Primary Pocket Filters

Price 3500 INR/ Piece

Primary Pocket Filters Specification

- Temperature Range

- -20C to +80C

- Flow Rate

- Customizable, typically 1500-3600 m/h

- Capacity

- High Dust Loading

- Connecting Type

- Flange/Clip-On

- Filtration Grade

- Medium (F5-F9 EN779/ISO16890)

- Pressure

- Initial 60 Pa

- Media Type

- Synthetic Fiber

- Cleaning Method

- Non-Washable, Replaceable

- Efficiency (%)

- Up to 95%

- Filter Type

- Primary Pocket Filter

- Condition

- New

- Material

- Synthetic Fiber with Metal Frame

- Mesh

- Multi-pocket

- Diameter

- Customizable

- Construction

- Pocket/Bag Type with Stitched Pockets

- Medium Filter

- Yes

- Weight

- Lightweight

- Shape

- Rectangular

- Feature

- High Dust Holding Capacity, Low Initial Pressure Drop, Easy Installation, Moisture Resistant

Primary Pocket Filters Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Africa, Asia, Central America

- Main Domestic Market

- All India

About Primary Pocket Filters

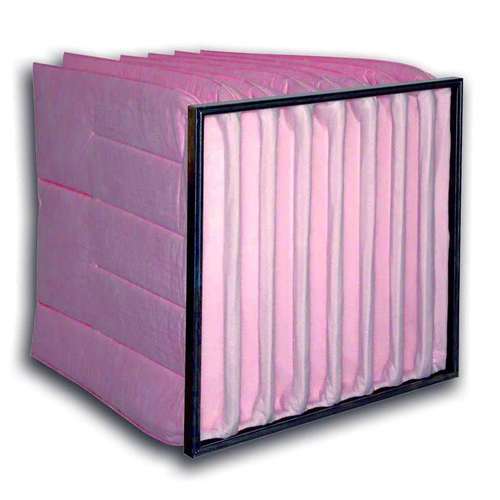

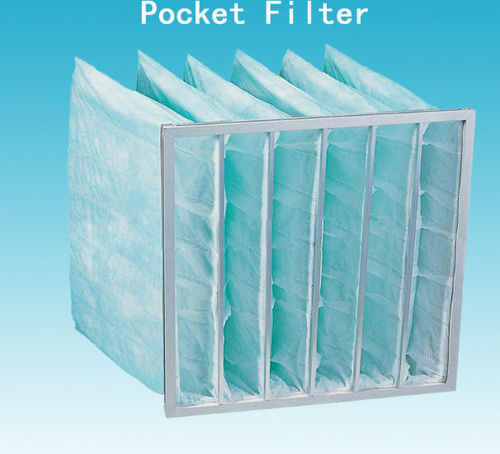

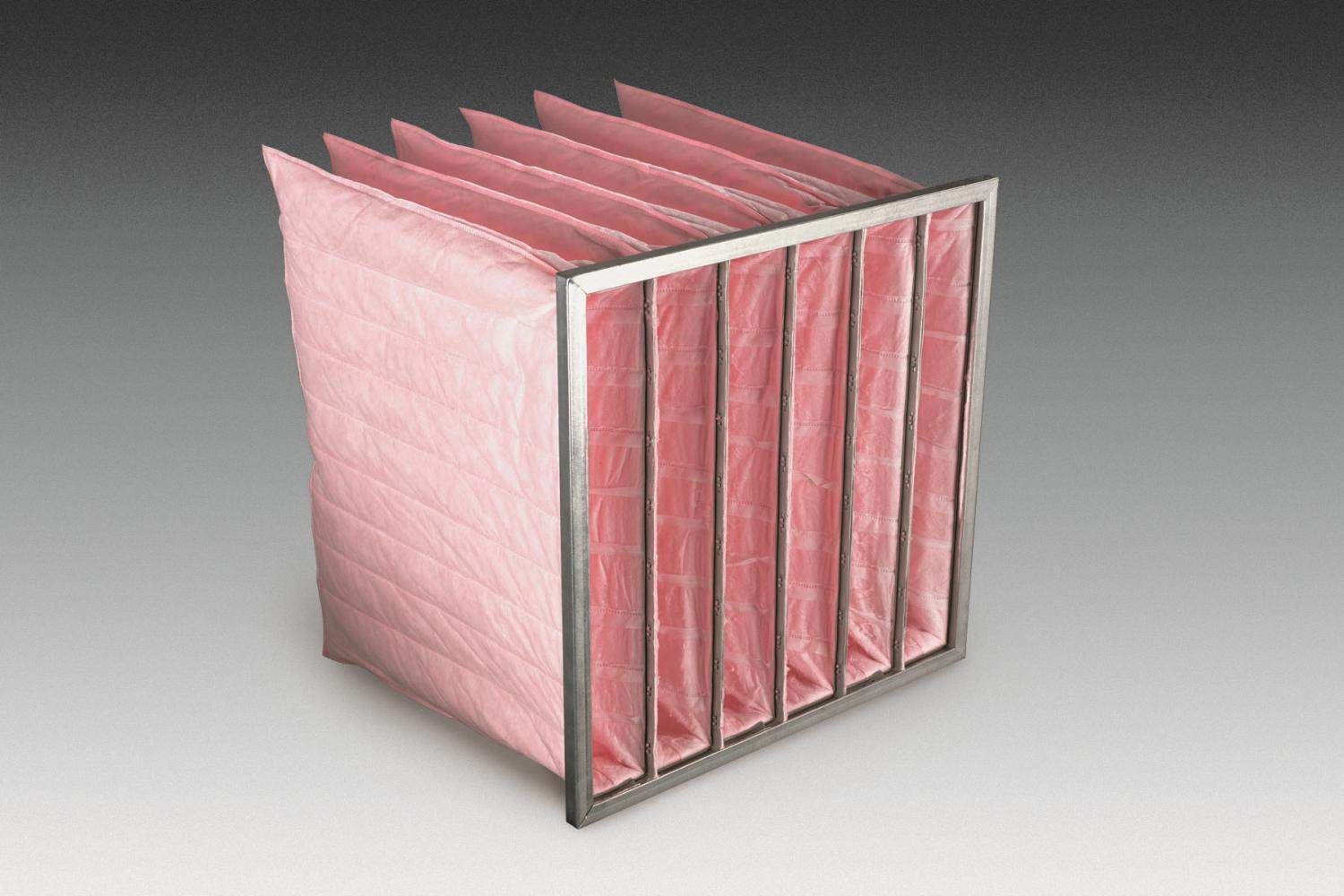

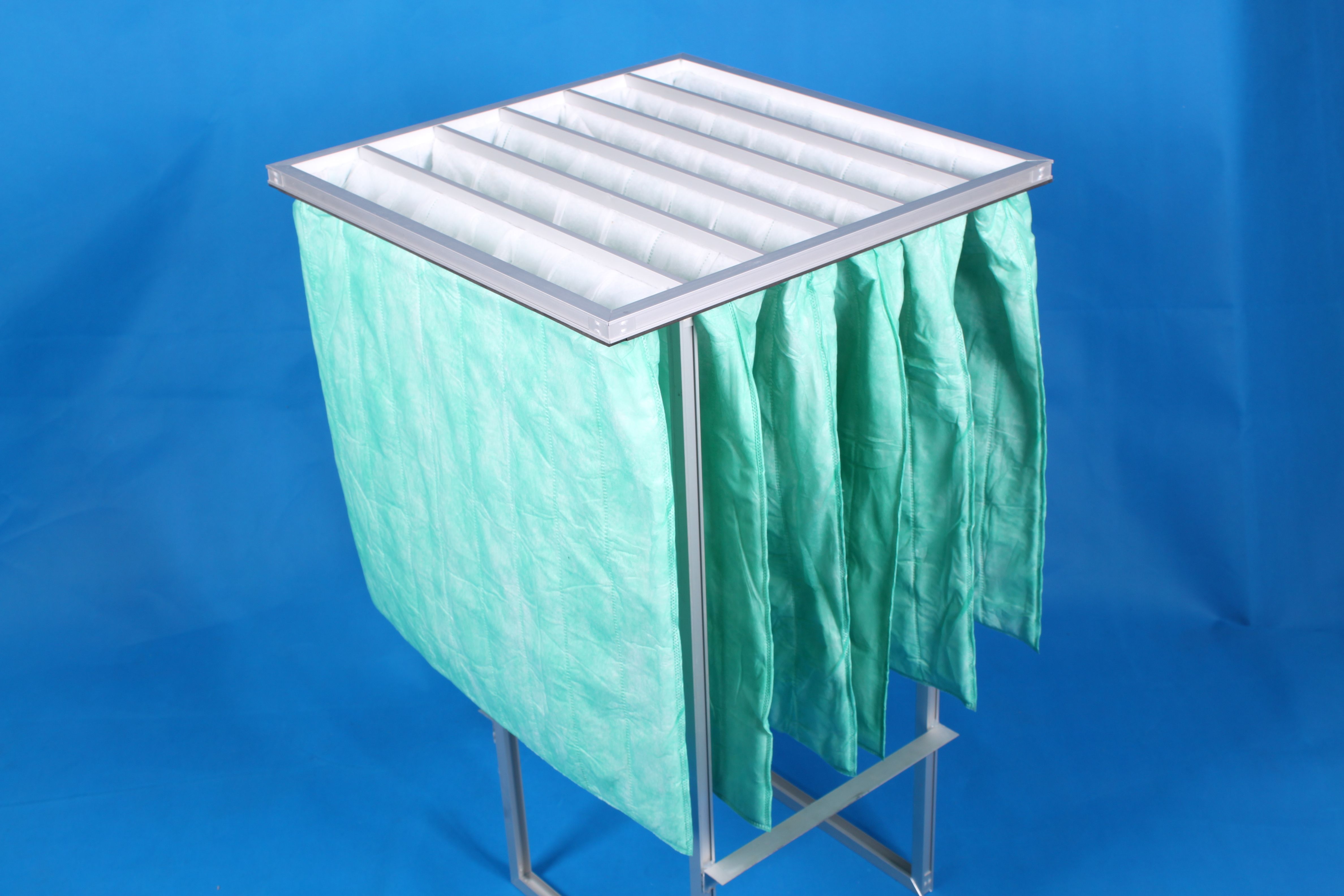

Primary Pocket Filter

Features:

- Firm Metal Frame Structure

- High Dust Loading Capacity, Low Pressure Drop

- High Quality Multilayer Non-Woven Synthetic Fiber Filter Media

- Ultrasonic Sealed Pocket Structure

- Efficiency : G3,G4

Product Description:

