DC power source (acceptable range: 12-36V DC) following the instructions provided in the manual.Q: What types of media can this transmitter measure pressure for?

A: The transmitter is designed to measure the differential pressure of air and non-corrosive gases, making it ideal for HVAC applications, clean rooms, and other controlled environments where compatibility and accuracy are paramount.Q: When should zero and span adjustments be performed on the transmitter?

A: Zero and span adjustments using the digital push-button feature should be carried out during initial setup, after significant environmental changes, or whenever calibration checks indicate drift, ensuring optimal accuracy and performance.Q: Where can the Sensocon USA 212-D003K-3 be used?

A: Suitable for use in industrial areas demanding robust instrumentation, such as manufacturing plants, laboratories, and commercial HVAC systems, the transmitter is IP65-rated, allowing installation in locations prone to dust and moisture.Q: What process is used to calibrate this transmitter?

A: Calibration is performed using the integrated digital push-buttons for zero and span settings. The procedure is detailed in the instruction manual, enabling users to make precise adjustments easily without specialized tools.Q: How does the transmitter benefit users in industrial settings?

A: By providing rapid and accurate pressure measurements (response time less than 100 ms) along with a clear LCD display and robust construction, it ensures efficient monitoring and reduces downtime, contributing to safer and more productive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 212 Weather Proof Differential Pressur Transmitter Category

Series 212 Weather-Proof Differential Pressure Transmitter

Accuracy : 1% of Full Scale

Outer Size : WeatherProof Enclosure, IP65

Mount Type : Other, Wall or Panel Mount

Sensor Type : Capacitive Differential Pressure Sensor

Material : Other, Die Cast Aluminum Body

Measure Pressure Of : Other, Air and NonCorrosive Gases

Sensocon USA 212-D002I-1 Differential Pressure Transmitter

Accuracy : 1% of Full Scale

Outer Size : 110 mm x 85 mm x 58 mm

Mount Type : Other, Wall or Surface

Sensor Type : Differential Pressure Transmitter

Material : Other, ABS Plastic Housing

Measure Pressure Of : Other, Air and Noncorrosive Gases

Sensocon USA 212-D001K-1 Differential Pressure Transmitter

Accuracy : 1% of F.S.

Outer Size : Approx. 120 x 90 x 55 mm

Mount Type : Other, Wall/DIN Rail Mount

Sensor Type : Differential Pressure Sensor

Material : Other, Polycarbonate/ABS Housing

Measure Pressure Of : Other, Air and Noncorrosive Gases

Sensocon USA SERIES 212-D250A-1 Differential Pressure Transmitter

Accuracy : 1% of Full Scale

Outer Size : Compact

Mount Type : Other, Surface/Wall Mount

Sensor Type : Differential Pressure Transmitter

Material : Other, Aluminum Housing, ABS Cover

Measure Pressure Of : Other, Air and Noncorrosive Gases

Send Inquiry

Send Inquiry