Pharmaceutical Filters

Pharmaceutical Filters Specification

- Temperature Range

- -20C to 121C

- Media Type

- Hydrophilic or Hydrophobic

- Connecting Type

- Clamp, Flange, NPT/BSP thread, Luer lock

- Flow Rate

- Up to 100 L/min (varies by model)

- Filter Type

- Sterile Air/Gas, Liquid, Vent, Syringe, Membrane Filters

- Pressure

- Max 5 Bar (varies by model)

- Efficiency (%)

- >=99.99%

- Cleaning Method

- Autoclavable, CIP/SIP compatible

- Capacity

- Up to 5000L (varies by type)

- Filtration Grade

- Absolute & Nominal Ratings

- Condition

- New

- Material

- Stainless Steel / Polypropylene / PTFE

- Mesh

- Micro porous (0.2 - 5 micron nominal)

- Diameter

- 47 mm, 90 mm, 142 mm (custom sizes available)

- Construction

- Cartridge, Pleated, Capsule

- Medium Filter

- PTFE, PVDF, PES, Nylon, Cellulose Acetate

- Weight

- As per size/design (approx. 150-800 g)

- Shape

- Round / Cylindrical

- Feature

- High dirt holding capacity, Sterile filtration, Low extractables

About Pharmaceutical Filters

Essential Use in Diverse Pharmaceutical Environments

Pharmaceutical Filters, unassailable in their performance, are widely used by laboratories, hospitals, pharma manufacturers, and process industries. They are ideal for sterile liquid and gas filtration, ensuring safe and contamination-free processes. These filters are featured for single-use or repeated use, suitable for venting, sample preparation, and critical process filtration in research, quality control, and production environmentsall while maintaining compliance and process excellence.

Sample Policy and Export DetailsValue and Trust in Every Shipment

Our Pharmaceutical Filters are available under a flexible sample policy. Shipped goods are dispatched from premier FOB ports across India to main export markets in Asia, Europe, and the Middle East. Buyers can access both the list price and competitive sale price options. Bulk and sterile-packed variants ensure products arrive unassailable in quality, meeting diverse international pharmaceutical filtration needs efficiently and reliably.

FAQs of Pharmaceutical Filters:

Q: How do I choose the right end cap type for my filtration needs?

A: The selection depends on your existing filter housing and operational requirements. Options include DOE, SOE, flat, and finned, each offering compatibility and a secure seal for various applications.Q: What sterilization processes are these pharmaceutical filters compatible with?

A: These filters are compatible with multiple sterilization methods such as Gamma irradiation, ETO, and autoclaving, making them suitable for sterile environments and diverse pharmaceutical protocols.Q: When should I use single-use versus re-usable filter variants?

A: Single-use filters are ideal for applications needing strict contamination control, while re-usable variants are better suited for routine operations with established cleaning cycles like CIP/SIP and autoclaving.Q: Where can these filters be applied apart from pharmaceutical manufacturing?

A: Beyond pharmaceutical production, these filters are also utilized in laboratory research, sterile venting, medical device manufacturing, and process filtration for liquid and gas handling.Q: What are the main benefits of procuring your featured pharmaceutical filters?

A: They offer high efficiency (99.99%), low extractables, a range of media and gasket materials, robust compliance, and the flexibility to handle multiple filtration types and challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AHU Filter Manufacture From India Category

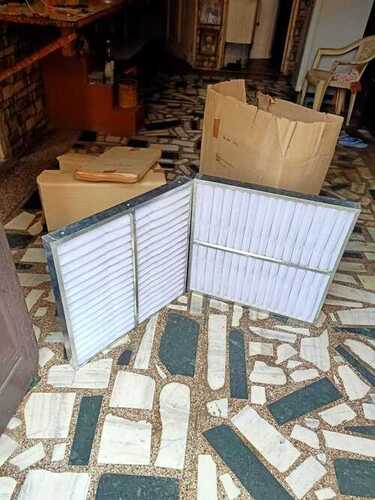

Fine Filter

Minimum Order Quantity : 12 Pieces

Construction : Other, Welded, heavyduty frame

Condition : New

Filtration Grade : Other, Fine Grade

Material : Stainless Steel

AHU Pre Filter In Krishnanagar West Bengal

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Construction : Box Filter

Condition : New

Filtration Grade : Pre Filter

Material : Galvanized Steel, Aluminum Anodized,SS304

AHU Pre Filter In Bijnor Uttar Pradesh

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Construction : Box Filter

Condition : New

Filtration Grade : Pre Filter

Material : Galvanized Steel, Aluminum Anodized,SS304

AHU PRE FILTER In Nanded Maharashtra

Price 1500 INR / Piece

Minimum Order Quantity : 12 Pieces

Construction : Box Filter

Condition : New

Filtration Grade : Pre Filter

Material : Galvanized Steel, Aluminum Anodized,SS304

Send Inquiry

Send Inquiry