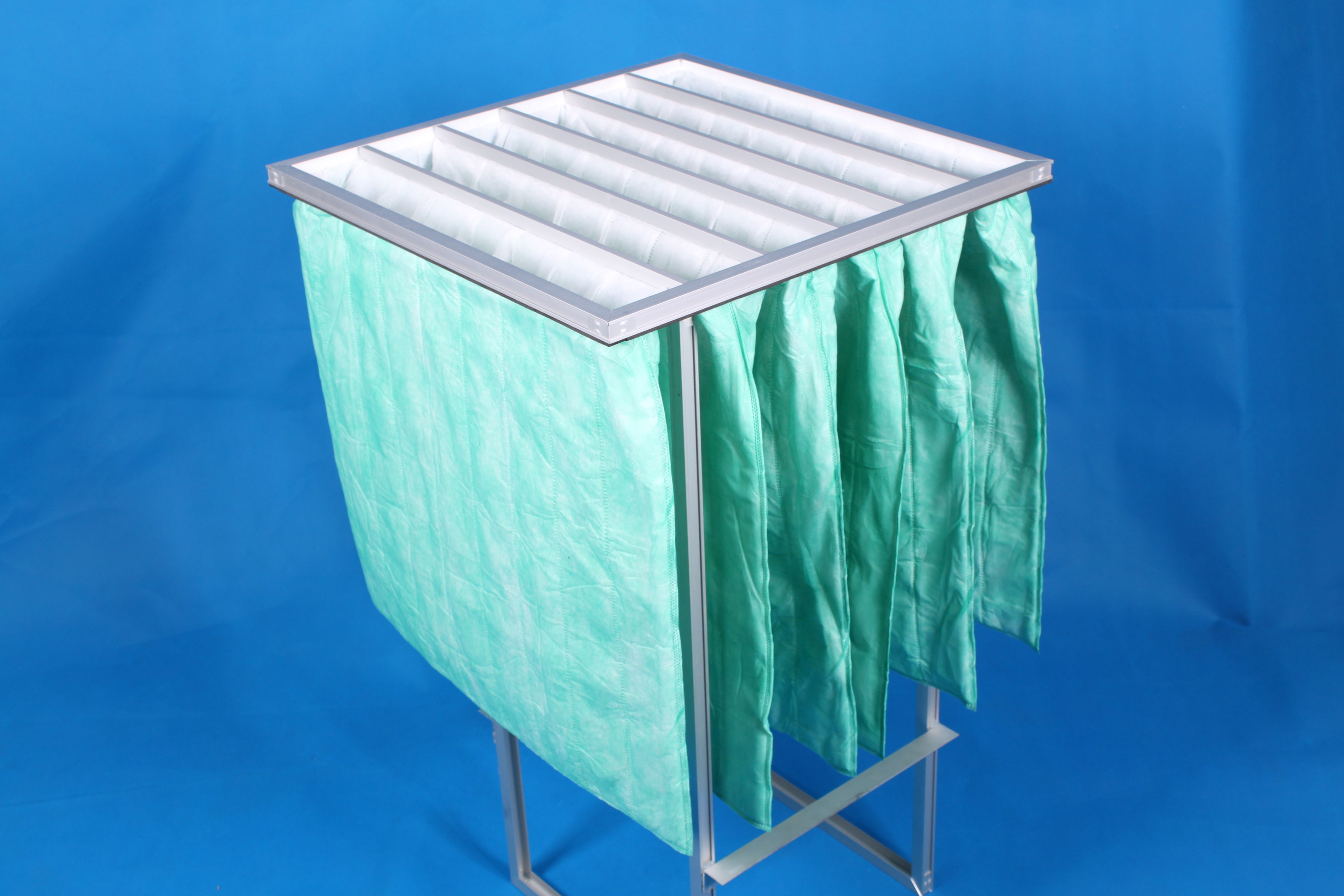

The Extended Shape of The Filter is Specially Designed for Better and Steady Air Filtration Efficiency. The Dimensions of The Filter can be Altered based on clients requirements. Pocket filter is applicable to clean room system of food industry, Pharmaceutical Industry, Electronics Industry And Ventilation System of Industrial Plant as Well as Commercial Building.

