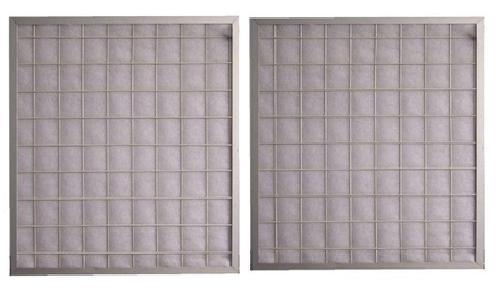

Oven Air Filters

Oven Air Filters Specification

- Cleaning Method

- Washable / Reusable

- Temperature Range

- -20C to 120C

- Filtration Grade

- Medium & Fine

- Filter Type

- Air Filter

- Pressure

- Max 120 Pa

- Media Type

- Synthetic Fiber / Metal Mesh

- Efficiency (%)

- Up to 90%

- Flow Rate

- 350 - 600 m/h

- Capacity

- Depends on oven model, typically 500 - 2000 CFM

- Connecting Type

- Drop-in / Slide-in

- Condition

- New

- Material

- Aluminum Mesh / Stainless Steel Frame

- Mesh

- Fine mesh for improved filtration

- Diameter

- Customizable as per oven model

- Construction

- Multi-layer mesh in rigid frame

- Medium Filter

- Aluminum mesh

- Weight

- Approx. 0.8 1.5 kg (varies by size)

- Shape

- Rectangular

- Feature

- High dust holding capacity, durable construction, efficient particle removal, easy to install and maintain

About Oven Air Filters

We are instrumental in manufacturing, exporting and supplying a huge assortment of Oven Air Filters to our valued clients. The offered filters are widely used in houses, offices, kitchens and many other related places for removing all kinds of bacterias and dust particles from air in an efficient manner. At our well-cleaned production unit, these filters are manufactured using top grade components, and allied materials in tandem with national as well as international quality standards. Clients can avail these provided Oven Air Filters in various technical specifications at reasonable rates.

Features:

- Less maintenance

- Energy efficient

- Longer service life

- Reliable

Frame material: GI, SS

Pleated type oven filters are available in G3, G4 and F5 grades in the depth 50 mm to 300 mm

Specifications:

| Grade | Standard Size in mm | Capacity | IPD | Dust Arrestance |

| G4 (EU4) | 610 X 610 X50 / 25 | 1600 Cmh | 70 Pa | 93% |

| G4 (EU4) | 500 X 500 X50 / 25 | 1080 Cmh | 70 Pa | 93% |

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Exceptional Durability and Filtration Efficiency

Built with multi-layer aluminum or stainless steel mesh and a solid frame, these oven air filters effectively capture fine particles while ensuring long-lasting performance even under rigorous industrial applications. Their high dust holding capacity and resistance to adverse conditions make them ideal for continuous operation in challenging environments.

Versatility and Easy Maintenance

Available in multiple thicknesses and customizable sizes, our filters can be seamlessly fitted into a wide range of industrial ovens. The slide-in or drop-in design simplifies both installation and replacement. Washable and reusable, the filters significantly reduce long-term operational costs while supporting eco-friendly practices.

FAQs of Oven Air Filters:

Q: How do I clean and maintain the oven air filters?

A: The filters are designed for easy cleaning. Remove them from the oven, rinse with water or a mild cleaning solution, gently brush off any trapped debris, and let them dry thoroughly before reinstalling. Regular cleaning, depending on environment and load, helps extend their lifespan up to 18 months.Q: What are the benefits of using these air filters in industrial ovens?

A: These filters improve air quality and equipment longevity by capturing fine particles and dust efficiently, with up to 90% filtration. Their robust construction, chemical and thermal resistance, and easy maintenance contribute to reliable industrial oven performance and reduced downtime.Q: When should I replace the air filters?

A: Typically, with routine cleaning and normal industrial usage, the filters last between 12 and 18 months. Replacement is advised if the filter shows signs of physical damage, persistent clogging, or reduced airflow, despite cleaning.Q: Where are these oven air filters commonly installed?

A: These filters are suitable for horizontal or vertical installation in industrial ovens, baking equipment, and heat treatment units across bakeries, food processing plants, and similar facilities involved in high-temperature operations.Q: What is the process for selecting the correct filter size for my oven?

A: To select the right filter, provide the oven model and required air flow capacity. Our filters are available in customizable rectangular shapes, with varying frame thickness (20mm/25mm/50mm) and sizes to match your specific equipment and application needs.Q: How does the filter handle harsh operating conditions?

A: Constructed from high-quality aluminum mesh or stainless steel with synthetic fiber, these filters resist moisture, high temperatures up to 120C, and exposure to common industrial chemicals, ensuring dependable operation in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Manufacturers In India Delhi Category

Wire Mesh Filter

Shape : Round or Cylindrical

Filter Type : Mesh Filter

Feature : High strength, corrosion resistance, reusable, easy to install

Condition : New

Construction : Other, Woven Wire Mesh

Capacity : Variable, depends on application

Box Type Hot Air Filters

Shape : Rectangular/Box

Filter Type : Hot Air Box Type Filter

Feature : High dust holding capacity, box type design, efficiency for hot air filtration

Condition : New

Construction : Other, Box Type, Rigid Construction

Capacity : Customized as per requirement

Air Filter

Shape : Cylindrical

Filter Type : Air Filter

Feature : Ecofriendly

Condition : New

Construction : Other, Durable

Capacity : Standard

HDPE Pleated Rod Type Pre Filter

Shape : Cylindrical

Filter Type : Rod type pleated filter

Feature : High dust holding capacity, Reusable after washing, Low maintenance, Rigid construction, Easy installation

Condition : New

Construction : Other, Pleated rod type

Capacity : Custom available

Send Inquiry

Send Inquiry