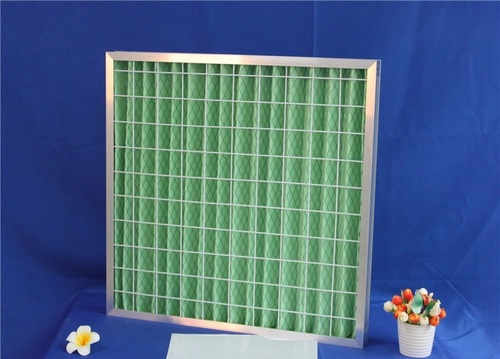

Pre Filters Ductable Unit

Price 750 INR/ Piece

Pre Filters Ductable Unit Specification

- Filter Type

- Air Intake Pre Filter

- Connecting Type

- Flanged / Box Ended

- Cleaning Method

- Washable / Vacuum

- Media Type

- Washable synthetic media

- Capacity

- Depends on filter size and unit air volume

- Temperature Range

- Up to 80C

- Efficiency (%)

- 90% @ 10 micron

- Pressure

- Initial 20 mm WG; Final 50 mm WG

- Filtration Grade

- G2, G3, G4 (EN779)

- Flow Rate

- 3003500 CFM (varies by size)

- Condition

- New

- Material

- Galvanized steel / Aluminium frame

- Mesh

- Nylon / Synthetic fiber mesh

- Diameter

- Custom as per unit design

- Construction

- Box / Flange type with supporting rods

- Medium Filter

- Synthetic non-woven / HDPE media

- Weight

- Lightweight (Varies by size)

- Shape

- Rectangular / Square

- Feature

- High dust holding, robust construction, easy installation, washable and reusable

Pre Filters Ductable Unit Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Pre Filters Ductable Unit

We are manufacturer and supplier of high quality Pre Filters Ductable Unit, and Industrial Pre Filters Ductable Unit from Ghaziabad, India. We are manufacturing and supplying Pre Filters Ductable Unit, and Industrial Pre Filters Ductable Unit to various cities like, NEW DELHI, NOIDA, GHAZIABAD, MEERUT, SONIPAT, MANESAR, GREATER NOIDA, KANPUR, AMBALA, LUDHIANA, PAONTA SAHIB, MUZAFFARNAGAR, RANCHI,PATNA, JAIPUR, JAMMU, INDOR, GUJARAT, AHMEDABAD, MUMBAI, PUNE and many more.

Pre filters are manufactured from high density polyethylene mesh which has excellent washable properties as compared to other filter media. Since this filter encounters maximum dust loading, such washable property ensures longer service life of the filter. These filters can be offered in non woven synthetic media and can be supplied either in flange type or box (cassette) type construction. The filter can be supplied in MS, Aluminium or Stainless Steel frames.

Technical specification

| Pre Filters 10 Microns | Pre Filters 20 Microns |

|

|

| Size inches | Flow (cfm) | Size in inches | Flow (cfm) |

| 24 x 24 x 2 | 1000 | 24 x 24 x 1/2 | 500 |

| 24 x 24 x 4 | 2000 | 24 x 24 x 2 | 2000 |

| 20 x 20 x 6 | 1600 | 24 x 20 x 2 | 1600 |

| 24 x 24 x 6 | 2300 | 20 x 20 x 2 | 1400 |

Versatile Filtration for Demanding Applications

These pre filters are engineered for a wide range of HVAC settings, from pharmaceutical environments to food industry clean rooms. With customizable sizes, depths, and shapes, they can be seamlessly integrated into air handling units, ducts, and other critical ventilation systems, ensuring superior performance in controlling air quality wherever precision is required.

Durability and Easy Maintenance

Constructed with galvanized steel or aluminium frames and finished with powder coating or anodizing, these filters are highly resistant to corrosion. Their washable and reusable synthetic media help reduce operating costs while supporting eco-friendly maintenance routines. The filters robust design promises a service life of 36 months depending on usage conditions, minimizing frequent replacements.

Efficient Air Flow and Superior Dust Holding

Boasting a filtration efficiency of 90% at 10 microns and supporting flow rates from 300 up to 3500 CFM, these pre filters excel at trapping dust and airborne particles. Suitable for environments with high humidity levels (up to 100% RH) and operational temperatures up to 80C, they maintain HVAC system performance and protect sensitive equipment and processes.

FAQs of Pre Filters Ductable Unit:

Q: How are these pre filters installed in HVAC systems?

A: These pre filters are designed for quick and secure installation inside the duct of an HVAC system, air handling unit, or ventilation line. Mounting options include clamp, tray, or slide-in configurations, and they can be either flanged or box ended depending on your system requirements.Q: What materials are used in the construction of these filters?

A: The frame is made from galvanized steel or aluminium, ensuring durability and resistance to corrosion. The filtration media typically consists of washable synthetic non-woven or HDPE material, supported by a strong metallic frame and rods for robust performance.Q: When should the pre filter be cleaned or replaced?

A: Service life is typically between 3 to 6 months, depending on environmental dust load and operational hours. Its recommended to either wash or vacuum the media when a significant drop in airflow or an increase in pressure is observed. Final pressure of 50 mm WG indicates the filter may need cleaning or replacement.Q: Where are these pre filters most effectively used?

A: They are ideal for application in clean rooms, pharmaceutical and food processing facilities, air handling units, and various ducted HVAC setups that require effective air intake filtration to maintain indoor air quality and protect downstream equipment.Q: What benefits does the washable synthetic media provide?

A: Washable synthetic media extends the filters lifespan, reduces maintenance costs, and supports sustainable operation. It allows for multiple cleanings, maintaining filtration efficiency while minimizing waste and operational expenses.Q: How does the filters construction support high dust holding capacity?

A: A combination of a sturdy frame designbox or flange type with supporting rodsand high-efficiency mesh media enables these filters to capture a significant amount of dust before cleaning or replacement is necessary. This results in longer intervals between service cycles and sustained system performance.Q: What filtration grades are available and what do they signify?

A: The filter comes in G2, G3, and G4 grades (per EN779 standards). These grades represent varying levels of filtration, with G4 providing the highest efficiency among the three, ideal for use cases demanding superior removal of fine particulates at air intakes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filter Manufacture From India Category

Pharma Industrial Filters

Filtration Grade : Other, Precision Filtration

Condition : New

Shape : Cylindrical

Material : Stainless Steel

AHU Pre Filter In Singrauli Madhya Pradesh

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Filtration Grade : Pre Filter

Condition : New

Shape : Square

Material : Galvanized Steel, Aluminum Anodized,SS304

AHU PRE FILTER In Chalisgaon Industrial Area Growth Center Maharashtra

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Filtration Grade : Pre Filter

Condition : New

Shape : Square

Material : Galvanized Steel, Aluminum Anodized,SS304

AHU PRE FILTER In Nalgonda Telangana

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Filtration Grade : Pre Filter

Condition : New

Shape : Square

Material : Galvanized Steel, Aluminum Anodized,SS304

Send Inquiry

Send Inquiry