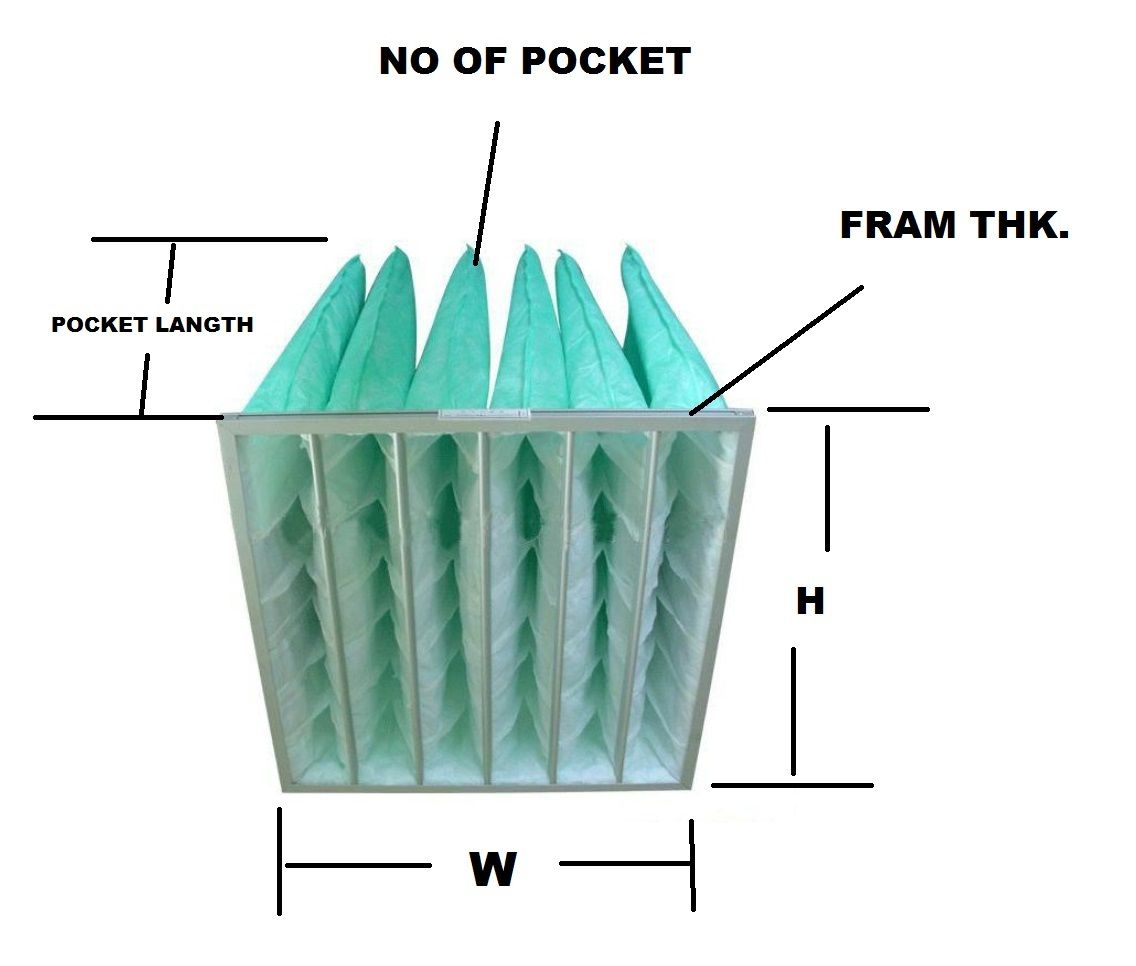

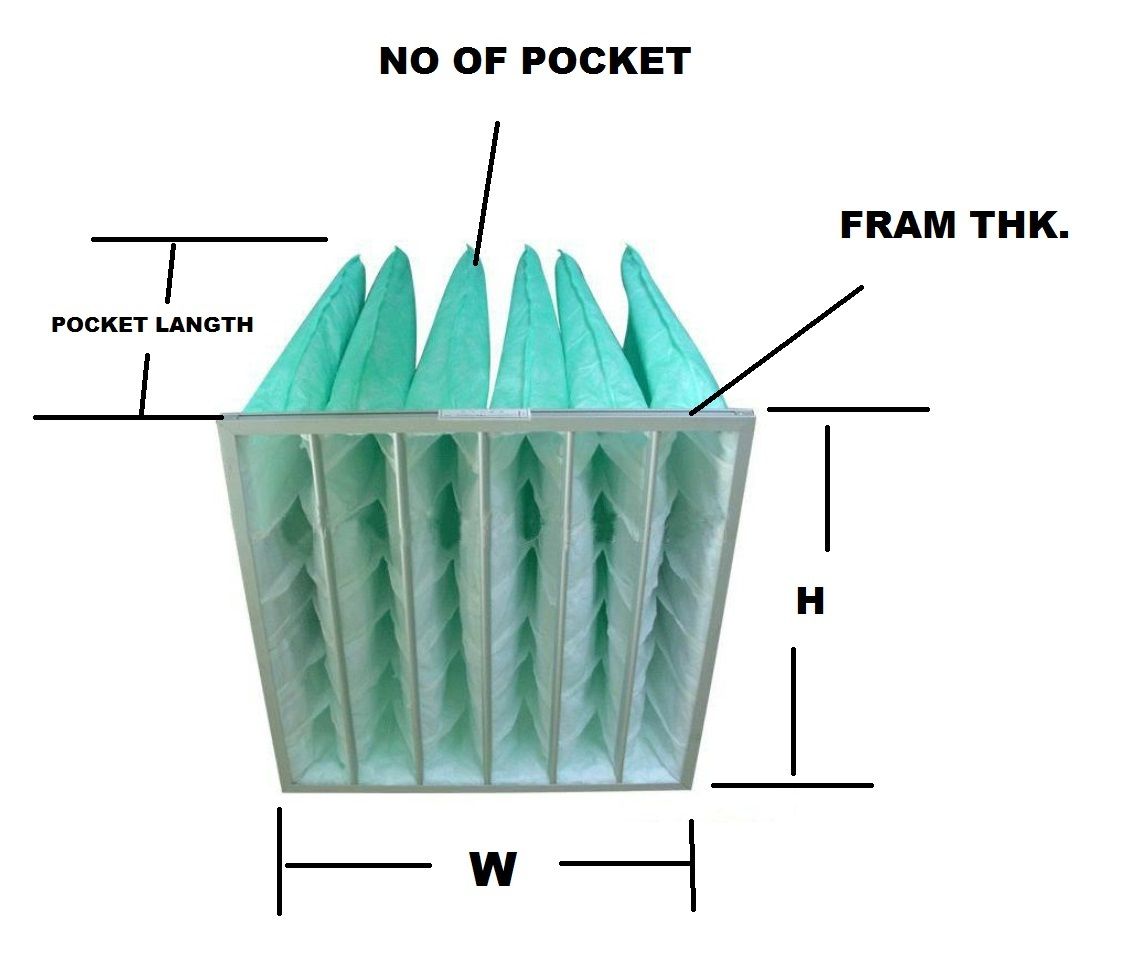

Structure Description :

- Firm Metal Frame Structure . The outer frame of MPack is made of double layer U-shape aluminum alloy sheet. The pockets are sealed tightly by special knots in the rib supports within the frame to prevent drop off. All the metal sides are rolled inwards to prevent scratching during installation or replacement.

- High Quality Multilayer Non-Woven Synthetic Fiber Filter Media . The Media consists of 4 layers of tightly sealed non-woven synthetic fiber which have low pressure drop and high dust loading capacity. The needle-shape layer and micro-fiber layer of the media would ensure high filter efficiency.

- Ultrasonic sealed pocket structure. The three sides of pockets are ultrasonic sealed while the corner of the back empty sides are tightly sealed with glue to ensure its rigidness under harsh working environment. The pockets are supported by strengthen grids and uniformly divided into several air passages to ensure maximum expansion and uniform air flow. The pocket-shape increases the media surface area for higher dust loading capacity and lower pressure drop.

Applications :

- As a Pre-Filter in The AHU and AC Ventilation System to Prevent The Accumulation of Dust Within The System.

- As a Pre-Filter in a Huge Size Air Compressor.

- As a Pre-Filter in the AHU and AC ventilation system of a clean room to prolong the Service life of Secondary or Tertiary Filters.

- As a Main Filter in the Ventilation System of an Industrial Plant.

- As a Main filter for Big Particles Removal in the AHU or AC Ventilation System of a Building.

MODEL - ETIP-PPF

DIMENSIONS -

- 592 MM X 592 MM X 600 MM NO OF Pockets - 6 ( EN779 - G4 )

- 287 MM X 592 MM X 600 MM NO OF Pockets - 3 ( EN779 - G4 )

Customizable Filtration Solutions

Our primary pocket filters are tailored to suit a wide range of specifications, allowing customization of pocket depth, quantity, and frame material. This adaptability guarantees compatibility with different HVAC setups and application requirements, whether in pharmaceutical, commercial, or clean room scenarios. Clients benefit from enhanced air quality, reduced energy costs, and operational flexibility.

