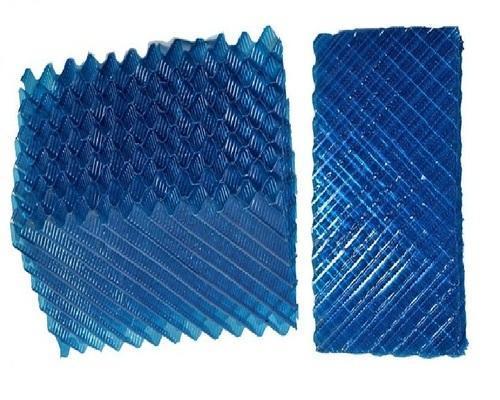

PVC Fills

PVC Fills Specification

- Material

- PVC (Polyvinyl Chloride)

- Application

- Cooling Towers, Water Treatment, HVAC

- Condition

- New

- Type

- Cooling Tower Fill

- Dimension (L*W*H)

- 600 mm x 300 mm x 150 mm (custom sizes available)

- Cooling Type

- Counterflow / Crossflow

- Water Flowing Rate

- Depends on cooling tower specification

- Noise Control

- Indirect, through enhanced cooling efficiency

About PVC Fills

Owing to the immense experience and a competent team of experts, we are able to offer PVC Fills to respectable clients. These PVC Fills offered by us are made utilizing high grade raw material, which is sourced from trustworthy vendors of the market. In addition to this, the offered range of PVC Fills is applicable in humidification, effluent treatment, power, petrochemical, refining, paper chemical, steel and allied industries. This PVC Cooling Tower Fills is known for distributing the liquid and gas across the many interconnected channels within the surface material. For inducing highly turbulent mixing between the water and the air, which increases heat and moisture transfer, cross fluted designs is introduced.

Features:

- Light weight

- Fire safe

- Decay proof

- Mass transfer & heat transfer coefficient

- Low pressure drop

Versatile Cooling Tower Fills for All Applications

Our PVC fills are an ideal solution for both industrial and commercial cooling towers. These fills feature a honeycomb-shaped, corrugated surface to maximize water distribution and airflow. Available in a range of sizes and colors, they accommodate diverse specifications, including custom requirements for specialized projects.

High Durability and Easy Installation

With a thickness range of 0.25 mm to 0.5 mm and robust temperature resistance up to 65C, our PVC fills are designed for longevity. The easy-to-cut material ensures quick installation, saving both time and labor costs. The anti-algae and optional UV-resistant coatings further enhance durability in demanding environments.

Boost Cooling Efficiency and Reduce Maintenance

The advanced design allows for excellent water flow and indirect noise reduction by improving cooling tower efficiency. Smooth surface treatment and anti-algae properties keep maintenance requirements low, supporting reliable long-term performance in water treatment, HVAC, and cooling tower applications.

FAQs of PVC Fills:

Q: How are PVC Fills with a honeycomb, corrugated design installed in cooling towers?

A: These fills are engineered to be easily cut and fitted into both standard and custom frameworks. You can trim the PVC fills to match your towers dimensions and arrange them inside as per the installation instructions. Lightweight material makes the process quick and efficient.Q: What benefits do the anti-algae coating and optional UV resistance bring?

A: The anti-algae coating helps prevent the buildup of organic growth, extending fill lifespan and reducing maintenance. Optional UV resistance protects against sun exposure, preventing material degradation in outdoor settings, particularly important for installations in hot climates.Q: When should you consider custom sizing or block shapes for PVC fills?

A: Custom sizes or shapes are ideal when you have non-standard or uniquely designed cooling towers. Customization ensures maximum efficiency and optimal water distribution, addressing specific engineering requirements that standard blocks may not fulfill.Q: Where can these PVC fills be used beyond cooling towers?

A: Besides cooling towers, these PVC fills are suitable for water treatment plants and HVAC systems. Their flexibility and resilience make them adaptable for various industrial or commercial applications requiring efficient thermal exchange and water management.Q: What is the expected lifespan of these cooling tower fills under normal conditions?

A: When maintained appropriately and used under standard conditions, these PVC fills can last up to 10 years. The durable material, combined with treated surfaces, helps ensure longevity and consistent operational performance.Q: How do these fills impact water flow and cooling efficiency?

A: The corrugated, honeycomb design optimizes water distribution and air contact, increasing the cooling towers efficiency. This enhanced efficiency can also contribute to indirect noise reduction and lowered operational costs for your system.Q: What is the process for requesting custom colors or UV-resistant fills?

A: Simply specify your requirements when placing an order with the manufacturer, supplier, trader, or wholesaler. Options for color and UV-resistance are available on request, ensuring your PVC fills meet all project or environmental specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Tower Fills Honey Comb PVC Fill Manufactur Category

Cooling Tower PVC Fill

Material : PVC

Type : PVC Cooling Tower Fill

Condition : New

Application : Cooling Tower Water Distribution and Heat Exchange Enhancement

Cooling Type : Evaporative Cooling

Dimension (L*W*H) : As per requirement, common sizes include 1200mm x 300mm x 150mm

Cooling Tower FRP Fills

Material : Other , FRP (Fibre Reinforced Plastic)

Type : Fills

Condition : New

Application : Cooling Tower

Cooling Type : Water Cooling

Dimension (L*W*H) : Customizable

White Honeycomb PVC Fills

Material : PVC

Type : Honeycomb

Condition : New

Application : Cooling Tower

Cooling Type : Evaporative Cooling

Send Inquiry

Send Inquiry