Poultry Evaporative Cooling Pad

Poultry Evaporative Cooling Pad Specification

- Automation Grade

- Manual

- Humidity Range

- 50% - 95%

- Technology

- Evaporative Cooling Technology

- Power Source

- No direct power required

- Filtration Property

- Dust Filtration

- Surface Finish

- Smooth / Corrosion Resistant

- Shape

- Rectangular / Panel Type

- Application

- Poultry House, Livestock Barns, Greenhouses

- Accessories

- Aluminum / Galvanized Frame, Water Distribution Pipe

- Noise Level

- Silent / Noise Free Operation

- Mounting Type

- Panel / Wall Mount

- Air Flow Capacity

- Depends on fan selection

- Features

- Honeycomb Structure, High Water Retention, UV Resistant, Long Service Life

- Energy Efficiency Rating

- Highly Energy Efficient

- Coverage Area

- Customizable as per requirement

- Material

- Cellulose Paper

- Type

- Evaporative Cooling Pad

- Power

- N/A (Passive system)

- Capacity

- High evaporative capacity

- Installation Type

- Wall Mounted

- Usage

- Poultry Farm Cooling

- Function

- Temperature Reduction through Evaporation

Poultry Evaporative Cooling Pad Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Domestic Market

- All India, Rajasthan, Uttar Pradesh, Odisha, Goa, Andaman and Nicobar Islands, Gujarat, Haryana, Chhattisgarh, West Bengal, Jammu and Kashmir, Karnataka, Tamil Nadu, Delhi, Sikkim, Punjab, Tripura, Pondicherry, Lakshadweep, Arunachal Pradesh, Maharashtra, Meghalaya, East India, Andhra Pradesh, Mizoram, Central India, North India, Manipur, Bihar, Dadra and Nagar Haveli, Himachal Pradesh, Daman and Diu, South India, Telangana, Kerala, Assam, Madhya Pradesh, Chandigarh, Uttarakhand, Jharkhand, West India, Nagaland

About Poultry Evaporative Cooling Pad

Poultry Evaporative Cooling Pad

- ENVIRO TECH Poultry Evaporative Cooling Pad are used in most of the Poultry Farming and Poultry Industry. Poultry Equipment consultants and fabricators always trusts on economic and best cooling conditions with ENVIRO TECH Cooling Pads.

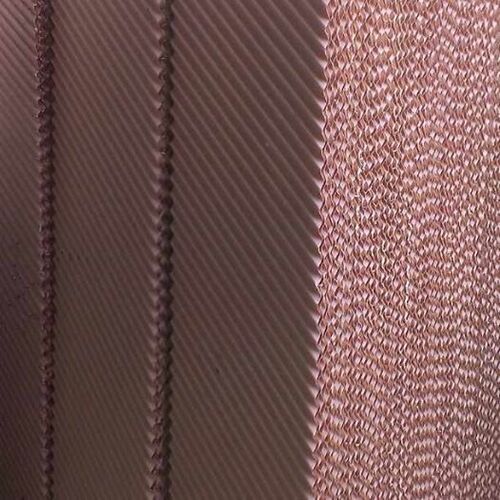

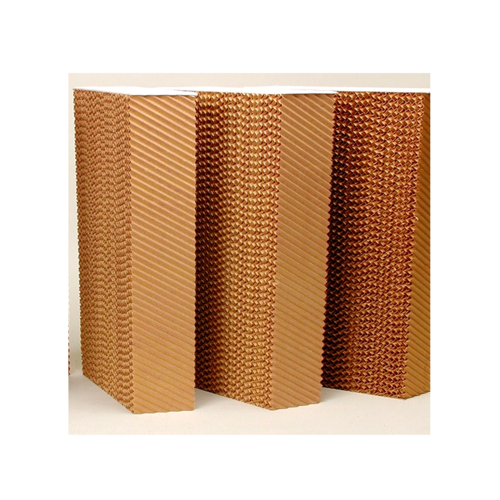

- Poultry Evaporative Cooling Pad are made of fluted cellulose sheet those are glued together. Cellulose sheet is treated with unique ingredients to achieve high cooling efficiency & degradation resistance.

- As hot air passes through the ENVIRO TECH Evaporative Cooling Pads, a stream of cool and refreshing air is produced.

- ENVIRO TECH model 5090 & 7090 Evaporative Cooling Pads are developed to provide exceptional wetting properties and air flow to achieve optimum cooling capacity and maximum durability. Our cooling pads are your best choice!

- The cooling pad acts as a device that cools air through the evaporation of water.

- ENVIRO TECH Cellulose Cooling Pads differs from typical traditional air conditioning systems and Evaporative cooling Pad works by employing waters large enthalpy of vaporization.