High Performance with Versatile Applications

These medium-grade filters (F5F9 EN779/ISO16890) are engineered for superior dust retention and filtration efficiency. They maintain a low initial pressure drop (60 Pa), accommodate high flow rates, and perform reliably in diverse temperature ranges. Their multi-pocket, moisture-resistant synthetic fiber media ensures longevity and easy replacement, making maintenance straightforward.

FAQs of Primary Pocket Filters:

Q: How do I choose the right pocket quantity and size for my HVAC application?

A: Selecting the appropriate pocket quantity and size depends on your air handling units specifications and the required filtration capacity. Pocket depths are customizable between 290mm and 600mm, while filters can have 3 to 12 pockets. Consult with the supplier or manufacturer, providing your flow rate, system size, and required efficiency for tailored recommendations.Q: What process should I follow to install and replace primary pocket filters?

A: Installation is straightforward due to flange or clip-on connection options. To replace filters, monitor pressure drop and replace when it reaches 250450 Pa for optimal performance. Always use filters that fit your units dimensions and consult the provided manual or support team for specific instructions.Q: Where are primary pocket filters commonly used?

A: Primary pocket filters are widely utilized in HVAC systems for clean rooms, pharmaceutical facilities, and commercial air handling units. Their versatility also suits laboratory, healthcare, and other critical environments that demand effective particulate removal and high airflow quality.Q: What are the benefits of using synthetic fiber pocket filters with a metal frame?

A: Synthetic fiber media ensures high dust holding capacity, moisture resistance, and extended filter life, while the galvanized steel or aluminum frame provides structural integrity. The combination enables efficient filtration, easy installation, lightweight handling, and reliable performance across various conditions.Q: When should I replace primary pocket filters in my system?

A: Filters should be replaced when the final pressure drop reaches 250450 Pa, or as suggested by your facilitys maintenance schedule. Timely replacement ensures consistent air quality, maintains system efficiency, and prevents overloading the air handling unit.Q: How does filtration efficiency relate to the filters color and grade?

