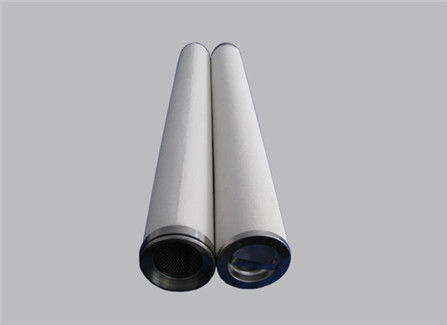

Replacement PALL Oil Coalescing Filter

Replacement PALL Oil Coalescing Filter Specification

- Connecting Type

- OEM compatible, push fit / threaded

- Capacity

- Subject to application and size

- Filtration Grade

- Fine Coalescing

- Temperature Range

- -20C to 120C

- Filter Type

- Replacement Coalescor Cartridge

- Flow Rate

- 10-600 Nm3/h (depending on model)

- Cleaning Method

- Non-washable, replace when indicated

- Pressure

- Max 16 bar

- Efficiency (%)

- Up to 99.99%

- Media Type

- Microglass coalescing media

- Condition

- New

- Material

- Microfiber Glass, Stainless Steel End Caps

- Mesh

- Fine filtration mesh

- Diameter

- Customizable (standard: 65-152 mm)

- Construction

- Deep pleated construction

- Medium Filter

- Oil, Water, Air

- Weight

- Approx. 1.5-5 Kg depending on model

- Shape

- Cylindrical

- Feature

- High oil removal efficiency, enhanced system protection, low pressure drop, long service life

Replacement PALL Oil Coalescing Filter Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Africa, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About Replacement PALL Oil Coalescing Filter

We have been doing Replacement PALL Oil Coalescing Filter so many years to guarantee Replacement PALL Oil Coalescing Filter so just rest assured to choose our Replacement PALL Oil Coalescing Filter.

Category: Coalescer & Separator Tags: Oil Water Separator, Replacement PALL Oil Coalescing Filter

Superior Oil Removal Efficiency

Designed to capture oil aerosols and fine particulates, this replacement coalescing filter offers up to 99.99% efficiency, providing enhanced equipment protection and reduced maintenance downtime. Its advanced microglass media and deep pleated construction enable high flow rates and sustained, low pressure drops vital for compressor and pneumatic system reliability.

Robust Construction for Harsh Conditions

With stainless steel end caps, a perforated steel core, and corrosion-resistant components, the filter withstands up to 16 bar pressure and temperatures from -20C to 120C. These features ensure durability in rigorous industrial applications, making it an optimal choice for long-term operation and reliability in challenging environments.

Customized for Varied Applications

Available in customizable diameters (65-152 mm) and configurations, this cartridge is suited for oil, water, and air filtration in numerous industries. Push fit or threaded OEM-compatible connections simplify integration, while individually sealed, export-worthy packaging ensures safe delivery and storage worldwide.

FAQs of Replacement PALL Oil Coalescing Filter:

Q: How is the Replacement PALL Oil Coalescing Filter installed?

A: The filter is designed for easy integration with existing systems featuring OEM-compatible push fit or threaded connections. Simply replace the old cartridge by aligning and fitting the new filter as per your equipments instructions to ensure a secure and effective seal.Q: What types of fluids or contaminants does this coalescing filter remove?

A: It efficiently removes oil aerosols, water droplets, and fine particulates from compressed air, pneumatic, and hydraulic systems thanks to its advanced microglass coalescing media and fine mesh construction.Q: When should the filter be replaced for optimal performance?

A: It is recommended to replace the filter when the pressure drop reaches 1.5 bar or as indicated by your filtration systems monitoring device. As a non-washable cartridge, continued use beyond this point could reduce efficiency and system protection.Q: Where can this filter be used effectively?

A: The filter is suitable for compressors, pneumatic tools, and hydraulic circuits across industrial, manufacturing, and processing environments, particularly where demanding oil removal and fine particulate filtration are required.Q: What is the benefit of using microfiber glass and stainless steel materials in this filter?

A: Microfiber glass provides superior filtration efficiency for fine contaminants, while stainless steel end caps and support ensure stability, corrosion resistance, and durability for prolonged operational life in harsh settings.Q: What is the process for changing out the filter cartridge?

A: Ensure system pressure is released, then remove the spent filter. Replace it with a new, individually sealed coalescing filter, paying attention to the end cap orientation and sealing material compatibility. Re-pressurize and check for leaks before resuming operation.Q: How does using this filter enhance system performance?

A: Its high oil and particulate removal efficiency, low pressure drop, and deep pleated construction help extend equipment life, reduce maintenance intervals, and ensure reliable, clean operation with minimal energy loss.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

Replace PALL Water Filter Water Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Glass Fiber / Polypropylene / Stainless Steel

Shape : Cylindrical / Customized

Construction : Other, Pleated / Depth / Wrapped

Flow Rate : 20200 LPM (customizable)

Replacement HYDAC Filter Element 0060R Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Glass Fiber, Stainless Steel End Caps

Shape : Cylindrical

Construction : Other, Pleated Element

Flow Rate : Up to 30 L/min

EPE Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Stainless Steel / Glass Fiber / Paper

Shape : Cylindrical

Construction : Other, Pleated/Seamless

Flow Rate : 25800 L/min (Modeldependent)

PALL Filter Cartridge From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Microglass fiber, stainless steel, cellulose

Shape : Cylindrical

Construction : Other, Pleated cartridge

Flow Rate : 120 3500 LPH (Liters per hour) depends on model

Send Inquiry

Send Inquiry