Applications where ENVIRO TECH Cooling Pads are used

- Greenhouse & Horticulture industry

- Vegetable Storage

- Mushroom Farming

- Seed Farming

- Floriculture

- Poultry & livestock

- Poultry Farms

- Livestock

- Hatcheries

- Dairy Farms

- Industrial & comfort cooling

- Cooling Fan

- Precoolers

- Industrial Humidification

- Residential Cooling

Cooling Pads reduce the temperature inside of buildings. Earlier Water saturated cloth sacks were placed in openings in the structure of the building. As warm air entered, it passed through the sacks and was cooled. Evaporative coolers have been used in warmer climates. As the effects of global warming are the use of Evaporative Coolers is becoming more widespread.

On days when heat or humidity , excess pollen causes discomfort, people often head off to lakes or the seaside in search of relief. Evaporative air cooling is, in many ways, simulating the cooler conditions so often found at or near large expanses of water. It makes it possible to effectively cool factories, warehouses, offices and many other areas . When sitting in a breeze people feel cooler.

The same is the case for Poultry Farming, where each and every Bird Life is considered equal to Human Life.

Advanced Cooling Technology for Poultry Environments

Engineered with evaporative cooling technology, these pads feature a honeycomb cellulose structure for maximum water retention and consistent cooling performance. Ranging in thickness, color options, and customizable dimensions, they offer flexibility to suit varied livestock housing setups in India and beyond.

Superior Durability and Energy Efficiency

With a service life of up to five years, UV resistance, and the option for flame retardancy, the pads are built for longevity. Operating without the need for direct power, they provide highly energy efficient cooling while maintaining a dust-free and odorless atmosphere thanks to their passive, maintenance-friendly design.

FAQs of Poultry Evaporative Cooling Pad:

Q: How do Poultry Evaporative Cooling Pads function in a poultry house?

A: These pads operate via evaporative cooling technology, where water circulates through the honeycomb cellulose structure. Air drawn by fans passes through the moist pad, resulting in a drop in temperature by evaporating water. This mechanism efficiently cools poultry houses, creating a comfortable environment for livestock.Q: What maintenance is required for optimal performance of these cooling pads?

A: To ensure maximum efficiency and longevity, its recommended to periodically wash the pads with soft water to remove sediment, dust, and deposits. This routine helps sustain their high water retention and evaporation efficiency throughout the 3 to 5 year lifespan.Q: When should evaporative cooling pads be replaced or inspected?

A: Pads should be inspected regularly for clogging or signs of wear, especially after heavy use or prolonged operation in dusty conditions. Replacement is generally suggested every 3 to 5 years, depending on maintenance and environmental conditions.Q: Where can these pads be installed, and are sizes customizable?

A: The cooling pads are ideal for mounting on walls in poultry houses, livestock barns, or greenhouses. Standard sizes include 1200 x 600 x 100 mm and 1500 x 600 x 100 mm, but custom dimensions can be provided to meet facility-specific requirements.Q: What are the benefits of using cellulose paper with anti-bacterial and UV resistant properties?

A: Cellulose paper with anti-bacterial treatment inhibits microbial growth, ensuring hygienic conditions inside the poultry environment. The UV-resistant property prolongs pad life by protecting against sun exposure, making them highly suitable for the harsh climatic conditions encountered in livestock facilities.Q: How energy efficient are these cooling pads, and do they require a power source?

A: The pads themselves do not need a direct power source, making them extremely energy efficient. They work passively, relying solely on water circulation and air flow from fans, which leads to significant operational cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Humidification Ventilation Cellulose Cooling Pad Wholesaler India Delhi Category

Evaporative Cooling Pad In Ponda Goa

Price 400 INR / Square Foot

Minimum Order Quantity : 1000 Square Foots

Size : 600 MM,900 MM,1200 MM,1500 MM,1800 MM

Height : 600 MM,900 MM,1200 MM,1500 MM,1800 MM Millimeter (mm)

Product Type : Evaporative Cooling Pad In Ponda Goa

Type : Industrial

Evaporative Cooling Pad Dealers In Meerut Uttar Pradesh

Price 400 INR / Square Foot

Minimum Order Quantity : 1000 Square Foots

Size : 600 MM,900 MM,1200 MM,1500 MM,1800 MM

Height : 600 MM,900 MM,1200 MM,1500 MM,1800 MM Millimeter (mm)

Product Type : Evaporative Cooling Pad Dealers In Meerut Uttar Pradesh

Type : Industrial

Evaporative Cooling Pad Dealers In Bari Brahmana Jammu

Minimum Order Quantity : 1000 Square Foots

Size : 600 MM,900 MM,1200 MM,1500 MM,1800 MM

Height : 600 MM,900 MM,1200 MM,1500 MM,1800 MM Millimeter (mm)

Product Type : Evaporative Cooling Pad Dealers In Bari Brahmana Jammu

Type : Industrial

Evaporative Cooling Pad Dealers In Kolkata West Bengal

Minimum Order Quantity : 1000 Square Foots

Size : 600 MM,900 MM,1200 MM,1500 MM,1800 MM

Height : 600 MM,900 MM,1200 MM,1500 MM,1800 MM Millimeter (mm)

Product Type : Evaporative Cooling Pad Dealers In Kolkata West Bengal

Type : Industrial

Send Inquiry

Send Inquiry