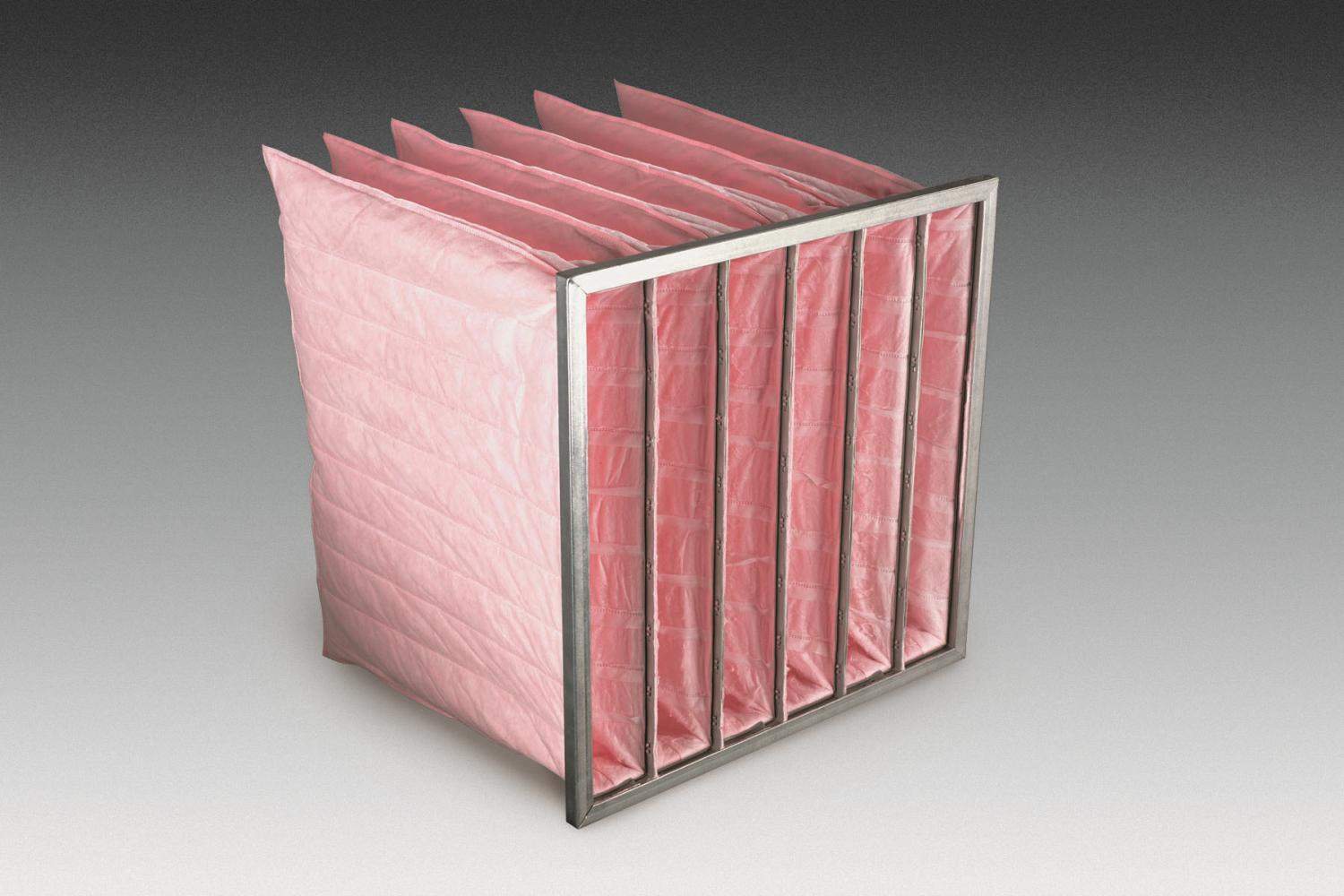

A: Filter colorsgreen, pink, yellow, and bluecorrespond to different filtration efficiencies and grades, as defined by standards (F5F9 EN779/ISO16890). Choose the color and grade based on the particulate size and air quality standard required for your application.Q: What makes these pocket filters suitable for high-capacity and demanding environments?

A: Their multi-pocket construction increases dust loading capacity while maintaining a low initial pressure drop, accommodating large volumes of air (typically 15003600 m/h). The synthetic fiber medias moisture resistance and durability ensure reliable operation even in challenging settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in POCKET FILTER MANUFACTURER IN INDIA Category

Washable Pleated Pre Filter

Price 850 INR / Piece

Minimum Order Quantity : 12 Pieces

Feature : Washable, Reusable, Long Lasting

Condition : New

Material : Aluminum Mesh and Synthetic Fiber

Shape : Rectangular or Customized

F6 Medium Effciency Pocket Filter

Price 4000 INR / Piece

Minimum Order Quantity : 12 Pieces

Feature : High dust holding capacity, low initial resistance, uniform airflow distribution

Condition : New

Material : Synthetic Fiber/Nonwoven Fabric

Shape : Pocket/Bag

F8 Medium Effciency Pocket Filter

Price 4000 INR / Piece

Minimum Order Quantity : 12 Pieces

Feature : Medium Efficiency Pocket Filter with high dust holding capacity, strong air permeability, and low initial resistance.

Condition : New

Material : Synthetic Fiber/NonWoven Fabric

Shape : Pocket/Baffle Type

F7 Medium Effciency Pocket Filter

Price 4000 INR / Piece

Minimum Order Quantity : 12 Pieces

Feature : High dust holding capacity, low resistance, large air volume, stable structure

Condition : New

Material : Synthetic fiber, galvanized steel frame

Shape : Pocket/Bag

Send Inquiry

Send Inquiry